Lifting gates: how to do it yourself

The convenience of a garage for a car is not least determined by its entrance gate, which should ensure the safety of the car and close easily and reliably. Nowadays, you can order or make yourself several options for automatic designs. Next, we will consider how to make a garage door with your own hands.

Peculiarities

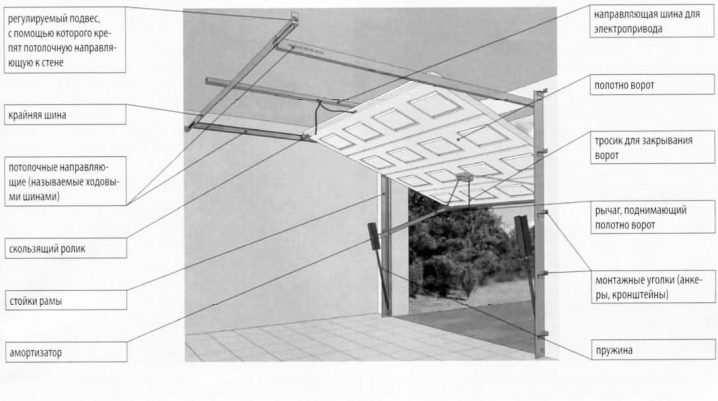

Unlike swing structures, which in most cases have 2 leaves that swing outward, lifting gates have sections or shutters that rise up. Their principle of operation is different depending on the type - sectional, swivel or roller shutter. The design itself, which includes various elements: a frame, guides, rollers, a lifting mechanism, is much more complicated than that of a simple swing gate.

But the costs of installation and materials fully compensate for the reliability and convenience with regular use of such a garage.

Having a ready-made garage with a rectangular entrance opening, you can easily build a lifting gate with your own hands. For installation, you will need a standard set of construction tools, materials for sashes, guides and body. It is enough to arm yourself with patience and turn on a little ingenuity in order to literally in a few days, without haste, build a reliable and convenient design of such a garage door.

Advantages and disadvantages

Before deciding to build a garage door with a lifting mechanism, you need to weigh all their pros and cons.

Experienced craftsmen note the following advantages of such systems:

- Saving free space. Unlike swing gates, which need external space for open sashes, overhead gates use the space inside the ceiling.

- It is much more convenient to use them, especially if they are equipped with a lifting mechanism, then no physical effort is required at all.

- Overhead and sectional doors reliably protect the garage from burglary.

- For such designs, you can use different types of finishes and decor.

- Lifting gates can be used for single and double garages.

- The doors open and close silently.

It is worth paying attention to the disadvantages of lifting gates:

- The main disadvantage is the complexity of the design and installation. If the installation is completely ordered by specialists, then it will be expensive. If you do the installation yourself, then you need to carefully study the drawings, fix all the elements carefully, under the level, because even a small error can lead to the fact that the entire mechanism will be inoperative.

- Fully open doors take up free space at the top of the opening and inside the garage under the ceiling.

- The mechanisms of such gates are designed for a certain load, therefore the sashes and the body cannot be overloaded, for example, when insulating.

- Lifting gates are only installed in a rectangular garage opening.

If the owner of the garage has taken into account all these features, then you can proceed with the installation. But first you need to decide on the type of garage door.

Views

The most common are 3 types of homemade lifting structures:

- lift-and-turn or panel board:

- sectional;

- roller shutters.

Up-and-over garage doors are the most burglary-proof thanks to the integral sash design. When opened, it rises up, turning 90 degrees and taking a horizontal position. Their mechanism can be lever-hinged or counterweight.The first view on the levers represents the simplest designs that provide a smooth and smooth movement of the sash to a horizontal position.

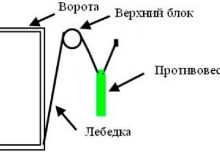

Counterbalanced gates are most suitable for heavy sash weights.

