Welded galvanized mesh for a fence: subtleties of choice

The modern market offers a wide selection of materials for the construction of various types of fences. One of the most popular is a galvanized welded metal mesh. This simple material owes its popularity to a number of its features and advantages. We will talk about them in our article.

Peculiarities

This type of wire mesh is made of smooth or corrugated wire drawn from low carbon steel. During production, perpendicularly spaced wire rods are spot welded at the joints.

A similar material is used for the installation of protective structures:

- in summer cottages and household plots;

- cells and aviaries;

- construction objects.

The main feature of the metal mesh is that it freely transmits the sun's rays without shading the space. At the same time, it is flexible enough that it allows it to take various forms. In addition, it does not require the construction of massive foundations, which significantly reduces the cost of installing fences.

Advantages and disadvantages

The use of a welded galvanized mesh fence has a number of advantages. The main ones are:

- Simple installation. At the same time, no special equipment is required for installation - ordinary tools that are available in every household are enough. Cope with the installation is quite within the power of any owner.

- Possibility of erecting a low fence (up to 50 cm).

- Construction of fences of various shapes and configurations.

- Aesthetics. The mesh fencing itself is neat and does not disturb the surrounding landscape.

- Security. The guardrail has no sharp corners or protrusions that could cause injury.

In addition, the welded galvanized mesh has the following characteristics:

- Strength.

- No sagging. Even with prolonged use, such a fence will not lose its shape and will not bend under its own weight.

- Resistant to temperature extremes and precipitation. Thanks to the zinc coating, the steel wire is reliably protected from moisture, wind and other phenomena that can contribute to the destruction of the metal.

All this makes the metal welded structure rather durable and reliable. In addition, the mesh belongs to the most budgetary options for fencing.

As for the disadvantages of this type of fence, they include the same openness - the mesh fence is not able to hide the interior space from prying eyes.

Manufacturing technology

Welded galvanized mesh can be manufactured using various technologies:

- Wire rods are welded together, and then the entire structure is covered with a protective zinc layer.

- Initially, the wire is galvanized and only after that it is assembled into a mesh.

In the second case, zinc covers the rolled metal products more evenly at the lowest cost. However, in the first version, the coating reliably protects not only the material itself, but also the welding places, which are most susceptible to corrosion.

Also, galvanizing itself can be performed in various ways:

- In the first case, a galvanic deposition method is used - zinc is deposited on the surface of the wire when immersed in an electrolytic solution. As a result, a protective layer with a thickness of 10-20 microns is formed on the metal.

- In the second, the material is immersed in molten zinc, as a result of which a coating is formed with a thickness of 40-60 microns and more.

The second option is considered more effective, since zinc not only covers the surface of the wire, but also penetrates into the upper layers of the metal. Thus, its protective properties are enhanced several times. However, at the same time, a metal mesh treated with a zinc melt is much more expensive than the one that has undergone galvanic treatment.

In some cases, galvanized welded mesh is additionally applied polymer coating (most often polyvinyl chloride is used for this). This procedure further increases the protection of the metal, extends the service life and improves the aesthetic qualities of the material.

The galvanized fence with additional polymer protection does not require painting and can be easily cleaned from dirt.

Dimensions (edit)

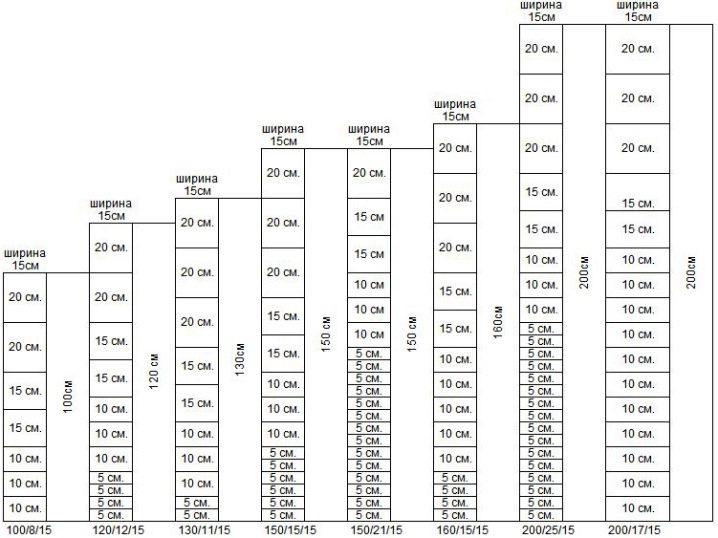

Welded galvanized meshes differ from each other not only by the production method and the method of galvanizing, but also by the parameters. So, they can be different:

