Wood varnish: features of choice

Over time, each material loses its attractive appearance and shine. Painting is one of the main methods of updating the appearance of various materials. To return the wood to its former gloss and beauty, varnish is an excellent solution, which also gives the wood strength, perfectly protecting it from many external factors.

Peculiarities

Varnish is a viscous solution designed to treat the surface of a material in order to create a reliable protective film. The treated surface can acquire a light or intense gloss.

The lacquer coating was used for the first time in the 12th century by the German monk Theophilus. He strictly kept his recipe secret, only after many years in the course of research it was possible to find out that the varnish was created on the basis of alcohol. Since the 15th century, oil-based products have appeared. England is considered to be their homeland.

It was only in the 19th century that the manufacture of varnishes began in large quantities. Already in 1874, the production of excellent quality oil varnishes was launched at the Russian plant of Osovetsky. Later, other varieties appeared.

In most cases, varnish is used to cover wooden surfaces. Wood very quickly loses its strength and beauty when exposed to external factors, so the use of varnish allows you to increase the service life.

Types and characteristics

To date, a wide range of wood varnishes from well-known manufacturers is on sale. Depending on the type of application, they can be for internal or external use. They are characterized by varying degrees of gloss. But their main classification is carried out according to the type of solvent on the basis of which they are made.

Oil

Oil varnish is made on the basis of resin and oil, and these components are used in different proportions. Initially, resins of natural origin were used for their production, but then manufacturers switched to modified oils and artificial resins, which had a positive effect on the cost of the product.

All oil products can be divided into three groups, based on the amount of oil:

- skinny (35 to 55% oil);

- medium (from 55 to 65%);

- fatty (from 65 to 85%).

If we compare these varieties, then it is worth noting that skinny oil options dry quickly enough, but do not guarantee such reliable protection as oily type products.

The peculiarity of oil varnishes is their density. They are very difficult to apply with a brush, so you can thin the varnish a little before using it. After opening the container, the product will not be stored for a long time. Complete drying after application to the tree is carried out from about a day to three days.

The oil varnish penetrates very deeply into the surface of the wood. It can be used for interior work or to add strength and beauty to furniture. Experts do not recommend using this type for painting flooring.

Resin

These paints are made on the basis of natural resin, amber is often used. Some options are made from thermoplastic or thermosetting resin. They are synthetic. Resin varnishes are used for the same work as oil varnishes, they are an excellent alternative.

Alkyd

Such varnishes contain an alkyd resin (oil), an oil solvent and a desiccant, which helps to dry quickly. Since they include wood and linseed oils, they perfectly penetrate the wood surface and guarantee the creation of a high-quality and durable film. They are divided into two groups: pentaphthalic and glyphthalic.

These varnishes are characterized by resistance to sudden changes in temperature conditions., excellent moisture resistance. The service life after application is approximately two to three years. Complete drying of alkyd varnish is carried out in 48 hours. This species is in demand due to its low cost.

Among the disadvantages of alkyd varnish, it is worth noting its toxicity, because it contains white spirit. Also, the varnish is characterized by low wear resistance.

Alkyd varnish is used to cover wood parquet, floating floors and furniture. It enhances the beauty of natural wood, highlighting its texture. When working with this tool, craftsmen note that it does not flow into the cracks, and also does not glue the boards together.

Alcohol

This type of varnish is not very popular as it is very limited in use. They are also called polishes. They are made on the basis of resin and ethyl alcohol. This type dries very quickly, because the alcohol evaporates quickly. Complete drying is carried out in just one hour. Alcohol varnish gives wood an attractive shine, but its disadvantage is that it does not protect the wood surface from moisture. Affordable price is an indisputable advantage.

The polishes are usually used to treat various musical instruments., glass or leather products, occasionally they can be used to cover furniture products. Shellac varnish, which is a type of varnish, is widely used for decoupage.

Alkyd-urea

This variety consists not only of alkyd resin, but also includes amino-formaldehyde resins. The two-component agent can only be used after adding a hardener, which contains acid, because it is this substance that contributes to the rapid drying of the varnish. The resulting mixture should be immediately applied for painting, since the period of the prepared solution does not exceed several days.

This type is moisture resistant and durable, producing a high quality finish with a high gloss. It can be safely used for painting wooden parquet or floors made of wooden planks. It is often used to reliably protect solid wood furniture intended for indoor use.

Epoxy

The varnish is made on the basis of epoxy resin, which is a film former. This is a two-component option, as additional hardener must be used to dry. It is distinguished by high hardness, the formation of a strong film, is not afraid of mechanical stress, and is also characterized by moisture resistance.

This option is always chosen for wood that is exposed to heavy loads. It is ideal for covering solid floors or parquet, doors, both indoors and outdoors. After application, the product dries completely in 12 hours.

Polyester

This multi-component product is made on the basis of polyester resins. The application of varnish to the surface is carried out using a special pistol, so mostly professionals work with it. After drying, a heat-resistant, water-resistant film appears, characterized by strength and gloss.

