How to make a fence on piles: technology and work procedure

To designate and protect their territory, the owners of private houses and summer cottages use fences. Also, these structures also perform a decorative function. In cities, fences are made deaf, but in villages, on the contrary, picket fences are more common, which are installed so as not to shade the ground.

Regardless of what material is chosen for the base, high-quality supports, for example, screw or driven piles, are needed to ensure a long service life of the fence.

Features of the device

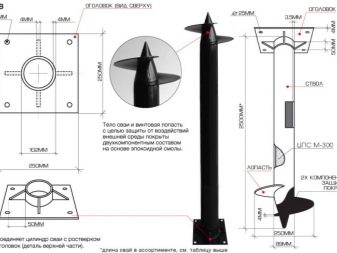

First, you need to understand what the piles are. They are solid metal pipes, threaded and empty in the middle. Blades are often used instead of threads for more secure anchoring in the ground.

A distinctive characteristic of piles is that they are easy to install. The technology and order of work are clear, you can do a lot with your own hands. To fix the screw products, they do not have to be buried or poured with concrete. Well-fixed piles are not afraid of additional loads and frosts.

A pile fence has many advantages, which is why many people choose it. However, before starting work, you should familiarize yourself with all the features of such products, find out what equipment you may need, what are the installation principles.

Advantages and disadvantages

Quality piles, like any other material, have pros and cons.

First you need to familiarize yourself with their positive sides.

- First of all, this is the ability to install such fences on heaving and swampy soils.

- When piles are immersed, the layers of soil are not mixed. This distinguishes them favorably from structures that are installed in pre-dug pits.

- When the blades enter the soil, they do not loosen it, but, on the contrary, compact it.

- Piles can be used more than once.

- Installation is carried out very quickly, since additional work (for example, pouring concrete) is not required.

- Pile installation can be carried out anywhere, even on a slope or uneven surface.

- It is possible to install a fence on screw piles at any time of the year (even in frosty winter), in any weather and without special equipment. The help of specialists is not required, everything can be done by hand.

- Screw piles are quite durable, they can withstand loads of up to several tons.

- Such a structure can stand without repair for more than a hundred years.

There are not too many disadvantages of piles, but they are still there.

- Often the installation of the supports is uneven. In this case, the fence may be skewed.

- If you use specialized equipment, then the installation of piles will be expensive. However, this disadvantage is not so terrible, because most of the installation work can be done manually.

- There are limitations regarding the screw pile installation process. Such a fence should not be placed in rocky areas. Stones can become an insurmountable obstacle to the cutting screw. Therefore, before starting work, it is imperative to do a test drilling.

Obviously, piles have more advantages than disadvantages, although all the nuances should be taken into account in the work.

Selection and calculation of load

Everyone who wants to build a house on their site is faced with the problem of choosing a foundation for a fence.The most common pile foundations are screw, driven and bored varieties. Each type has its own characteristics and advantages. To make the right choice, you need to consider them in detail.

Hammered

These are ready-made reinforced concrete rods that are designed to be buried in the soil. They are hanging and supporting. The latter rest on very dense soil layers only with a tip, while the former also use the side surfaces. Such products cost two times cheaper than bored ones. They are durable and have a high load-bearing capacity.

It is also worth considering the large weight of the structures and the need to use special equipment.

Bored

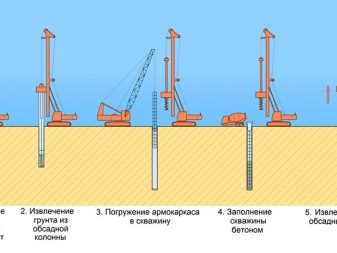

This type is a monolithic structure that consists of reinforced concrete. It is being built directly at the construction site. At the beginning, pits are drilled with the help of special elements. Steel pipes are lowered into them. A frame made of reinforcement is inserted into the cylinders that have turned out as a result of this, and then M300 concrete is poured and compacted.

Such piles have a great bearing capacity. They are quite resistant to corrosion, do not vibrate during installation, but at the same time they are expensive and have some limitation on the length of the pile. In winter, the work stops. You can put a fence only after 28 days.

Screw

Such piles do not need to be driven down to the bearing formation. It will be enough forty to sixty centimeters below the freezing mark.

When choosing, it is worth considering the following characteristics of piles:

- for permafrost soils, crown tips are used;

- for serious structures, you need to use screws with small multi-start blades;

- The optimal protection for combined structures will be an anti-corrosion coating, part of which is in the air, and part of it in the ground.

Load calculation

When constructing piles, it is recommended to consider certain parameters for loads. The pitch of the propeller should be up to five centimeters, the blade - from five millimeters thick. This will be enough for one revolution. The pipe wall thickness should be from four millimeters, the diameter can vary from forty-five to seventy-six millimeters. In addition, such a pipe must be seamless.

The piles can be up to two meters long. The tip should be cruciform, and the pipe should be cut at forty-five degrees.

For more complex, sometimes uneven terrain, it is better to screw in short piles.

Preparation of materials and markup

To install a fence on stilts, certain materials are needed. They must be of very high quality, because both the durability and reliability of the structure will depend on this. The type of tip is of particular importance. It can be cast or welded. The former are considered more long-term, although they are not bought so often. This is due to the fact that such parts are used for heavy structures.