Lift-and-rotate structures consist of a frame (usually metal), guides along which the frame moves, a spring mechanism or a counterweight with a winch. Lifting can be done manually using the handle at the bottom of the body. This is done easily thanks to the stretched springs of the built-in mechanism. You can improve this mechanism by connecting an electric drive, then raising and lowering the sash is done by simply pressing a button.

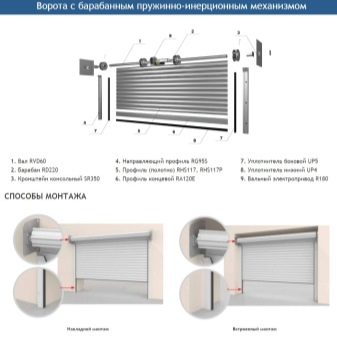

The overhead sectional door leaf is assembled from several panels up to 50 cm wide, which are interconnected by hinged hinges. When it is lifted, these panels (also called lamellas) move along guides on rollers. The movement is provided by a spring mechanism, drums and cables. This construction resembles a sandwich panel used in construction.

The mechanism of garage roller shutters is the same as that of roller shutters in shopping centers. Their folding slats are narrower than those of the lifting-sectional types; when opened, they rise and twist into a special box of small width. Therefore, this type has a clear advantage - saving space inside the garage. In this case, there is no need to mount long rails under the ceiling.

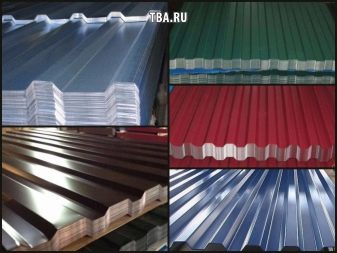

The materials for the frame, frame and guide rails of overhead gates are usually metal, but stainless steel is the best choice. The box can be made of thick wooden beams or metal corners. One-piece doors of this design can be made in the form of a sheet of boards in a metal frame. Outside, they are often sheathed with sheet metal.

To keep warm in the garage in winter, insulating materials can be sewn inside: sheet foam or mineral wool.

The box is covered with an anti-corrosion primer, then painted in 2 layers with alkyd or waterproof enamel. The hinged backboard is best covered with galvanized steel or aluminum.

Lamellas on sectional or roller shutter doors are usually also made of galvanized steel or aluminum; insulating material can be placed inside the sheets. The surface of such panels can be of any color - to the taste of the owner. Moving structural elements - rollers, couplings, are made of plastic or light metals, guides - from stainless steel or other materials that are not subject to corrosion.

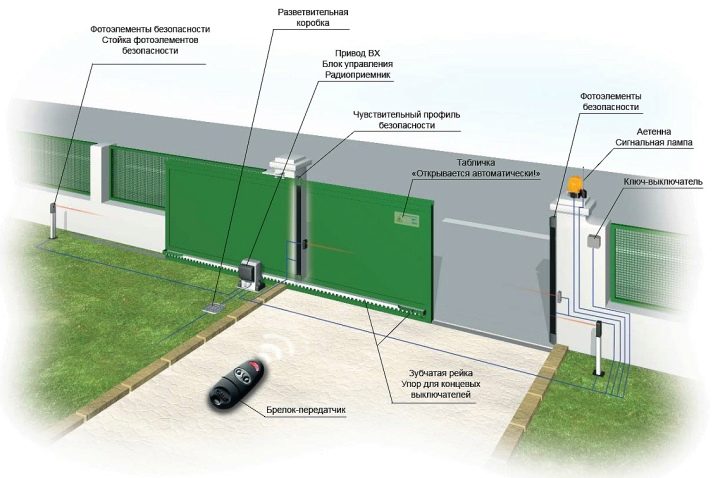

Automation of doors that open with the help of an electric drive will greatly simplify the use of the garage. Many drivers don't want to mess with heavy doors, especially when it's freezing or pouring rain outside. For any design and mechanism, it is possible to select an electric motor of the appropriate power, which will use the current from the household electrical network.

There are several types of automatic lifting gates.

