Screw piles for a fence: features of choice and subtleties of installation

Since ancient times, people have tried to protect their territory. At a minimum, so that their private house or summer cottage avoids prying eyes. But the fence also makes it possible to protect yourself and mark the boundaries of your territory. At the same time, we must not forget that it must be of high quality, presentable, strong and have an affordable cost. And screw piles, which have already gained popularity both in Europe and in the CIS countries, are suitable for all these parameters.

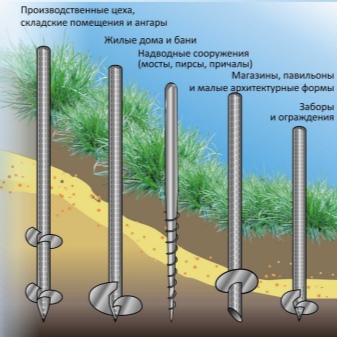

And the main feature of screw piles is that they can be safely erected in unstable soils. The supports can be installed on any soil, even in swampy areas, which is undoubtedly a huge advantage of this type of fastening.

What it is?

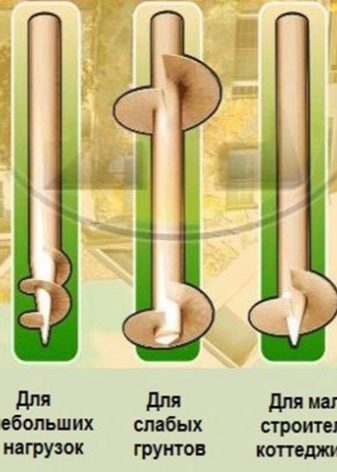

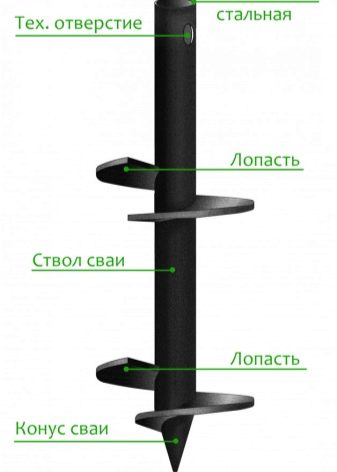

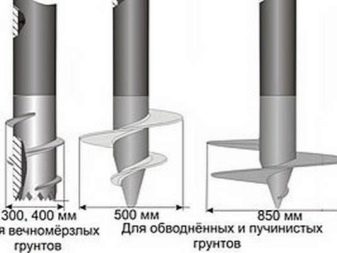

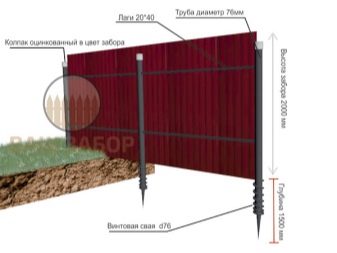

A screw pile is a metal pile that has a helical cutting blade at the end. Piles are divided according to the type of thread section. There are several types of threads: standard, paddle and combination. Piles with different types of thread differ not only in appearance, but also in what kind of load they can withstand, and how long they can serve.

Features of the choice of screw piles

The strongest and most expensive are screw piles with blades. Basically, they have two blades. Such piles, despite their high cost, are the most popular because they are the most durable, they can be placed on any kind of soil.

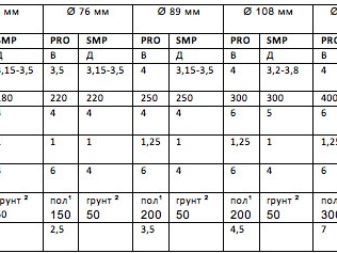

The bearing capacity of the fastening directly depends on its diameter. The thicker the diameter of the pile, the more mass the structure itself can withstand.

When choosing piles, you need to take into account the features of your future fence.