Polyester agent ideal for treating musical instruments, flooring and wood furnishings.

Ethercellulose

This type of varnish contains cellulose nitrate, plasticizers, resins and an organic solvent.It is quick-drying, so it is a good solution for indoor work. The varnished wood surface can be polished because the film formed is strong and smooth.

Nitrocellulose cleaner allows you to create both matte and glossy surfaces. It is often used to paint furniture, but it is not recommended for flooring as the coating begins to flake off over time.

The disadvantages of the product include the presence of an unpleasant odor. And when the toxic solvents evaporate, then the smell disappears. Work with varnish is allowed only in a protective mask. The varnish is completely safe for human health after complete drying.

The ether cellulose agent is suitable for treating indoor walls, furniture, pencils and musical instruments, as it is medium strength and does not very effectively protect wood from sun and water.

Acrylic-urethane

This varnish is absolutely safe and odorless. It can be diluted with water. The product adheres perfectly to a wooden surface, guaranteeing a durable and high-quality film. The varnish can be used at an air temperature of at least 12 degrees Celsius. During storage, it allows a temperature regime of at least 5 degrees of frost.

Acrylic-urethane varnish is ideal for bathrooms, baths or saunas. It is often used to treat the sidewalls of floating parquet boards.

Alkyd urethane

Such a product consists of an alkyd resin and an organic solvent. It has a rather characteristic, unpleasant odor, but has a good service life.

Frost-resistant alkyd-urethane varnish is also called boat or yacht varnish, since it can be used for outdoor use, because it is highly resistant to various weather conditions. It is often used to handle ships.

Polyurethane

Polyurethane varnish can be composed of one or more components. Two-component versions have a base and a hardener, and three-component versions also have a solvent. This product is characterized by excellent adhesion and guarantees a hard coating. The resulting lash perfectly protects wood from corrosion, high humidity and chemicals.

The disadvantages of polyurethane varnish include a persistent and pungent odor.as well as a long hardening period, which usually ranges from two to three weeks.

It is often used to treat garden buildings, yachts and ships, parquet flooring, indoor and outdoor walls.

Acrylic

This varnish is water-based. It belongs to the safest and most environmentally friendly products for processing natural wood. The lack of smell allows it to be used even for the treatment of children's rooms. The disadvantage of water-soluble varnish is that it takes a long time to dry. Complete drying occurs after about half a month. First, the surface of the wood should be primed.

Water based acrylic varnish is fire resistant. It emphasizes the beauty of natural wood well, but does not provide the desired level of protection against moisture. Due to its fire retardant properties, this agent is suitable for finishing premises where there is a high possibility of fire. It can even be applied to wet wood, concrete and brick walls.

Bituminous

Bituminous varnish is ideal for wood processing, as it gives the surface optimal chemical and physical parameters. It must be applied to the wood in a very thin layer. Small wooden elements can be completely dipped in the product and then dried thoroughly. After treatment with bituminous varnish, wooden surfaces become resistant to both humid and acidic environments.

For aging the surface of natural wood, bituminous varnish is an excellent solution, because it can be used as a decorative one. The main pigment of the product is brown, so each surface after treatment acquires a pleasant shade.

Toning

A high-quality tinting varnish is indispensable for decoration or renovation work. It has a lot to do with wood stain. It can be applied to doors, furniture, wood flooring. It allows you to give wood an unrivaled appearance of valuable tree species, as well as gives it resistance to mechanical stress and prevents the formation of mold, blue stain, mildew or rot.

Food

These varnishes are suitable for treating wood surfaces that come in contact with food and drinks. It is absolutely harmless because it is made from environmentally friendly components. Food grade varnish can be used to extend the life of wooden utensils. It can be used to color cutting boards, cribs, toys, wooden sourdough or fermentation containers.

In a spray can

Varnishes in spray cans are in great demand among buyers, since they are characterized by convenience and simplicity when applied to a wooden surface. They have a substance that is inside the container under a certain pressure. The aerosol spray is fairly easy to spray.

Colors

Modern manufacturers of wood varnishes offer a wide range of colors, among which you can choose the best option for decorating the surface of natural wood.

Varnishes can be used to create a glossy or matte finish. Usually the manufacturer indicates this indicator on the packaging. Also, if you wish, you can purchase semi-gloss or semi-matt products. High gloss varnish provides an opportunity to give the wood a bright shine.

The most common option is transparent varnish. It emphasizes the wood pattern, gives it clarity and expressiveness. Tinting agents allow you to radically change the color of wood, therefore they are also called colored.

The most popular paints and varnishes are mahogany or walnut colors. White varnish looks original and impressive. It allows you to visually increase the volume of the product. Choosing a shade among dark colors, most acquire a black varnish. It adds sophistication and luxury to the surface.

Consumption

In order to correctly calculate how many cans of varnish are required to process a certain area, some calculations should be made.

