Welded mesh fences: advantages and disadvantages

The main purpose of fences made of welded mesh is to mark the boundaries of a particular area. Such fences are also used to emphasize the design of the landscape. In order to diversify the mesh fence, additional elements can be used. Such fences can be used both in private property and at industrial facilities.

Features: pros and cons

It is necessary to install a welded mesh where a blank fence is inappropriate. A mesh fence on a garden plot has a number of undeniable advantages:

- The mesh design allows air to circulate. It also does not interfere with the penetration of sunlight, which has a beneficial effect on the quality of plants.

- At cost, such a fence is more affordable than other analogues, therefore, it is optimal for small summer cottages.

- The welded mesh has a comparatively low weight, so it is easier to transport it to the installation site. The installation itself does not require special skills and does not take much time.

- The welded rod fence is quite strong, it is able to withstand a lot of weight, so it can be used as a support for climbing plants.

- The lack of windage of such a structure allows it to withstand strong gusts of wind, at the same time protecting the fenced area from unauthorized entry attempts.

- The welded mesh does not block the view, and if desired, you can observe what is happening outside the garden area through it.

- If you choose a galvanized mesh option, you will not need to maintain the fence. Thanks to the zinc layer that covers the fence bars, they do not corrode and therefore do not need to be painted regularly.

- The mesh fence has no sharp corners, dangerous parts and protrusions, so such a fence can be installed in places where there are children.

The peculiarity of a welded mesh fence is that its advantage can turn into a disadvantage. It has already been said above that such a fence is completely transparent, so the mesh is not suitable as a street fence for private estates.

Varieties

Metal mesh for fencing is made of wire of various thicknesses at the points of its weaving. The grid differs in the following ways:

- To size and the shape of cells: options are in the form of a regular rectangle or rhombus, and a non-standard trapezoid and other intricate shapes.

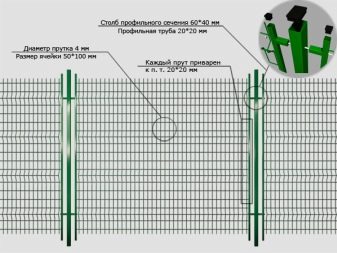

- By structure distinguish between 2D and 3D meshes. The first type is flat, has no bends and corners; cells, as a rule, have a regular rectangular or square shape. At the factory, the product is painted green, but at the request of the customer it can be repainted. The 3D mesh is stiffer due to the curvature it has. There can be 2 or more bends, they can be used as cable channels for wires.

- By type of coverage distinguish between uncoated, galvanized and polymer coated mesh:

- The uncoated variety is the most affordable. Its disadvantage is that it requires additional anti-corrosion preparation. Usually preparatory work consists in painting, and in the future, the paint must be periodically renewed.

- The second type is galvanized mesh. Distinguish between galvanic and hot zinc coating method. In the first case, the zinc layer is applied using various primers.The layer is not very strong, over time it can be damaged, which will lead to corrosion. In the second case, the layer turns out to be more durable, however, the price for such a mesh is significantly higher.

- The PVC coating is the finishing one. It is applied after the zinc layer. The result is a product that can withstand significant temperature changes and other climatic phenomena. The smaller the mesh size, the stronger the mesh.

Due to its high cost, this variety is rarely used for the manufacture of conventional barriers.

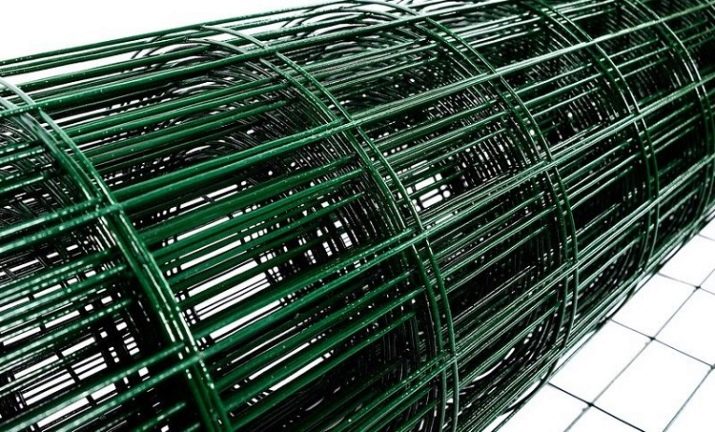

- By packing method... Welded mesh is usually supplied to consumers in rolls or cards. Coil sizes can vary in weight (from 50 kg to 0.5 tons) and length (15-30 m). The diameter of the coiled wire is relatively small, so it can be easily rolled up. This gives the mesh some transport benefits. During installation, it easily straightens and takes the desired shape. The strength of such a product is slightly higher than that of the Rabitz mesh. The cards are rectangular sheets of 1.5x2 m in size, made of extra strong wire that cannot be bent and rolled into a roll.

Application area

There are many examples of places where a welded mesh fence can be installed. In addition to the private sector, various industrial facilities are fenced with such fences. Fences are used for construction, factory and other structures; they are often used on the territory of educational and sports institutions.

From a welded mesh, you can build a fence of absolutely any length, fencing an area of different sizes. The limits depend on the budget only.

If for a small plot of several hundred square meters the most common version of the grid is suitable, then for a larger space, for example, a cottage village, a bank or an airport, a more complex version of the 3D type is most often used. In addition to the installation of fences, welded mesh is actively used in agriculture to create pens and cages for animals, as well as for fencing pastures and land.

