Spray guns with tank

Spray guns made it possible to make painting easier and of better quality. In operation, special painting equipment is convenient, but it requires taking into account the design features. An important point is the location of the tank, which affects not only convenience, but also the final result of staining.

The device and principle of operation of the spray gun

Before moving on to the pros and cons of the various positions of the spray gun tank, it is worth familiarizing yourself with how it works, its principle of operation. The main component that allows you to spray paint substances is the air that comes from the receiver. It comes out of the blower, and then, moving along the hose, through the gap in the handle, it enters the spray bottle. After that, the air hits the flap, which moves aside when the trigger is pressed, and goes into the channels responsible for the supply of the painting material.

Dosing of the coloring matter takes place due to a metal rod, which has a cone-shaped tip. It is designed to fit snugly against the inside of the nozzle. If the tank is at the top, then the colorant is drained off due to the force of gravity.

The bottom tank on the gun uses the principle by which paint is drawn. In any position of the tank, the coloring composition moves into the nozzle, where air blows and, due to the pressure, comes out of the hole.

It is worth noting that the air enters not only into the passage with the painting material, but also on a special head, which helps to separate the solution into small parts. This is how atomization is carried out in a pneumatic apparatus. Spray guns are constantly being improved, their design changes, new materials are used, convenient functions are added. As a result, new models appear with interesting qualities. For different jobs, you should choose the best devices, since the final result of the staining depends on this.

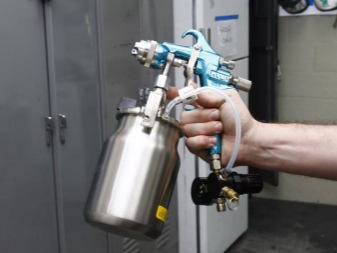

With bottom tank

A very common spray gun design that is widely used in certain areas. The device works according to the following principle: pressure drops in the container due to air flow over the tube. A strong pushing motion over the canister outlet displaces the paint and then diffuses from the nozzle. This phenomenon was discovered by the famous physicist John Venturi back in the 19th century.

The bottom-mounted tank on the spray gun is structured as follows: main container, lid and tube. These elements are interconnected by threads or lugs located on the lid. The tube is angled at an obtuse angle approximately in the center so that its end in the container can reach all parts of the bottom. This makes it possible to use the unit when tilting and paint horizontal surfaces on all sides.

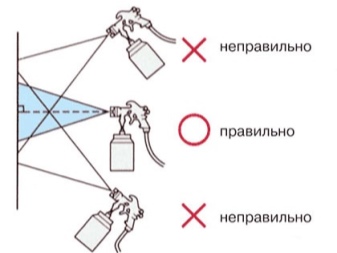

In such a spray gun, it is necessary to change the position of the tube, based on how the tool is located during operation. The tube should point straight ahead if the nozzle is downward, and if it is vertically upward, it should point backward. Most models with a bottom tank are made of metal and have an average capacity of one liter.

The advantage is that devices can be used for large-scale work. It is also convenient that the review remains open. The spray pattern with the tank at the bottom creates good coverage.However, such devices are considered not as professional as spray guns, in which the tank is installed at the top.

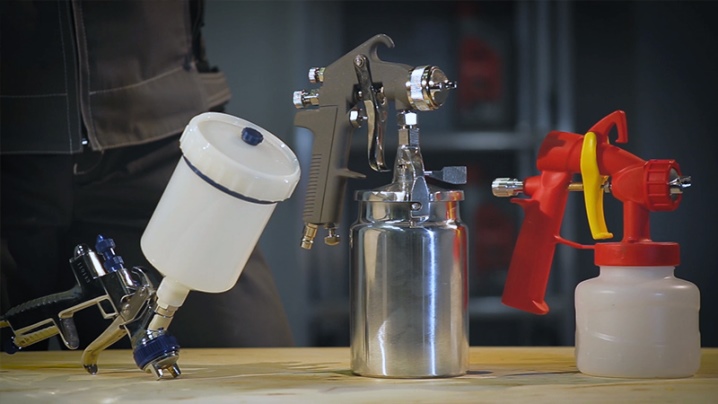

With top tank

The operation of such a unit is based on the principle of gravity, when the paint itself enters the supply channel. The tank is installed using a threaded connection (internal or external). Be sure to install a filter called "soldier" in this place.

