Fences with gates made of profiled sheet

Any owner of a private house or summer cottage knows how important it is to have a reliable fence around the building. Recently, profiled flooring is a popular material for its manufacture. It has an attractive and solid appearance, can reliably protect the site and owners from uninvited guests, and its cost is affordable for most people.

The article will consider the features of fences made of the specified material, their types, and also give detailed instructions for the independent production of fences from profiled flooring.

Peculiarities

First of all, we will list the main distinguishing features of a fence with a gates made of profiled sheet or a wicket made using it.

-

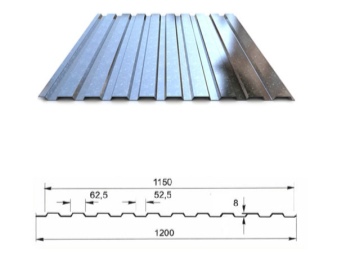

Profiled sheet is a lightweight building material. The weight per square meter does not exceed 8 kilograms, which makes it much easier to work with it. In addition, due to this characteristic, there is no need to erect powerful structures supporting the sheets.

-

Despite the lightness of the material, the profiled sheet is highly durable. It is achieved by convex ribs that are formed during the profiling process, thereby ensuring the reliability of the structure.

-

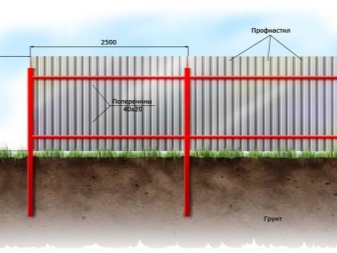

Installing a fence from a professional sheet will not be difficult even for an inexperienced builder. In order for the sheet to be securely fastened, it is enough to attach it to the 2-3rd lags with the help of special self-tapping screws.

-

The profiled sheet, despite its strength, is rather well cut and bent. Due to this, the future fence can be adjusted to the required height.

-

Due to the special technology of manufacturing the material, structures made of profiled sheet are distinguished by their durability and stability. In production, the product is treated with an anti-corrosion coating, only then decorative painting is carried out. The manufacturer's warranty is quite long - from 15 to 30 years. However, it is recommended to periodically check the fence for mechanical damage, and take measures to promptly eliminate them.

-

Attractive appearance of the fence. Modern manufacturers offer a wide range of profiled sheets with different characteristics of density, color and texture. Any of the selected varieties of this material will look good in the composition of the fence.

Species overview

Depending on the features of the installation, fences made of profiled sheet can be of different types, for example, with sliding (or with sliding) gates and with swing gates.

And also fences made of the specified material may differ in the location of the lags and lintels, for example, fences with removable or capital lintels.

Further, a more detailed description of each species will be given.

By design

Fences with sliding or sliding gates made of profiled sheet. They are fences with an opening part that moves along the fence. The main advantage of this type is space saving. This characteristic is especially relevant for small land plots.

But it should be borne in mind that the installation of such a design will take a significant amount of time and money. A fence of this type must have a particularly reliable support, therefore, it is recommended to fill a solid foundation before installing it.This will evenly distribute the load created by the moving part on the fence.

Fences with swing gates. This variety is one of the most popular, it is easy to install, does not require significant financial costs, and you can install it yourself. In addition, this design is quite robust. A fence with swing gates made of profiled sheet is a fence, the doors of which open inward or outward.

However, when choosing such a model, it should be remembered that a significant amount of free space is required to open and close the gate leaves, the presence of which only a few can boast.

This design is not always convenient to use - for example, in winter, when a large amount of snow falls, it will be extremely inconvenient to open the doors, because you will have to clear the snow blockages first. In addition, in windy weather, you need to be especially careful when closing the gate. It is not uncommon for nearby vehicles to be damaged by suddenly swung open doors.

In order not to waste physical effort to activate the gate mechanisms, their opening and closing can be automated. The components necessary for this are purchased at large hardware stores.

By location of jumpers

Removable jumpers. They are used to strengthen the fence, give it additional stability, without disturbing the appearance. Even the most stable structure is not protected from the influence of soil mobility. As a result, the fence begins to tilt and roll to one side. A removable lintel, installed between the bearing pillars of the gate, prevents unwanted micro-movements. Due to the fact that it is held by bolts, which, if necessary, can be easily dismantled, there will be no problems with the passage of freight or other large-sized vehicles into the territory of the site.

Capital lintels. They are also installed between the fence gate posts. Unlike removable jumpers, it is not possible to remove them without damaging the fences. However, due to their stronger connection to the structure, they perform the function of supporting and imparting stability to the fence in the best way. These bridges will not loosen or loosen over time.