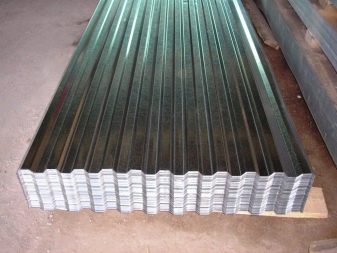

You also need to decide on the length of the product itself. There is a large selection on the construction markets (from one meter to eleven). Particular attention should be paid to the anti-corrosion coating. Also, when choosing a support, it is necessary to take into account both the dimensions of the profiled sheets and the wind load.

Necessary materials

You will need screw piles, self-tapping guides for fastening the corrugated board, posts for the gate and, of course, the corrugated board itself, the thickness of which should be about half a millimeter. After purchasing all the necessary materials, you can start marking.

Markup

The markings should go along the perimeter of the entire future fence. To do this, a cord is pulled along the perimeter of the site on the rags. The bar is nailed to two pegs that are sixty centimeters long. It is convenient to adjust the cords on them.

Since the sections of fences are usually flat, and the section can have a rather complex contour, it is necessary to take into account the length of the spans before work.All marks on the ground in those places where the piles will be screwed in can be painted with paint or lime mortar.

There is one peculiarity of screw pile installation that is worth knowing about. It lies in the fact that installation work can be carried out not only with your own hands, but also with the help of drilling rigs. Such poles can be installed at any time of the year, in contrast to work with concrete, which stops with the onset of cold weather. If there is a lot of snow on the site, then it must be removed immediately before installation.

If the winter is not very snowy, then you can immediately start drilling preparatory wells and screwing piles into them.

Installation of the pile frame

The technology for installing the pile frame can be different. It is cheaper, of course, to do the installation yourself. In this case, the piles are driven in with hammers, without excavation.

To install a reinforced concrete pile frame, a different method is used. In this case, the inventory pipes are first immersed in the ground, and then they are removed (when the holes are already filled with concrete). Also, stamping of conical wells is done, into which the concrete mixture is poured.

To install bored piles, holes are first drilled in the ground. After that, they are reinforced and poured with concrete.

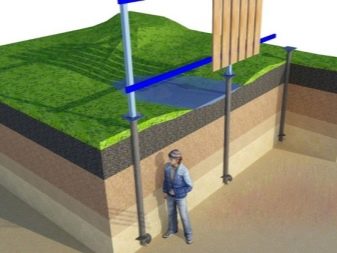

To install screw piles, installation work is carried out without welding. Steel structures are screwed into the ground using a screw thread. This method is interesting, so it is worth considering in more detail.

After completing the markings, grooves are made in the ground for screwing in the piles to accurately position them throughout the site. Pits up to 40 centimeters deep can be drilled with a tool. The main holes will directly depend on how straight the pile heads should be.

The piles themselves are not screwed into the ground very deeply, about one and a half meters. For this, a lever is made from a sufficiently long pipe. How big it will be depends on how easy it will be for the pile to enter the ground.

It is important from the very beginning to ensure that the support goes vertically, otherwise you will have to redo everything. In this case, a deviation of up to two centimeters is allowed, but only if no more than half a meter of the pile is located at the top. The resulting frame is primed to protect against corrosion.

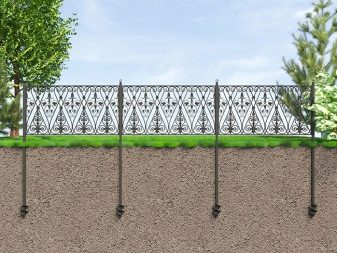

Installation of the structure

When the frame is ready, it will be possible to proceed with the installation work on fastening the material for the fence. The design can be any, for example, from a metal picket fence, from corrugated board, from bricks, from concrete.

The main bearing rails must be welded to the outside of the piles. Additional crossbeams are attached to the piles through gaskets so that their outer side is in the same plane with the main elements. If the span is longer than two meters, you need to connect them using inclined or vertical jumpers. The rungs are built up by joining pipes or corners butt.

For a fence made of a metal picket fence or a wooden picket fence, pipes with a diameter of 57 millimeters and a blade of 15 centimeters can be used. For sections made of profiled sheet, piles with a diameter of 76 millimeters and a blade of 20 centimeters can be mounted.

After that, it is necessary to fix the fence posts, to which the guides are attached. They perform the function of strapping and fill the space with a corrugated sheet or other material. You can connect the frame elements with ordinary bolts. For more reliable fastening, special brackets are used, but you can do without them.

New sheets are aligned with the previous ones and overlapped on one wave. Each element is attached with one self-tapping screw to the upper guide and only then, when the sheet is leveled, it is fixed with a second self-tapping screw. Profiled sheets are attached to the frame through a wave, while both sheets must be stitched where they join.

Where the sheets have been cut, it is necessary to cover them with bituminous mastic.

Useful Tips

The installation of piles is difficult, therefore, before installing the fence, it is necessary to study the advice of specialists with experience in such work. If the installation is performed for the first time, it is better to build a foundation for the fence at a height of up to thirty centimeters from the ground. To do this, you need to insert fence posts into the pile foundation. This will greatly facilitate the installation process.

If the fence is built from 3D panels, it is better to install them on a wooden beam. Then they need to be fixed with wooden spacers and check how carefully the work was done on the level. The construction of such fences is possible without welding. If you use special fittings or flanges, you can install the posts and fix the panels with simple bolts.

For information on how to properly make a fence on piles, see the next video.

The comment was sent successfully.