Sectional mesh fence

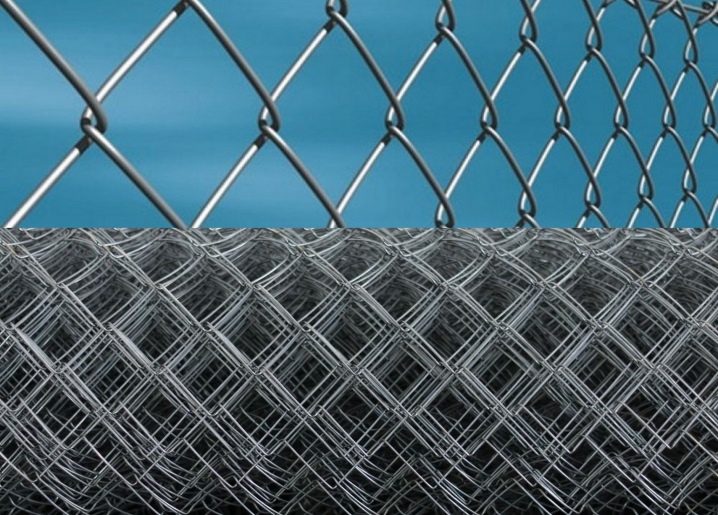

The chain-link mesh is a strong structural material. It is made on a simple machine by screwing several wires into each other, which contributes to the high quality of the product and its strength. Low-carbon steel wire is used as raw material for the mesh production.

Peculiarities

This structural material was developed in 1878. At that time, the product had hexagonal cells (sections). The production of a chain-link mesh does not require high costs for materials and equipment - one simple machine and low-carbon steel are enough. Today, there are two visually different types of sectional chain-link - rhombic (with an acute angle of 60 degrees) and square (weaving angle of 90 degrees).

Standard non-galvanized wire can last more than 7 years, galvanized wire - from 10 to 20 years.

The main advantage of the material is the speed of assembly and disassembly of the product. In a short time, you can enclose any structure around the perimeter on your own with virtually no effort. To carry out the installation, you will need a simple set of tools that every man has. The most difficult thing will be to carry out the necessary calculations for the amount of material, width and height of the supports.

The pleasant appearance of the product also cannot be overlooked. The plastic mesh-chain-link is painted in various colors: white, green, blue, purple, orange, red and many others. If we compare the chain-link with other structural materials that perform similar tasks, then the chain-link will have a clear advantage both in price and quality. All this indicates the absence of obvious flaws in this material.

Scope of application

Nowadays, the netting-netting can be found everywhere: in the fencing of vegetable gardens, school grounds, construction sites, in private guarded objects, dachas. This mesh is used because of its main quality - shape retention, stability in all weather conditions, as well as ease of self-assembly and disassembly.

Most often, special structures are fenced with a chain-link (therefore, the product is often called a fence mesh), for example, mines with coal, oil and gas fields, mines, and the like. Often, such a fence can be found on school grounds, on the construction of any objects.

Also, the chain-link is widely used by summer residents. They fence their territory with a netting, thereby separating their possessions from strangers. It often happens that an animal can enter your garden, and this is where the netting can help. Often this mesh is used in construction, strengthening walls or floors when plastering. When erecting cages for pets (chickens, roosters, goats), a chain-link mesh is also used. Moreover, this product can not only protect something, but also decorate fences, wickets and even entrance doors.

This is done by cutting off the mesh itself and, of course, additional tools that will give the product the desired shape.

Mesh types

The chain-link mesh, depending on its type and cost, has various properties, for example, corrosion resistance, durability, wire thickness, and so on. The chain-link is divided into four main types.

-

Black metal. This variety is the most affordable, hence its not the best properties come from - after several years the metal begins to rust heavily and lose its properties.In order to prolong the life of the product, it is recommended to treat it with a special varnish that retains moisture.

- Galvanized. A similar version of the chain-link mesh has great resistance to bad weather (rain, snow are not terrible), is not afraid of corrosion, thanks to a special protective zinc coating. It has an attractive appearance (pleasant silvery shade) and does not need to be treated with additional protective varnishes.

- Polymeric. Differs in high density of wire weaving, as well as beautiful appearance. It costs a little more than the usual black-metal mesh netting, but its quality justifies the cost.

- Plastic mesh. This material is budgetary, but the quality of the product itself does not suffer - it is also resistant to various weather conditions and ultraviolet light. And the appearance of this mesh is incredibly beautiful and immediately stands out from other types of mesh-netting.

How to install?

Consider ways to quickly and reliably install a chain-link mesh with your own hands in the place you need. Let's say right away that installing the mesh is not a difficult task, so everyone can perform the installation.

-

The first thing to do is to prepare the ground into which the supporting elements of the structure will be mounted. It will be enough to remove various debris, uproot shrubs and other plants, if they interfere.

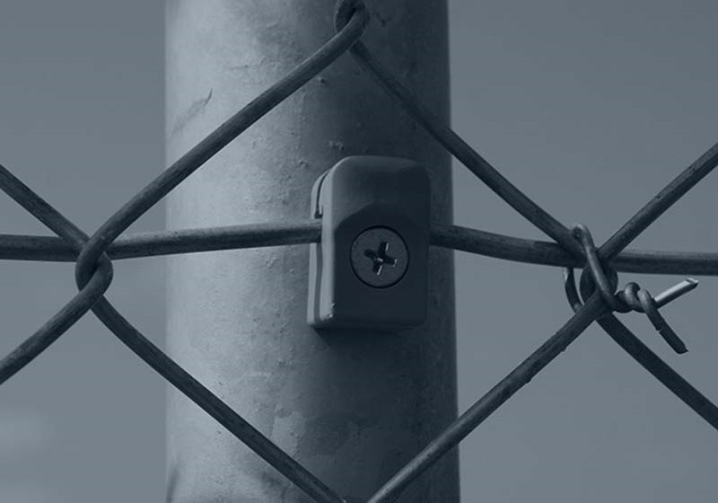

- Next, you need to dig holes under the pillars, into which it is worth mounting the supporting structures (pillars). They can be filled with concrete, covered with sand and gravel, or reinforced in other ways. It is advisable to treat the pillars with special mixtures so that weather conditions do not interfere with them in the future.

- We bury the post to a depth of about 1.5 meters, which will be a good support for our material. The most important thing is to fix the corner posts well, which will undergo a great load when the mesh-netting is pulled. One of the most correct solutions would be to install thicker and stronger pillars in the corners that will not fall at the first wind.

- After installing the corner posts, proceed with the installation of privates. The distance between them must be made approximately the same.

- Further, if there is such an opportunity, you should install special guides (wire ropes) in order to attach the mesh itself to them. Most people run the rails through the mesh in the mesh when mounting.

- After that, it remains only to fix the guides on the supports (pillars) and check whether the mesh holds well.

If the installation is planned to be carried out in areas with a clear slope, then the mesh will still have to be installed clearly horizontally (each next part must be lower than the previous one). To perform such actions, you will have to increase the height of the intermediate supports. Then it will turn out to fasten the mesh canvases at different heights from each other. Remember, the steeper the slope, the shorter the span should be.

How to make a sectional fence from a chain-link mesh, see the video.

The comment was sent successfully.