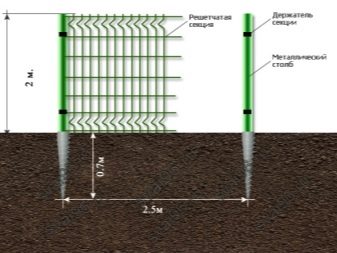

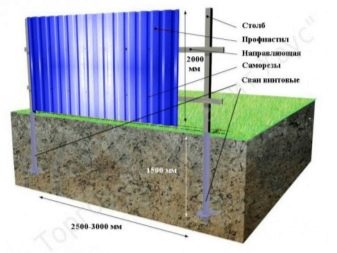

Piles with a diameter of 57-219 mm are especially popular. A smaller diameter value is suitable if you want to build a foundation for a metal mesh or picket fence. The average value is used for corrugated board fence. And the largest diameter value is suitable for heavy cladding.

The next selection criterion is the type of tip. The tip can be either welded or cast. The most durable are piles with cast tips. They are rarely bought, they are used in the construction of very heavy structures.

Next, you must decide on the length of the product. There are designs on the market from 1 meter to 11 in length. You should also pay attention to whether there is an anti-corrosion coating.

So, what you need to know to make the right choice:

- soil composition;

- the depth of soil freezing in your area;

- material from which construction will be made.

Do not forget to check the quality certificate or product passport when purchasing. The structures themselves should not have welds from welding, the corrosion coating should be applied not by handicraft, but by an industrial method.

Advantages

The most important advantage is the price of the product, since screw piles are not the most expensive on the market, with this material you save about 40-60 percent. Another plus is that one pile can withstand a couple of tons of load. You can install it yourself, as this process is quite simple.

The construction of such a fence will allow you to avoid unnecessary costs, since when erecting a fence on a strip base, you would have to dig a whole trench.And if you wanted to have a columnar foundation, you would have to dig separate holes for each column. And the main obstacle for a conventional fence would be the ability to stumble upon groundwater - all this does not matter when erecting screw piles.

You also save on filling the base with concrete. Such filling is a very difficult, but necessary stage of construction, which no longer allows you to build a fence with your own hands without special skills. All these actions are superfluous when erecting a fence from screw piles. The only thing that may be required is to tie the products together with a metal profile to strengthen the structure.

The mechanism itself can be installed at any time of the year, it is not for nothing that they are mounted even in permafrost conditions, which is undoubtedly a plus. Such a fence can freely stand for more than a century.

A plus is simple dismantling, the ability to reinstall the fence to another place.

The installation mechanism is simple, everyone can figure it out, since it is possible to screw piles into the ground without special equipment. The time that you will spend on screwing in one pile is approximately 20-30 minutes.

Preparation of materials

During installation, you will need a number of materials and tools. Choose high-quality materials, as this will envy the strength of the structure and the period that it will serve you.

There are a number of parameters to consider:

- the weight and dimensions of the material from which the fence itself will be made;

- probable wind load.

You need to purchase:

- mounting guides;

- posts for gates.

You can also purchase, if desired, the material that you will need in the future:

- mesh netting;

- forged sections;

- brick;

- wooden picket fence;

- welded mesh with a polymer coating;

- metallic profile;

- concrete spans.

Here you need to focus not only on quality, but also on design. There is a wide choice on the market - buy what you like. And always pay attention to the wind resistance, height and weight of the product, so that in the future the piles are suitable for this type of fencing.

Installation rules and tips

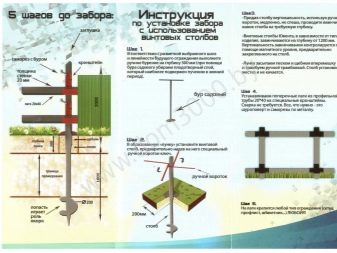

During installation, as with any type of construction work, there are often some nuances that must be taken into account. Before you start screwing in the fasteners, you need to make a trial screwing in order to determine the possible level of the structure's deepening. This will depend solely on the composition of the soil. If the soil is very hard, then the piles can be immersed to a depth of about 1.5 meters.

