How to choose a gate: characteristics of popular types

Swing gates are the most popular type of structures widely used in the arrangement of suburban areas, summer cottages, private territories. They are appreciated for their ease of installation, safety and reliability in operation. Modern manufacturers offer a wide range of swing structures, among which automatic models stand out. In this material, we will tell you how to choose a gate and give a description of popular types.

Peculiarities

Swing gates are distinguished by a simple, but reliable, time-tested metal structure. The advantage of these gates is the ability to pass vehicles of any height. Thanks to this, they have become very popular in places with an increased flow of large-sized vehicles, construction and agricultural equipment.

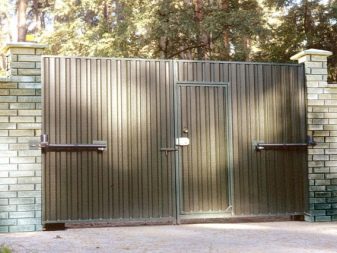

Beautiful street gates will be an excellent finishing element of the exterior of any country house, cottage, summer cottage. Forged, wooden, transparent or solid - the choice is yours!

Swing structures can be conditionally divided into two types: opening inward and outward.

By the type of control, they can be automatic and manual. Both options are suitable for operation on the site of a country house, while experts recommend giving preference to high-quality structures that will reliably protect your home and decorate your garden plot.

Designs with a wicket are very popular, the presence of which makes it possible to open the main sashes less often, especially if the product is equipped with an electric drive.

Such constructions, in turn, are divided into two types:

- the wicket is embedded in one of the gate leaves;

- the wicket is located next to the main door.

Both types have their own design features. The built-in wicket, fixed to the post with powerful hinges, saves space on the backyard. Therefore, such swing structures are often installed at the entrance to the garage. However, they have their own drawbacks - wickets are equipped with sills and restrictions from above, so it will be problematic to carry long and bulky objects through it. In addition, when entering, you will have to look under your feet so as not to stumble.

The second type of gate with wickets located separately is more convenient and practical, since they do not have fences and sills, and the width of the sash can be whatever. Such designs are more expensive, but more convenient to use.

Material

The material for the manufacture of swing gates can be different, it all depends on the architectural direction and design of the future structure.

The most common materials for creating universal swing gates are metal and wood. The characteristics of the finished product depend on the selected material: their strength and reliability. Consider the advantages and disadvantages of the main materials used for the manufacture of swing gates.

Pros of using corrugated board:

- has high strength, does not lend itself to external influences;

- differs in a low price;

- the texture of the canvas is uniform, so there is no need to select a pattern on the material;

- the material is easy to install, a conventional set of tools is enough to install the structure;

- the corrugated board is not afraid of moisture and is not subject to corrosion (rust can occur only as a result of damage to the protective layer of the material);

- a variety of shades allows you to choose an option for every taste;

- characterized by a long service life.

According to the manufacturer's data, corrugated structures can last up to 20 years.

The disadvantages include low resistance to mechanical damage, high windage and heating of the material under the influence of high temperatures.

The corrugated board is made by cold method from steel with galvanized or aluminum spraying. Polymeric materials are used as a decorative coating. The sheet thickness can be from 0.4 to 1 mm.

Pros and cons of wood:

- wood has a lower price;

- for the manufacture of swing structures made of wood, a standard set of tools is sufficient;

- the manufacturing process takes a little time (the only long stage is concrete hardening);

- the finished product has a pleasant design.

The disadvantages include a short service life, a low level of mechanical strength, and fire hazard.

Less popular, but no less reliable are swing structures made of a profile pipe. It can have several types of section: rectangular, round, square and oval. Durable carbon steel or galvanized steel is used for the manufacture of pipes. Stainless steel is considered to be lighter materials, therefore, gates made of this material cannot withstand heavy loads.

To create strong and reliable structures, a hot rolled pipe is perfect. They are a frame made of pipes and sashes, the design of which can be very diverse. Steel pipes are not inferior in strength. Using them, you can save on material consumption and reduce the cost of the entire product.

