All about the sizes of laminated chipboard sheets

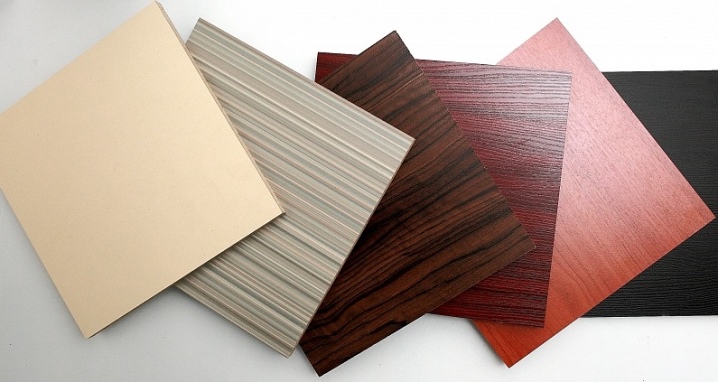

Laminated chipboard (Laminated chipboard) is a chipboard with a layer of protective laminating film applied to the surface, impregnated with waterproof and water-repellent resins. Moreover, according to GOST, only top grade chipboards with a smoothly sanded surface are laminated. Laminated chipboard compares favorably with simple ones in its moisture resistance, durability and beautiful texture at an affordable price and ease of processing.

These qualities made chipboard the most popular material for the production of furniture, finishing works.... It also finds application in the production of containers, formwork. Furniture made of laminated chipboard can be bought, or you can make it yourself according to individual sizes and with the necessary functionality - it will ideally fit into any interior and, with proper care, will last for many years. In this case, in order to calculate everything correctly, it is useful to familiarize yourself with the dimensions, weight and density of laminated chipboard.

Standard sizes

In order for the plate to withstand loads, does not break, does not bend like a paper sheet, it must have certain proportions and the ratio of linear dimensions, thickness and stiffness. Therefore, for chipboard there are certain calculated sizes. Sizes are considered standard, which are defined in GOST 33289-2013. In length it is 19 values in the range from 1830 to 5680 mm, in width 9 values from 1220 to 2500 mm:

- length – 1830, 2040, 2440, 2500, 2600, 2700, 2750, 2800 2840, 3220, 3500, 3600, 3660, 3690, 3750, 4100, 5200, 5500, 5680;

- width – 1220, 1250, 1500, 1750, 1800, 1830, 2135, 2440, 2500.

At the same time, the standard determines that the edges must be strictly rectilinear (a deviation of no more than 1.5 mm per 1 meter is permissible).

The most popular formats are 2440 x 1830 mm, 2500x1830 mm, 2750x1830 mm, 3500x1750 mm. Chipboard sheets of this format are produced by all leading companies - Egger, Kronostar, Kronospan, Swisspan, Uvadrev Holding, Sheksninsky Wood Board Plant, Cherepovets Plywood and Furniture Plant, Syktyvkar Plywood Plant and others.

The standard also allows manufacturers to determine the dimensions of products with other parameters. It all depends on the capabilities of the equipment and the needs of buyers. Sheets with the following dimensions have become typical for the Russian market: 2500x1850, 2620x1830, 2800x2070, 3060x1830, 3060x1220... They are included in the standard size range of Kronostar, Kronospan, Swisspan and other companies, and are widely represented in wholesale and retail sales. Also, small sheets with dimensions of 500x500 mm, 600x500mm are often produced.

Chipboard with non-standard dimensions can be produced according to the customer's specification. They can have special types of edges and coatings (fire and frost resistant). As a rule, such products are manufactured by order of furniture companies.

What is the thickness?

GOST defines that the minimum thickness of laminated chipboard can be from 3 mm... And then it can have any value that is a multiple of 1 mm, and is limited only by the technological capabilities of production. Usually, the equipment of most companies is configured to produce laminated chipboard with a thickness of 8, 10, 12, 16, 18, 20, 22, 25, 30, 32, 38 mm - they are considered an unspoken industry standard. Some companies also produce 19 mm slabs. And slabs with a thickness of 5, 7, 13, 17 mm are very rare and are usually made to order.

Manufacturers consider the maximum standard thickness to be 38 mm. But by special order, some companies undertake to make slabs with a thickness of 40, 50 and even 100 mm. Chipboard of increased thickness, as a rule, is used only for narrow industrial tasks. They are too heavy for ordinary furniture.

The thicker the slab, the more weight it can support.... Therefore, thin sheets (3-10 mm) are used for decorative elements of furniture, small shelves, as well as for facing rooms. For highly loaded elements (massive countertops, supporting walls of cabinet furniture, shelves for heavy things), thick sheets are used - from 20-25 mm.

The most versatile and popular are chipboard of medium thickness - from 12 to 20 mm. They are suitable for creating most furniture parts (including stiffeners for lightly loaded cabinets), as well as for decorating walls, floors, creating partitions for residential and office premises. According to the statistics of building hypermarkets, laminated sheets with a thickness of 16 mm are most often purchased.