The most common schemes that are easy to do yourself are:

- mechanisms installed on the door leaf;

- fixed on guides;

- mounted on side posts.

It is possible to order a ready-made structure, which will already include an automatic drive for lifting, such, for example, are equipped with many roller shutters with galvanized steel lamellas.

In this case, after the purchase, you just need to correctly install them on the garage opening and connect the electric drive to the network.

Manufacturing

For the manufacture of simple lifting garage doors, you can use ready-made sketches and calculations, only slightly adjusting their dimensions in accordance with your room. There are many examples of country house solutions containing blueprints and a detailed report including the necessary tools and materials.

Before making the structure itself with a movable mechanism, you need to make sure that the opening, adjacent walls and ceiling are able to withstand its weight. To do this, you need to choose strong and dense ceilings without voids and reliable fastening systems. And the room itself must be protected from moisture and other natural factors that can damage the operation of the gate.

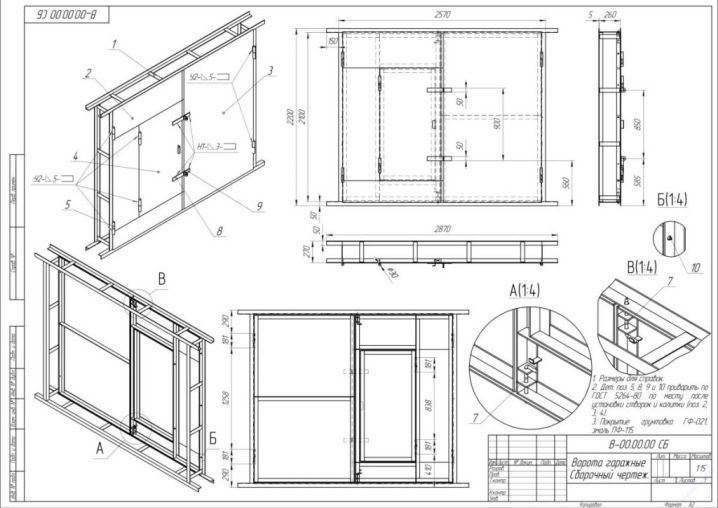

Having chosen a suitable type and an approximate project of future sliding gates, we make a drawing with exact dimensions, based on which we calculate the amount of materials required.

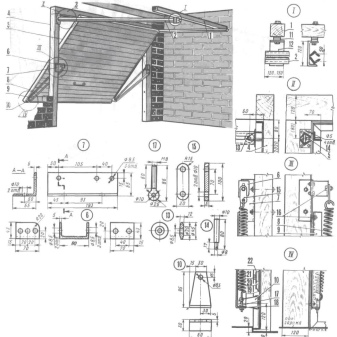

For a strong and durable frame of overhead garage doors, metal profiles 40x20 mm in size and at least 2 mm thick are most suitable. Transverse and horizontal fastenings for the structure can be made from 20x20 mm profiles. Gate guides are most often made of channels up to 20 cm wide, depending on which the size of the rollers is also chosen.

The lever-hinge box can be made from a metal corner or a bar. Parts of the required length are cut to the dimensions in the created drawing.

The rollers themselves, springs and the entire linkage mechanism are usually purchased ready-made. They are selected according to the dimensions of the guides. The rest of the parts can be easily made by yourself using a welding machine and a grinder.

For the manufacture of doors and their installation in the garage opening, you will need the following tools:

- welding machine;

- grinder with cut wheels for metal;

- drill with drills of the required diameter;

- screwdriver;

- hammer;

- level;

- tape measure, pencil.

For fastening, you need to use metal anchors or dowel screws suitable for the given weight of the structure. If you plan to use anchor bolts to fasten the metal corner, then you need to prepare a set of appropriate wrenches.

