Rules and options for cutting laminated chipboard

Laminated chipboard (chipboard) is today the main material for the mass production of furniture. This woodworking product is used not only in furniture factories, but also used by home craftsmen.

For the manufacture of furniture, laminated chipboard sheets must be cut in such a way that the material is not covered with a network of cracks or chips. Such cutting can be performed using special industrial equipment or ordinary household tools. Performing work requires certain skills and experience.

Fundamental rules

A feature of laminated chipboard is that the material has a hard protective coating, which is a multilayer film of paper with resin, pressed under high temperature and pressure. The thickness of the laminated layer of chipboard is small, but it reliably protects the material from moisture and mechanical damage. Sawing chipboard is a difficulty due to the fact that under the action of the cutting tool, the laminated layer cracks, thereby impairing the aesthetic appearance of the sheet. The width of the chips is small, but it is not always possible to eliminate them.

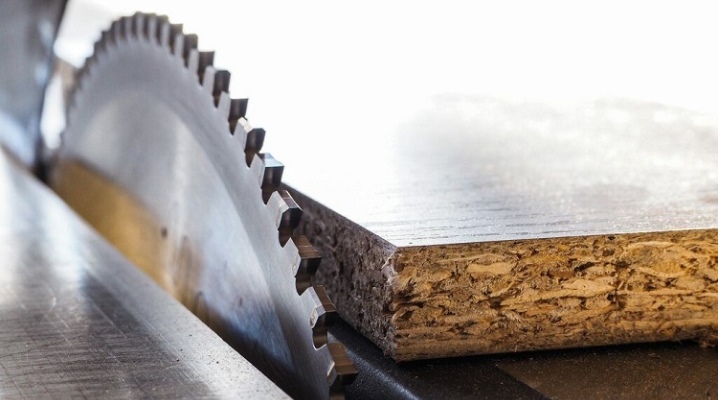

Cutting of laminated chipboard can be done using a jigsaw, circular saw or a conventional hand saw with sparse fine teeth.

To cut the material accurately and efficiently, you must adhere to the following rules:

- so that the saw teeth do not damage the laminated layer of material, adhesive mounting tape is glued to the cutting line;

- to facilitate the sawing process with a sharp knife blade, it is necessary to scratch the lamination layer until the chip layer is reached, while the direction of the blade should be tangential relative to the surface of the material;

- during the sawing process, it is important to keep the saw blade at an acute angle of 30 degrees relative to the surface of the workpiece;

- when using a power tool, work is performed at low speeds;

- on the finished part, it is necessary to cut a thin layer of the laminated part at an angle of 45 °;

- after cutting, the edge of the workpiece is filed in the direction from the periphery to the middle;

- after the edge of the cut has been filed, it is closed with a self-adhesive melamine patch strip, or it can be a C or T edging.

What might you need?

At furniture factories, laminated chipboard is cut using special equipment - usually a CNC machine, on the table of which a sheet of material is laid. The circular saw of such a machine makes a clean cut without chips. Format cutting of workpieces occurs in mass quantities, and in addition to sawing in the production process, additional devices and materials are used to process furniture parts. Most trading companies provide the population with services for sawing purchased furniture boards, but some craftsmen prefer to do this work on their own. Sawing chipboard material with your own hands at home is much more difficult. A hand file will require caution from the master and the presence of a certain tool.

It is most convenient to cut the laminated chipboard with a router or jigsaw. Cutting is most efficient with a circular saw, but choosing the right blade for a clean cut is difficult.

In addition, to work on the processing of chipboard, a special working table with leading edges is required.

When performing work with an ordinary jigsaw, in the absence of experience in working on the material, chips are often formed, since using this tool to make a perfect cut is quite problematic. The sawing process can be made easier by attaching a bimetallic laminate saw blade to the jigsaw, the teeth of which are sharpened in the inner direction. Work with a jigsaw is performed at low speeds of the saw blade feed, they do this so that cracks do not appear on the laminated surface when working.