Slab weight

It is clear that the larger the area and thickness of the chipboard, the more it weighs. But weight is determined not only by dimensions, but also:

- quality and grade of raw materials - the density of fibers of trees of different species differs, and the chip materials from them will also have different density and weight (birch is considered the most dense and high quality);

- pressing density, connecting compounds for gluing raw materials and even the geometry of the chips - the more cavities remain between the chips, and the more areas poorly impregnated with glue, the more fragile the plate will be;

- slab moisture - according to the standards, it should be in the range of 5 -7%.

Therefore, sheets with the same overall dimensions, depending on the production technology, may differ in weight, and their density (specific gravity) will also be different. In this case, it is the density that determines the permissible mechanical load and other important performance characteristics. GOST standards determine the permissible density range in a fairly wide range of 550 - 850 kg / m3. The calculated averaged values are shown in the respective reference tables. For example, the weight of 1m2 of laminated chipboard 10 mm thick will be as follows for different density values:

- 550 kg / m3 - 5.5 kg;

- 700 kg / m3 - 7.0 kg;

- 820 kg / m3 - 8.2 kg.

By how much the actual value differs from the calculated one, a professional can judge the manufacturing technology of the laminated chipboard and whether its quality corresponds to the one declared by the manufacturer. For example, the products of leading companies differ slightly from the average density values and comply with standards. For comparison, we present the mass of laminated chipboard with an area of 1 m2 and a thickness of 10 mm from the market leaders:

- Egger - 7.04 kg;

- Kronospan Russia - 7.1 kg;

- Swisspan - 7.8 kg.

If the differences from the average and standard values are significant, this indicates a violation of the production technology, such a plate will easily break and crumble, and will not withstand standard loads. The thickness and quality of the application of the laminating layer affects the weight very insignificantly - it is a fraction of a percent. But the stiffness of the top layer is the most important indicator that affects whether the fasteners will hold.

How to choose dimensions?

First, you need to take measurements and determine the overall dimensions of the product so that it fits into the intended space. Then a detailed drawing is drawn up, where the dimensions of all parts are calculated and indicated. This will allow you to correctly calculate the required amount of material, select the type of fastener.

For each part, depending on the load, there are optimal proportions. For convenience, you can focus on the typical sizes of furniture, the reliability of which has been tested by the experience of more than one generation of craftsmen. For example, for a cabinet with a standard depth of 600 mm, the recommended maximum shelf length of 16 mm should not exceed 600 mm, and for a shelf thickness of 18 mm, 800 mm.

If you plan to assemble complex furniture with a variety of functional elements and non-standard dimensions, then for drawing up a drawing it is better to use specialized programs (Cutting 3 or similar) or order a project from a private specialist, a specialized company.In this case, it will be necessary to take into account a lot of factors; it can be difficult to calculate them manually even for a professional, let alone a beginner.

The advantage of specialized programs over "manual" calculation is also that they will help you to choose the area of the sheets and the number of cuts so that the remainder is very small when cutting, and you do not have to overpay for extra material.

The cutting can be entrusted to specialized companies, who produce it on a machine, obtaining high quality edge processing. But you can cut the chipboard yourself, the main thing is to prevent cracks in the material and be sure to process the edge.

When cutting and cutting, it is important not to forget to lay a stock of material for the edge if it is planned to be more than 0.5 mm (for example, flexible or rigid PVC edging). The size of the edge can be neglected only if it is less than 0.5 mm (melamine tape, acrylic varnish, PVC-0.4).

Since a variety of sheet sizes are on sale, it is not difficult to find a material of a suitable area. Moreover, when developing standard size lines, many manufacturers are guided by the popular sizes of furniture parts. That's why for typical products, it is often not even necessary to cut anything.

For example, the size of chipboard sheets can be found already by the size of the finished countertop and with a processed edge. It is enough to purchase such a sheet, install it on the frame, attach the legs from suitable bars - and a simple dining or writing table is ready. Despite the simplicity of the design, it will look stylish thanks to the aesthetic appearance of chipboard. From a variety of options, you can choose with any surface texture, pattern, color.

Sheets with a side of 2500 mm correspond to the typical height of a wardrobe.

You can choose any area, but it is important that it is not too large - otherwise the canvas will bend, move with effort, destroying the guides.

Usually the width of such a door is not more than 1800-2000 mm. Therefore, if the cabinet is long, then it is more expedient to make 2 or 3 doors of a smaller size than one sheet of a huge area.

To give greater rigidity, the door for the wardrobe is often framed with a metal or plastic profile. This allows the use of sheets of small thickness - usually they take 8, 10, 12 mm (they are not too heavy, standard profile sizes are suitable for them). The profileless door is made thicker - 16 mm. But in any case, the weight must be consistent with the capabilities of the fastening system and the driving mechanism - the maximum loads that they can withstand can be found in the accompanying documentation.

It is also easy to find a ready-made sheet of suitable dimensions for making a bed, a headboard for a standard bed, a wardrobe. For the bearing walls of cabinet furniture, a material with a thickness of 20-38 mm is used. Small sheets are used to create shelves, bedside tables, dressers, wall cabinets. For wall cladding, small-sized panels with a thickness of no more than 10 mm are usually taken.

The comment was sent successfully.