After that, do not forget to mark the perimeter of your fence, be sure to take into account the presence of underground utilities that can pass under your fence, so that unpleasant accidents do not happen.

When erecting a structure on moisture-saturated soils, do not forget to lay the foundation below the freezing level of the soil - this is necessary so that during seasonal changes the fastening does not "push out".

The pile driving itself can be carried out with the help of specialists (if there is a financial opportunity) or independently. To install the piles, you will need two assistants and a special gate (which you can buy or make yourself).

To create such a product, you need an armature (d = 3 cm), which is inserted into a special technological hole. On both sides, it is recommended to put on pieces of square pipe, which will act as a lever in the future. The optimal length of such a product is approximately three meters.

Experienced builders' recommendations

- If you start to feel a lot of tension when screwing in, stop. This can damage the metal.

- It is better to screw the piles in three, so that the third guides the pile and watches its direction.

- Do not use too much force if there is an obstacle on the way - you can also deform the material.In this case, it is better to use a drill, but it should be smaller in diameter than the pile.

- First, it is worth twisting the corner piles - with this trick you will achieve the evenness of the fence.

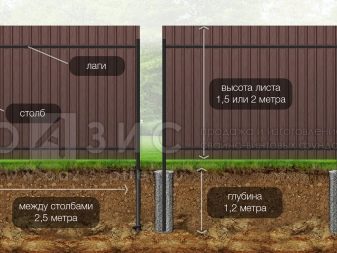

You need to calculate the number of piles, taking into account that the step between them should be about two and a half meters. Yes, in some cases it is possible to install supports three meters apart, but not more than that. Make a small indentation in the places where the piles are installed - it will help you in the future when screwing in. Place the pegs in the corners of your area, pull the thread between them.

You need to carefully adjust the verticality of the entry of the pile into the soil. This is necessary even when installing conventional posts. Otherwise, a lot of effort will need to be spent on improving the flaws and leveling the fence. It is better to use a special tool to achieve an even vertical fit.

Fence installation

So, we have come to the most crucial moment - this is the screwing in of the piles. As stated earlier, do not forget to prepare the material, the soil surface and invite two assistants. And make sure that the lever with which you will twist can withstand the load.

Check again the marking of the points for the supports and the size of the recess. Install the side posts (thereby getting used to the installation). Then you can mount intermediate piles. And remember that it is no longer possible to correct the verticality of the pile in the future.

After installing all the piles, you need to align the heads in relation to each other (for this you can use the grinder). But the depth should generally be at least one and a half meters.

Further, if you plan to install a heavy fence, use a special solution M-150. With them, you must strengthen the place where the pile exits the ground. And in any case, it is recommended to fill the cavities with concrete solution to achieve the maximum strength of the structure. Also, the fill will increase the moisture resistance of the structure. You can fill the above-ground part with a primer and an anti-corrosion solution.

Next, you need to install the guides, which will simultaneously serve as a strapping, and then proceed with the installation of the racks, to which you can attach the filling in the future.

They mainly use corrugated board, as it looks aesthetically pleasing and has a low cost.

It is better to install corrugated panels parallel to the bearing pillars. Before installing the sheet for the first time, all measurements must be made correctly in order to avoid distortions. To do this, it is better to once again hold the construction thread between the columns, along which you will be able to navigate when installing the cladding. The first sheet is applied to the log, if all measurements are correct, you can fix it. Fasten all subsequent sheets, focusing on the previous one. It is better to measure it several times in order to avoid an unpleasant bias at this stage of the work.

After fixing the cladding, you can proceed with the installation of the gate and wicket.

Driven pile posts or their brick counterpart have only positive reviews. Follow the installation instructions carefully, and the fence will last you a long time, while remaining as strong.

In this article, you were able to familiarize yourself with the features of the choice of piles, the intricacies of installing a fence and a guide on how you can build a fence yourself. If the fasteners are installed correctly, your fence will last for years. It is because of the low price and reliable quality that piles are so popular in the building materials market.

For information on how to put a fence on screw piles yourself, see the next video.

The comment was sent successfully.