Another way to cut a laminated chipboard sheet is to use a hacksaw blade. For work, a hacksaw for metal is suitable, which has very small teeth. For work, the blade will have to be prepared, that is, the teeth must be diluted by 0.5 along the blade thickness. The blade itself must be made of a hardened steel grade. Not all power tools are suitable for working with laminated material. It is impossible to cut this furniture board properly with an angle grinder called a grinder. The speed of rotation of the disk for this tool is very high and chips on the chipboard will be inevitable, especially if a circular disk with a large diameter is used for work.

The ways

Slices made on a sheet of wood-based material can be made in various ways.

Straightforward

At home, the task of straight-line sawing of chipboard can be carried out using certain tools.

- Jigsaw. A hand tool that can be used to cut small chipboard. A jigsaw file must be taken with the smallest teeth. The jigsaw movements should be performed without pressure and jerks, the blade feed speed is chosen as low as possible. As a rule, there are no chips on the side of the furniture board where the file with teeth entered, they can form on the opposite side of the blade. But if the sawing is done carefully and slowly, then you can achieve a clean and high-quality cut.

- Circular saw. The use of this power tool greatly facilitates the task of making a straight cut. The productivity of a circular saw is significantly higher than that of a jigsaw. For work, you will need to pick up a disc with small teeth. The working table where the circular disc is installed is usually equipped with guide rails, with which it is much easier to make an even and neat cut.

The listed tools do a good job of cutting material, but they are only capable of making straight cuts.

Curvilinear

At home, getting a curly cut is quite difficult. To complete this task, the DIYer will need a special power tool called a cutter. This device will not only help to make a curvilinear cut, but also protect the material from the appearance of chips in the process of performing the work.

The process of working with a milling cutter is as follows:

- on a sheet of ordinary chipboard or plywood, outline the necessary contours;

- using a jigsaw, cut out a part along a given contour, stepping back from it 1-2 mm for the accuracy of cutting;

- the finished template is cleaned with a file and sandpaper;

- the plywood template is applied to the chipboard sheet, securing it from all sides with clamping clamps;

- using a cutter equipped with a bearing, the material is cut, moving along the contour of the plywood template.

An electromill can have 2 or 4 cutting blades. All blades must fully grasp the working thickness of the workpiece in height.

Mixed

In some cases, in the manufacture of exclusive designer furniture, it is required to use the technique of straight and curved cutting in combination with each other. In production, this task is performed by format-cutting equipment. The chipboard sheet is laid on the desktop and fixed. The cut lines are marked on the sheet and the saw blade is started at the machine. The table at the machine is movable and automatically controlled. The sheet on the table moves towards the direction of the saw blade, which makes an even and neat cut.

At home, a jigsaw or circular saw is used to make a straight straight cut. After the straight cuts are made, a milling cutter is used and with its help the workpiece is cut along a given contour.

Cutting technology

In order to make a smooth cut of chipboard with your own hands, at home it is important not only to use the necessary power tools, but also to use additional devices that help to carry out high-quality sawing of the material.

To cut off laminated chipboard at home and get a good result at the same time, compliance with 3 conditions will help.

- You need to cut the material using a guide. For this purpose, 2 joinery clamps and a building level can be used.

- The smaller the teeth on the saw blade, the easier and better the cutting of the laminated material.

- The cutting speed should be low. If you increase the number of revolutions of the power tool, the saw blade may begin to bend, so an even cut will no longer work.

Straight cuts of laminated chipboard are made on format-cutting equipment. Before cutting, it is necessary to prepare the material for work. To do this, a straight line is scratched on a sheet of material with a knife or sharp awl along a ruler, which makes it possible to cut through the lamination layer in advance with minimal risk of chips. Next, they take a hacksaw for metal or a jigsaw and set the working blade so that it fits evenly into the previously made scratch.

After the chipboard sheet is cut, its sections must not only be sanded with a file and sandpaper. Melamine self-adhesive tape is usually glued over the cut. The cut at the corners of the workpieces is usually at 45 degrees, while the parts of the tape will need to be cut at the same angle and closely butted to each other.

Most often, laminated chipboard is used for furniture products, the thickness of which is 16 mm or 18 mm. The sectioning tape is selected according to the thickness of the sheet.

In the next video, you will find chip-free cutting of chipboard in a simple and effective way.

The comment was sent successfully.