Solid metal sheets are more suitable for arranging garages. But for the fencing of large areas, blind wooden doors are used, made of oak, spruce, pine. Cloths made of corrugated board or polycarbonate are used for the manufacture of automatic structures, since they are produced in compact sheets, due to which it is possible to reduce the time for creating a product and reduce the amount of cutting.

For the manufacture of modern structures, combined options are usually used - wooden sashes with metal elements or, conversely, metal ones with forging.

Depending on the selected material, there are several types of swing structures:

- welded gates made of profiled sheet or professional pipes;

- PVC film gates;

- folding doors made of sandwich panels.

Constructions

There are three types of swing-type structures:

- with one sash;

- bivalve;

- with two leaves and a wicket.

Single leaf designs are less popular of all analog products and consist of one continuous web. Their lack of demand is due to the need to install additional powerful supports and a frame made of durable metal. In addition, more free space around them is required to open them.

Double-leaf structures are more common than others. They can be easily made and installed by hand. The design consists of two canvases of the same size, sheathed with sheet metal, the frame of the gate leaves, hinged posts, stoppers, latches, an electric drive mechanism, reinforced cylindrical hinges that can be adjusted. The pillars of the structure do not need additional reinforcement, and the free space is required half as much as for the previous type.

Gate with a leaf and a wicket - This is the best option for daily use. They are produced according to the principle of a two-leaf type, the only difference is that additional support is needed to enhance their strength.If the installation of the structure is carried out in the garage or in the opening of the industrial premises, then the opening of the wicket cuts into one sash and does not need additional support.

You should know: the gate can not always be made in the form of blind leaves made of metal sheets. Many designers decorate the exterior of summer cottages with more decorative gates with wrought iron elements.

The sandwich panel constructions are electrically driven sheets up to 45 mm thick, edged with an extruded aluminum profile. The top panel is covered with resistant enamel, which perfectly protects against minor scratches, temperature changes, humidity, and also has high anti-corrosion properties.

The advantage of using sandwich panels is that they can be installed in any exterior, regardless of the architectural features of the building.

In some cases, the installation of insulated swing structures is required, for example, in rooms where it is necessary to maintain a certain temperature. They are structures of two wings, supplemented with a safety rope on both sides. They can operate on an electric drive or manual control of the structure and have built-in or side wickets.

How to do it yourself

The design of swing gates can be made by hand if you already have experience in assembling such products. Since these products are not simple and are often supplied with automatic control, you just need to have the skills to work with a welding machine, drill, screwdriver, grinder, measuring instruments.

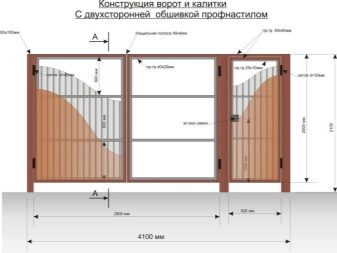

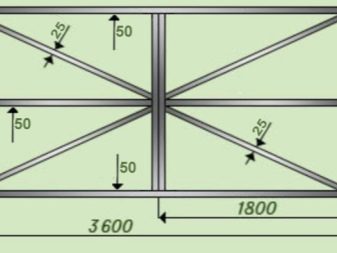

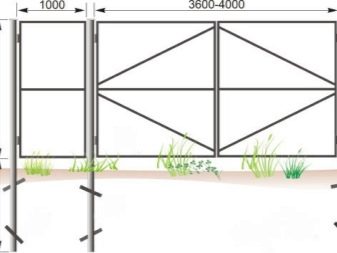

Consider a standard drawing of a swing structure.

As you can see, there is nothing complicated here, it is only important to know how to use the working tools correctly and correctly calculate the amount of required material. It is also important to make sure that all materials comply with the standards specified in GOST, and that the factory products are accompanied by a quality certificate, only then can we talk about the durability of the product.

Iron pipes are used as structural supports, which are built into columns or screw piles for greater reliability. For braces and crossbars, it is better to take a 20x30 or 20x40 mm profile.

The doors of the entrance gate must be screwed to the columns with self-tapping screws, you can also weld them onto the hinges. If you want to make a two-leaf structure, then a set of two hinges with a diameter of 20 or 30 mm is sufficient for one leaf.