The fence mesh is also widely used in construction: it serves as a reinforcing support for the facades of buildings, it is mounted before laying the road surface and paving slabs in order to prevent mechanical damage from excessive loads

Design

Depending on the design, mesh fences are usually divided into two types:

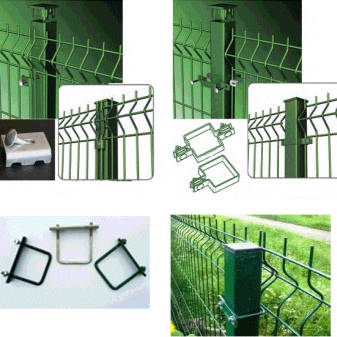

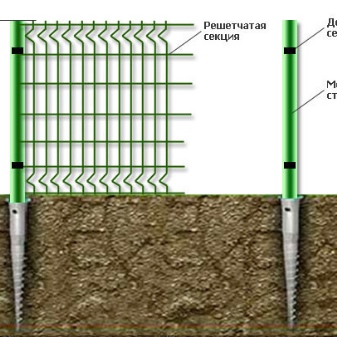

- Sectional mesh fence. It is often called European. The name "sectional" speaks for itself. Such a fence is a ready-made panel. They are supplied with fastening fittings, with the help of which the fence is assembled in a short time, like a designer. Due to their attractive appearance, such fences are often installed in parks and squares, near office buildings and in similar places.

- Tension welded fence... In this case, the tape method, roll mesh is used. Installation is more time consuming and requires an assistant. You can use concrete, wood or metal posts to support the stretch fence. Concrete poles are considered the most reliable option because they are more durable than wooden ones and do not corrode like metal ones. If we are talking about a summer cottage, then the pillars can be made independently. For more respectable places, manufacturers offer ready-made supports with hooks and other necessary fittings.

As for the distance between the supports, experts advise choosing an installation step of 2.5 m.

Installation technology

Installation of any welded mesh begins with marking the territory and leveling the surface on which the fence will be installed. To do this, it is necessary to determine the future corners and drive pegs in their places. They will fix the twine, which must encircle the entire fenced area.Further, depending on the width of the section, measure the distance between the future supports with a tape measure and also drive in the pegs there.

Then you can start fixing the base of the future fence. There are several options here:

- The first type of support creation is the priming of the pillars, to which the mesh sections will then be attached. It is considered the least time consuming and simplest.

- The second method is installation with preliminary concreting of the panel to which the post will be attached. When using the panel method, the possibility of misalignment of the support is excluded.

- The third method is installation on a solid solid concrete base. In this case, the likelihood of the fence skewing is also reduced to zero, and there is no need for a base plate.

After the concrete has hardened and the base is fixed, you can proceed to the final stage of installation - connecting the mesh panels to the support pillars. For fastening, special clamps are used, and in order to prevent moisture from getting inside the posts, which will contribute to the appearance of rust, plastic plugs are used.

Manufacturers, as a rule, attach installation instructions, and if you follow them, assembling a fence from a welded mesh will not cause difficulties and will not take much time.

Useful Tips

In order for the fence to be durable and reliably protect the property from unauthorized intrusion, you need to know some the rules that should be followed when choosing:

- Strength. Depending on the thickness of the metal rods from which the welded mesh is made, as well as on the internal size of the cells, its strength also changes. The thicker the rods and the smaller the cells, the more durable the product is considered.

- The size of the mesh fabric. This applies primarily to roll mesh. The dimension should be selected depending on how high the fence is needed. Manufacturers offer various options: 0.5 m, 1.7 m, 2 m and others.

- Cut or bend quality. The rods should be even, without flaws. This will affect the service life of the product.

- The shape and size of the cells, as well as the cross-section of the wire, must be identical to those stated in the documentation.

- The quality of the protective layer is also of great importance. The durability of the fence depends on its integrity.

- If the technology has been followed, then the welding will not damage the wire, and the welding place will be strong and reliable. If you purchase a roll mesh, you can check its strength by slightly unwinding the roll. If the welding does not crack, then you have a quality product in front of you.

- It is necessary to have a certificate of conformity or other documentation confirming the quality. The technical data sheet alone is not enough.

- All parts and fittings must be of high quality, and their quantity must correspond to that stated in the instructions.

How to choose?

The choice of a mesh fence depends, first of all, on where this structure will be installed. The price that the buyer will have to pay for the goods will also depend on this. It is ideal if, at a low cost, the products will also have good quality. There are many manufacturing firms in the modern construction market.

Each of them occupies a specific trading niche.

For example, buyers prefer to purchase domestic products for small areas because of their availability, but large customers often opt for more fashionable European products.

The most popular are several mesh manufacturers:

- Fensys... This is a Russian manufacturer, and its products are considered the most affordable. The firm produces panels using European technologies, but modifying and adapting them to the Russian climate. The mesh has a multilayer hot-dip galvanized protection. Wire diameter 4 mm. The color of the panels is standard green, however, if you wish, you can order painting in white, gray, blue, yellow.

- Grand Line. Another Russian manufacturer that produces 3D panels for fences. The wire thickness can be 3.5-6 mm, while the manufacturer gives a 10-year guarantee for the protective anti-corrosion layer. You can befit gates and wickets that are suitable for the design and installation technology.

- Gitter. The main production is located in St. Petersburg and the Leningrad region. The company specializes in the production of sectional structures, the price of which is low in comparison with European counterparts. The products are popular among summer residents and owners of small private houses.

- Fenci. The products of the Russian manufacturer are distinguished by their simple laconic design and operational reliability. The range of panels offered is quite diverse. The company produces welded nets of various sizes and costs, which allows you to choose fences for every taste and budget.

- Dirickx. It is a French manufacturer of mesh constructions. The diameter of the rods that make up the section is 4-5 mm. The anti-corrosion coating is applied by cold galvanic method, it has two layers: zinc and polymer.

For how to install a welded mesh fence, see the next video.

The comment was sent successfully.