Mounting

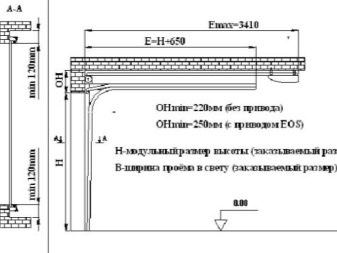

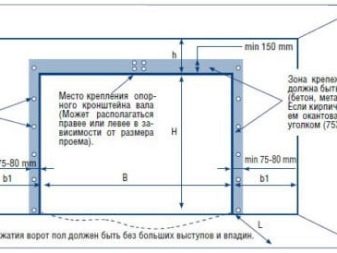

Before you install the lifting gate system yourself, you need to make sure that the opening on which they are installed has a perfectly flat surface: strictly vertical and horizontal level, right angles. The carrier box is the most important power element of such a gate, so you need to be as careful about its manufacture as possible.

If a metal corner is chosen for the box, then the width of its shelf should be 1.5 times the thickness of the sash. After all the parts are measured and cut off, they are attached to the garage opening with anchor bolts and tightened securely. For the manufacture of the box, you can also choose wooden beams with a cross-sectional size of 100x50 mm, which must be fixed on self-tapping screws 100 mm.

The one-piece swing gate frame must be assembled on a level, horizontal surface. After the metal profiles have been cut to the desired length, they are checked with a square and lightly tacked by welding. Next, check the right angles and dimensions again, including diagonally, attach the corner gussets and transverse stiffeners, then completely weld the structure.

After welding the frame, it must be cleaned with a grinder at the joints from burrs. Then it is covered with an anti-corrosion solution and painted. Boards with thermal insulation are sewn inside the metal profiles, outside it is covered with sheet metal. Brackets with movable rollers are attached to the upper corners of the frame.

After that, guides for the future sash are attached to the ceiling. They should also be mounted as evenly as possible, rechecking the horizontal level, parallelism and perpendicularity to the doorway. Then the sash is temporarily installed in the opening in order to mark the attachment point of the lever-spring mechanism.

After the operation of the gate has been checked and the unimpeded movement of the leaf along the guides, it is removed, the springs are mounted, and they are adjusted.Lastly, a rubber seal is attached to the frame around the perimeter to seal the seams and soft closure, a door lock and an opening handle are installed.

With careful and correct installation, as well as reliable protection from moisture, a gate with a similar design can serve for more than a dozen years. And their repair can be limited only by lubricating the moving parts of the mechanism, lever system, support rollers and replacing the rubber seal. For prophylaxis, lubrication can be carried out every season, and the outer rubber gasket can be lubricated with silicone before the onset of cold weather to protect it from freezing.

For the internal thermal insulation of such gates, you can use various materials that are also used for wall insulation: mineral wool, polystyrene or expanded polystyrene. The last two are more effective, since they do not shrink over time, but they can be fire hazardous, so it is better to choose non-combustible types.

Beautiful examples

There are a lot of beautiful projects for lifting gates, their designs allow you to make any kind of impressive design. Several good examples are worth considering.

Not only beautiful, but also a convenient example of a spacious garage for two cars, for each of which there is a separate entrance. The gate is equipped with a remote control for opening. Despite the fact that sliding roller shutters are only suitable for rectangular openings, here the architects showed their imagination and designed a figured arch.

A uniform color scheme for the exterior finish of the garage and the shutters of the lifting gates. Various materials can be used for cladding: coated sheet metal, plastic or plywood.

A simple but very stylish option for doors of different widths for two cars. Here shutters are used for the shutters, lightweight and taking up little space when folded.

Garage doors with wood finish in combination with the rest of the interior look very chic.

If the gate leaf is one-piece, then an impressive cladding can be made from the outside under an array of noble wood. High-quality panels look like a part of a medieval castle; it's hard to imagine that the mechanism is fully automatic.

A simple but nice option for roller shutters made of cheap materials. This is inexpensive and quick to install.

Light overhead gates built into the garden fence can replace a two-winged wicket door. With such a project, you can park a couple of cars on your suburban area and they will be reliably hidden from the roadway.

Watch the video for a master class on making a gate.

The comment was sent successfully.