The standard width of the entrance gate is three meters, however, it is best to select the optimal width of the moving leaf based on the individual parameters of a private plot. Remember that you can reduce the size by no more than 20 cm. The height of the canvas usually reaches 2 meters.

The locking mechanism is an L-shaped pin, which is mounted in the lower part of each sash. In the places of fixation of both flaps, holes from pipes are provided, with a diameter of about 5-10 mm. The thickness of the holes must not be greater than the thickness of the stopper. The length of the pipes is not limited, but experts do not recommend using pipes longer than 50 cm. If desired, the stopper can be supplemented with a horizontal gate, transverse along the line.

The decorative part is usually a lining with a profiled sheet, which is fixed at a distance of about 5-7 cm from the base.

If desired, even an electric drive (or actuator) for swing products can be made with your own hands. However, a beginner in the repair business cannot cope with this, since the creation and installation of a homemade actuator has its own nuances that are familiar only to professionals.

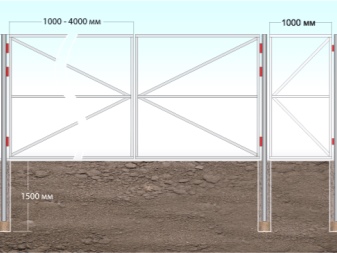

Mounting

The gate must be manufactured on a pre-leveled ground. The parameters of the finished structure must strictly correspond to the project drawings, therefore, all workpieces must be sawed with a tolerance of 1 mm.First, the details of the sash structure are welded, and then they begin to weld the crossbars and diagonals.

When starting the assembly, it is very important to correctly decompose the parts of the future structure, this will help to make sure that the parts are prepared correctly. Welding the elements takes a little time: first, the assembly is carried out, and then all the parts are welded to each other. The first is the door contour, to which the stiffeners will be attached.

Next, we proceed to welding the facing part, and only then hinges can be welded to the finished sashes. Layout for hinges and their welding is carried out at a distance of 30-40 cm from the edge of the frame. Bearings, clamps, sash wheels, locks and all other fittings necessary for the installation of a finished structure can be bought in a specialized store.

If the size of your design is non-standard, then you can order the production of parts according to individual parameters in a lathe.

The next stage of installation is the connection of the hinged post, which is also welded to the structure using the stick method. After making sure that all sizes are correct, you can proceed to the complete scalding of the hinges. If you wish, you can not use welding, but in this case, each canopy should be screwed onto self-tapping screws through thick steel.

Direct installation into the ground begins with the marking of the support pillars, which should be placed in the very center of the structure. As mentioned above, pipes must be installed in advance at the base of the pillars. They need to be dug into the ground to a depth of about 130-150 cm. This can be done using a drill, but do not forget to leave space in the pits for further pouring with concrete (about 10 cm is enough).

A layer of gravel is poured on the bottom of the pit under the columns and only then the supporting structures are lowered and poured with concrete. Further, support plates are welded to the posts, on which the hinges are subsequently welded.

It will take up to 4 days for the concrete to harden completely.

After waiting for the concrete to dry, you can proceed to the next stage: installing the hinged doors on the support pillars. The installation of automation can be carried out immediately after the structure is ready.

Having the skills in handling metal, if you wish, you can make homemade swing gates that will look no worse than factory models. High-quality materials and thoughtful installation will allow you to create a solid structure in a short time, and the presence of an electric drive in it will facilitate and modernize its use.

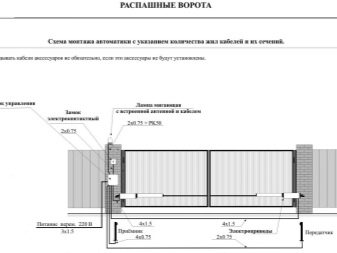

Choosing automation

Modern automation makes it possible to simplify the operation of swing structures and to open / close the canvas using a remote control. When purchasing ready-made automation, it is important to familiarize yourself with the rules of use and carefully follow the manufacturer's advice. Usually, the kit includes instructions for installing and connecting the drive.

Of course, you can save money and make an electric drive yourself, however, in this case, if the product breaks down, you will not be able to use the warranty service, and you will have to deal with troubleshooting yourself. There are several typical automation solutions on the market. All of them have a standard design consisting of a control unit, a signal lamp, an electromagnetic lock and a receiving antenna.