In general, a spray gun with a top-down tank is the same as with a bottom tank. The main difference is in a container structure that includes a container, a lid, and an air passage when the volume of the painting material is reduced. The upper tanks are made of both metal and plastic. On average, the volume of such a container is designed for 600 milliliters.

With side tank

This type of spray gun appeared not very long ago, but it is quickly becoming popular. It should be noted that they are considered professional equipment... Quite often, such devices are also called adjustable and rotary. The paint solution enters the nozzle from the side by gravity.

For the manufacture of the side tank, metal is usually used. As for the connection to the body, it is carried out by means of a thread, which must be tightened by hand. There is a small hole in the paint container that allows air to flow during painting. The tank rotates 360 degrees, and its volume does not exceed 300 milliliters. This is because the paint does not touch the device even if tilts are made towards the nozzle.

What is the best location for the cistern?

To say unequivocally that a spray gun with an upper or lower location of the tank is better, it is impossible, since the difference between them is too significant. Each device has its own characteristics that must be taken into account in order to choose the appropriate option for a specific job. For example, models with a side cistern are light and compact and are best suited for painting cars or furniture. This is due to the fact that the tool can be used in any position, even with an upward direction.

When the tank is located at the bottom, it is convenient to process vertical surfaces, while the apparatus will be directed straight. Such devices are perfect for finishing work when you need to paint rooms, gates and fences, facades and other simple objects or surfaces.

Less often they are used in factories and in car services. An important advantage that the spray gun with a tank underneath can be put on something during operation, which allows you to rest or adjust if necessary. However, they must not be positioned at an angle so that air is not sucked in instead of the paint mixture.

Top-bowl models can be directed downward, upward and straight. Of course, you can tilt them without going beyond reason. The upper supply of the mixture makes it possible to use thicker mixtures for painting. Most often, spray guns, in which the tank is in the upper part, are used by professionals to work with cars, furniture and structures of varying complexity.

You can increase the convenience when working with a spray gun due to vacuum tanks... They can be placed on the top or bottom of the device. The design of the tank includes an outer plastic frame, an inner glass made of soft material, a mesh lid that acts as a filter. When spraying, the soft container is compressed, which makes it possible to use the device in any position.

Tanks of this type are designed as disposable, but practice has shown that they can be washed and then reused.

Tank making materials

The tank in the spray gun can be made of metal or plastic. The most popular are plastic tanks, which are less weight, transparent (you can track the paint level), suitable for acrylic and water-based compositions. The inexpensive cost of such containers allows you to change them when necessary.

The metal tank must be selected if there is a solvent in the base of the coloring material. The weight of such tanks is more, but in some cases you cannot do without them. Of the metals, durable aluminum is most often used, which is resistant to aggressive chemical components in paints. In addition, aluminum containers are easier to care for.

Operating tips

Before using the spray gun, it is important to check that there is no mechanical damage.... To do this, fill the tank three-fourths and start the compressor. Then check how well the bolts, nuts and regulators are tightened by connecting the gun to a hose with compressed air. If there are no malfunctions in the tool, and no mixture leaks have been identified, then the spray gun can be used as intended.