- Mesh sizes (distance between longitudinal or transverse wire elements). The most common cells are 25x25, 50x50, 100x100 and 150x150 mm. However, there are also grids with rectangular cells and larger squares (up to 300 mm).

- The diameter of the wire itself. It can vary from 3 to 6 mm (in some cases, wire up to 8 mm is used).

- Length and width (height) of the mesh fabric.

This variety allows you to choose a material suitable for various purposes (the basis for hedges, land surveying or installation of a cage for animals).

For additional convenience of consumers, manufacturers offer galvanized welded nets in two different configurations: in cards and in rolls. The material in rolls is characterized by smaller wire diameters, ease of transportation and ease of installation. Welded mesh in cards, in turn, is characterized by greater strength and durability.

How to choose?

Conventionally metal meshes with welded cells and zinc coating can be divided by purpose of use:

- for summer cottages;

- for sports facilities;

- for industrial facilities.

Depending on the purpose for which the mesh will be used, its parameters and characteristics depend:

- So, for arranging a fence in a suburban area, a mesh with a diameter of rods from 4 to 4.5 mm, a height of 123 to 203 cm can be used.

- For fencing playgrounds and sports grounds for children, as well as the territories of various institutions, a fence made of wire with a thickness of up to 5.5 mm (but not less than 4 mm) and a height of 123 to 224 cm is suitable.

- Industrial zones are fenced with fences with a rod thickness of 4.5-5.5 mm and a height of 2.03 meters.

Installation of the fence

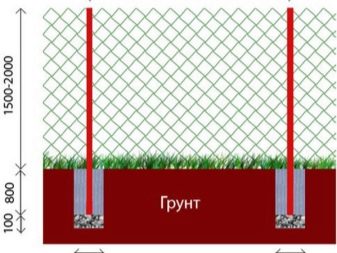

In addition to the mesh, to install the fence, you need supports (they can be round or square), equipped with plugs, and fastening elements.

There are various ways to build a fence:

- Hammer. The basis of such a fence are round supports driven into the ground and buried at least 1 meter.

- Using a columnar foundation, to which the supports are attached with anchor bolts.

- Partial or complete concreting. With this method, each hole in which the support post is installed is poured with concrete to increase stability and strength. This method is most often used on sandy soils.

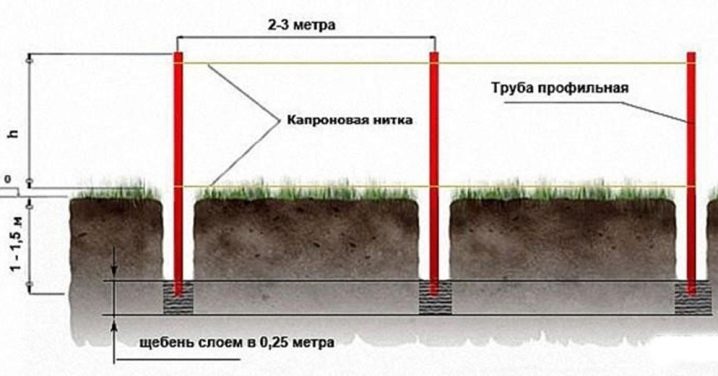

- Shooting with rubble. Suitable for areas with high groundwater levels and moving soils. The method consists in densely laying rubble or gravel around the support. Backfilling is done in small layers, which are carefully tamped and additionally covered with sand.

As with the installation of any fence, the installation of a mesh fence begins with the clearing of the area and its marking.

In this case, the size of the sections (the distance between the supports) should not exceed 2.5 m, and the supports should be deepened at least 1/3 of their length.

For information on how to install a fence from a welding mesh, see the next video.

The comment was sent successfully.