When choosing the optimal electric drive, it is necessary to proceed from specific parameters: the type of drive, power and the manufacturer. There are two types of mechanisms: linear and lever.

Consider the pros and cons of both designs:

- Linear drive. The system can be installed in any part of the doors and posts, and is suitable for very narrow posts. The advantages of using are the presence of a closer at the end of the stroke and a quick transition to manual control. Of the minuses - the limited opening radius of the gate, only 90 °.

- Lever drive. This mechanism is ideal for do-it-yourself installation and allows the sash to open 120 °.

The disadvantage of the product is the ability to mount only on wide pillars.

The automatic drive is suitable for installation on structures with both external and internal leaf opening. The control unit is usually installed on a post near the sash, leaving space for it in advance during installation. If the pillars are made of bricks, then even after installation, you can hollow out a niche in the right place. Also, do not forget that you need to think in advance about the place for the wiring.

When installing fire-prevention automatic swing gates, it is provided that the door leaf closes in the event of a fire. In the event of a fire, a signal is sent to the system sensor, and the electric drive automatically closes the gate, regardless of what position they are in.

Installing an automatic drive for the gate avoids the difficulty of opening and closing the leaves. Now it will be possible to control the shutters without even leaving the house: the remote control range can reach 30 m.

Manufacturers and reviews

The domestic market offers a large selection of gate automation from Russian and foreign manufacturers:

- Companies such as Came, Nice, FAAC (Italy), Baisheng (China), Marantec (Germany)... The Russian brand Doorhan is widely known in our country, however, Came and Nice are still the sales leaders.

- Chinese automation mainly designed to reduce the cost of products as much as possible to the detriment of quality, respectively, the durability and reliability of structures suffer. However, there are exceptions. For example, a Chinese corporation AN Motors offers excellent solutions for the automation of gate structures.

- From European manufacturers famous and popular for many years is an Italian brand Nice... He was one of the first to appear on the Russian market and managed to immediately establish himself as a bona fide manufacturer. Nice produces high-quality and reliable automation kits with an optimal price-performance ratio.

It should be noted that similar products from German manufacturers are much more expensive, however, the quality and performance are not much different from the products of other European companies.

When choosing automation, you should not save money, the poor quality of the electric drive will affect the functionality and durability of the entire structure.

Professional advice

When choosing a swing gate, you should know a few nuances that will allow you to choose the optimal design:

- Swing gates must be fixed in the open position, as the sash can strike in case of gusts of wind.

- In the presence of an automatic drive in winter, it is necessary to timely clear the snow on the path of movement of the shutters in order to avoid unnecessary load on them.

- If you plan to install automation, then it is better to give preference to lightweight material for the shutters - it can be corrugated board or polycarbonate.

- Wooden gates are distinguished by high aesthetic properties, but at the same time they are considered less durable. To enhance the durability of the structure, it is better to use solid wood, for example, oak.

- The best option for swing gates is a combination of a metal frame and wood-polymer leaves.

- Swing gates with wrought iron elements will add aristocracy and sophistication to the suburban area. The cost of such structures is much higher than the usual options from profiled sheet or sandwich panels.

- When installing swing structures, you should get rid of unevenness in the ground and other various elevations, otherwise the movement of the leaf flaps will be difficult.

- When choosing a wicket, it is better to give preference to separately located structures. Built-in wickets come with a sill, and when entering the site you will have to step over it.

- If you wish, you can equip the gate with a bell, an intercom, an intercom and even an electromagnetic lock. This is especially useful if the house is located far from the gate. You can operate the electromagnetic lock from a distance, and if you have an intercom, you can open the door without leaving your home.

There are many options for arranging swing gates. Each case is strictly individual and the creation of structures with your own hands can rightfully be called a creative process, because this is a unique opportunity to bring to life any, even the most creative ideas.

Swing gates will be an excellent protection for your private area, and the choice of high-quality ready-made structures will ensure successful operation for many years.

For information on how to choose automation for swing gates, see the next video.

The comment was sent successfully.