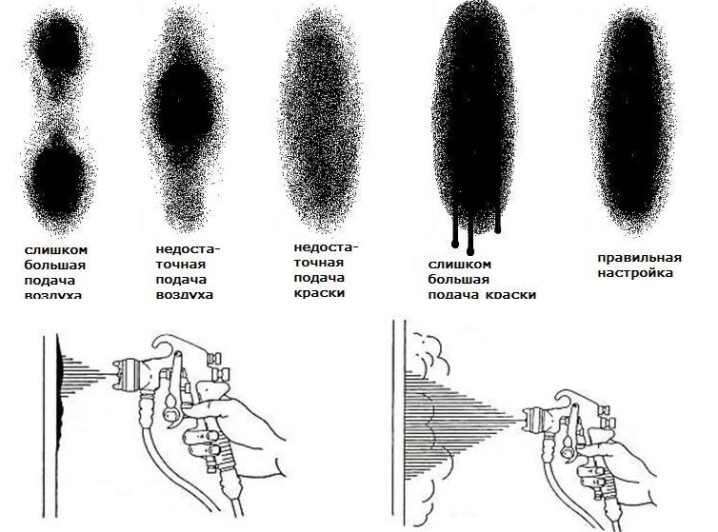

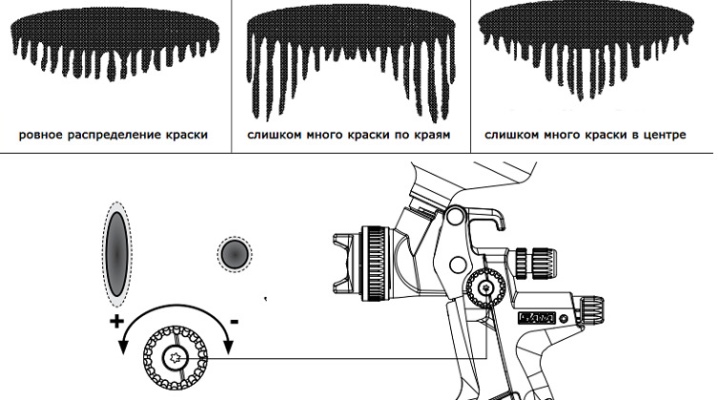

The parameters can be adjusted using the adjusting screws. For example, airflow is increased or decreased by rotating the screw at the bottom of the pistol grip. There is also a screw that allows you to adjust the flow of paint.

The shape of the torch is also selected by means of a special screw. If you turn it to the right, then the torch becomes round, and if to the left, then oval.

Correct use of the spray gun is impossible without observing a number of rules. So, when working indoors, you should take care of good ventilation. When painting outdoors, it is important to keep the unit in the shade and protect the work area from the wind. When painting a car, special care must be taken, as there will be a lot of easily explosive substances.

It is important to thin the paint before use according to the instructions in the instructions. You can check how optimal the consistency of the paint mixture is by the way the drop behaves. For example, if from a stick immersed in paint, it briskly slides back into the jar with a squelching sound, then everything is in order.

It is worth understanding that the drop should not stretch or fall quietly. In this case, more solvent should be added. The needle is responsible for the supply of paint, and it can be adjusted with a special screw. You should not open it to the full, as well as adjust the volume of the mixture by varying degrees of pressing the trigger. The size of the part directly affects the shape of the torch and is determined by the supply of air flow. For example, if the torch is made large and the air supply is small, then only spits will form on the surface, and not a uniform layer.

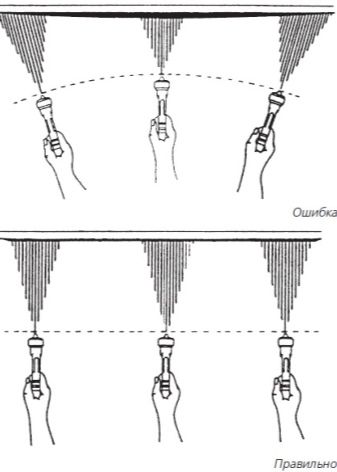

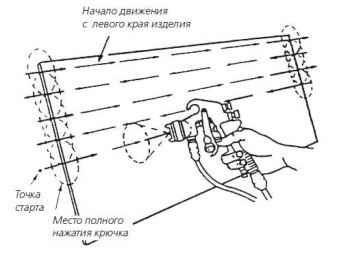

To understand how well the air is supplied, it is necessary to make test paints on separate sheets of Whatman paper attached to the wall. After preparing the spray gun for work, you need to make a control "shot" on the paper and examine the spot. It is desirable that it has the shape of an oval, elongated vertically, and the layer of paint lays down evenly. If droplets can be discerned, then add air, and if a distorted oval is obtained, then reduce.

At the end of the work with a paint sprayer, it should be well cleaned. To do this, the remaining paint must drain, and after pressing the trigger, you must wait until they merge into the tank. Then rinse all parts of the device using a solvent. It also needs to be poured into the tank, and then pull the trigger to clean the spray. In this case, the solvent is selected depending on the paint mixture. After rinsing with a solvent, all parts are cleaned with soap and water.

The air nozzle is cleaned from the inside using a knitting needle or toothpick. The last step is to apply the lubricant recommended by the manufacturer.

The comment was sent successfully.