How to do it yourself?

Beautiful gates made of profiled sheet for the fence of a private house can be easily built independently. The main thing is to draw up an action plan and adhere to it clearly. The information below will help you to do this.

Preparation

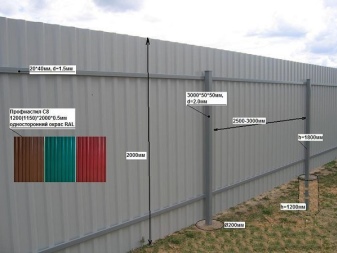

The first thing to do at this stage is to choose the appropriate density, color and texture of the profiled sheet in accordance with your needs and requirements. After that, you need to take measurements, calculate the length, width and height of the future gates. The width must be selected depending on the size of the vehicles that are expected to pass through the gate. The height may coincide with the dimensions offered by the manufacturer of profiled sheets (standard 2-2.2 meters).

When this is done, for clarity and understanding of subsequent actions, a simple schematic drawing should be drawn up on a sheet of paper indicating the dimensions of the structure on it.

Then you can proceed to the setting of support structures.

Support

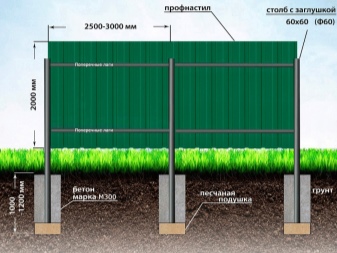

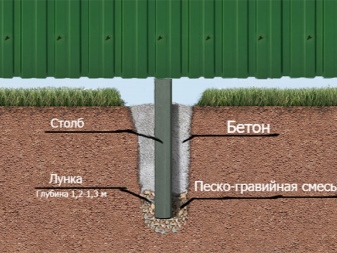

The simplest and most reliable way to install gate supports from a profiled sheet is to dig a depression in the ground with a garden drill or a shovel and then concreting the pillars. The deeper the pit, the more concrete will need to be poured into it. The optimum depth is one third of the length of the support post.

The bottom of the recess should be sprinkled with a mixture of crushed stone and coarse sand about 30 centimeters thick. Such a pillow will protect the metal from moisture and freezing temperatures.Before concreting, the support itself should be treated with an anti-corrosion coating - this will extend its service life.

The support structure must be installed strictly in an upright position. Any deviation threatens with distortion and violation of the entire structure. To avoid mistakes, you should use the building level. Only after accurate measurement can you proceed to filling with cement.

Support pillars must be protected from moisture, not only from the outside, but also from the inside. On their tops, you need to place special linings or simply fill the pipe cavity with cement.

Frame

This is one of the most important stages in the manufacture of a door from a profiled sheet. The appearance and functionality of the future product depends on how correctly it is executed.

After the supports are securely fixed, you can proceed to the manufacture of the frame of the future gate. Before that, it makes sense to double-check the correctness of the calculations performed, because after the frame is ready, it will no longer be possible to change the gate parameters.

The pre-prepared metal must be cut into frame elements. The optimum angle at which they will be welded should be 45 degrees. This will provide the most reliable fastening of the parts.

The resulting blanks must be cleaned of rust and other contaminants, and then proceed to welding. For in order to be able to check the correctness of the fastening, you can first bait the parts, and only then seal them with a continuous seam.

When all the parts are securely welded, you need to clean the seams, prime and clean the frame.

Laying corrugated board

The implementation of this stage is not particularly difficult, but even here you need to know several rules for installing profiled sheets. The covering can be laid on one or both sides of the frame. To fix the sheets, special screws or rivets are used. The first ones are the most practical, since they exclude the possibility of moisture getting into the holes, which means they extend the service life of the doors. But rivets are almost invisible on the gate, especially if they are painted to match the color of the coating.

Gate installation

When all the components of the gate are ready, you can start combining them into a common structure. The corrugated board is screwed through the lower waves to all jumpers (both horizontal and diagonal). The sheets are connected to each other through the upper convex parts by overlapping each other.

You cannot do without additional components - locks and fasteners. Modern manufacturers offer a wide range of padlocks, surface locks or mortise locks. Installation of any kind is not particularly difficult. They must be installed both in the middle and at the bottom of the sashes. This will provide an even load on the gate, as well as more reliable burglary protection.

Following simple rules, it is quite possible to independently make a fence with a gate from corrugated board in a few days.

This does not require a lot of effort and financial investment, and such a structure will serve for quite a long time.

How to make a fence with a gate from a profiled sheet, see the video below.

The comment was sent successfully.