First, you need to pay attention to the criteria that play an important role in spending funds:

- Wood surface. Wood with fine pores always requires less varnish than a surface with deep pores. For example, for processing beech or pine, the consumption will be much less than for dyeing ash or oak.

- The quality of wood polishing. There is always little varnish on a well-sanded surface. For high-quality sanding of the material, use sandpaper with a P100 grit. To create the second layer, sandpaper with P220 grit should be used.

- Viscosity. Thick varnish will be expensive. To slightly reduce it, the first and second application layers can be applied with a varnish diluted with a solvent. If the product is water based, then you can add a little water to make it thinner.

- Application method. If spray is used, then the consumption will be minimal. Using a brush or roller, the consumption of the product is significantly increased.

On average, varnish consumption per 1 m² is 100–125 ml. It will take less to create a second coat of varnish. So, for 1 m² only 80-100 ml are required. But the above factors play a decisive role, therefore, for an accurate calculation, you can purchase a can of varnish, use it and measure the area.This will make the calculation very accurate.

Manufacturers

Today many well-known companies offer a wide range of high quality wood varnishes.

Italian products are in great demand. Company Borma wachs has established itself as a high-quality and reliable manufacturer of products intended for processing natural wood.

Italian brand Sayerlack offers more than 3500 items, which fully meets the needs of woodworkers and furniture manufacturers.

Finnish company Tikkurila is a popular manufacturer of water-based varnishes for parquet flooring. It uses exclusively new technologies and computerized equipment to create high-quality and reliable products. The brand offers a wide range of wood varnishes that are characterized by increased wear resistance.

Swedish company Bona has been offering high quality water-based paints and varnishes for several decades, which do not have a characteristic odor. The brand has its own research center where innovative tools are developed.

This center has developed a unique varnish made of polyurethane particles Traffic... It allows you to give the coating increased wear resistance, as well as protect against mechanical stress, as a result, Traffic varnish is used to cover parquet in rooms with high traffic.

German brand Berger offers a wide range of water-based parquet varnishes of excellent quality. Berger Aqua-Seal polyurethane varnish is in great demand, which not only features increased wear resistance, but also protects wooden parquet from chemical attack. The only exceptions are nitro solvents, since they can damage the structure.

Italian company Vermeister is a renowned manufacturer of water-based polyurethane varnishes, which include two components and are designed to create a matte, semi-mat and semi-gloss surface. Aqua Play 2K varnish hardens in just four hours. The company offers products at affordable prices.

How to choose?

To choose the right varnish for natural wood, several factors should be taken into account:

- Terms of Use. The manufacturer indicates the operating conditions on the packaging. If it is necessary to paint wood on the street, then it is worthwhile to understand that the material is affected by ultraviolet light, high humidity, as well as a change in temperature regimes, therefore, it is necessary to use exclusively options for outdoor use. Indoor varnish is ideal for painting walls, floors and various objects.

- Wear resistance. It is worth paying attention to the load on the wood surface. For furniture, you can buy nitrocellulose varnish, which should be applied in a thin layer, it is not characterized by strength. To paint the floor, you need to take compounds that provide increased strength.

- Toxicity. Many modern varnishes contain organic solvents, which have a pungent and unpleasant odor. After the surface dries, the odor will disappear, but safety measures must be taken when working with it. If you need to do work at home, then the best solution is water-based varnishes, which are practically odorless.

- Complete drying time. Different versions have different drying times. It can vary from 5 hours to two weeks. The fastest dry are nitrocellulose and alcohol products, while oil varnishes and water based products dry longer than others. This characteristic plays an important role in order to correctly calculate the duration of the work.

- High temperature resistant. In places where there is a high risk of fire, only heat-resistant products must be used. It is necessary to pay attention to the technique of applying varnish, since it depends on safety.

- Shine. Varnishes can be matte and glossy. Their choice is usually made depending on personal preference, since they practically do not differ in performance. The matte surface attracts attention with the beauty of the wood, while the glossy surface visually makes it more voluminous. There are also semi-gloss and semi-gloss products on sale.

- Components. Varnishes can be composed of several or one component. The two-component options are used by professionals. The peculiarity of the two-component composition is that for the formation of a film, two substances enter into a chemical reaction. This film is characterized by strength and durability. One-component products can be used for personal needs, for example, if you need to process skirting boards or furniture.

- The need for a primer. This factor is very important, because if you do not prime the surface before applying varnish, then it will soon begin to flake off. Today, self-priming varnishes are already on sale, with which you can immediately cover wood.

For interior work

When choosing a varnish for interior work, you should look at the manufacturer's recommendations. A wall covering product can be of medium wear resistance, but this figure must be much higher to create a durable flooring.

Parquet floor or stairs can be varnisheddesigned for premises with high traffic. For processing wooden dishes, you can use exclusively food grade varnish, because it is non-toxic and safe for human health.

You should also pay attention to the smell of the product. Varnishes with an unpleasant, pungent odor can be used to paint surfaces only in non-residential premises, since until it dries, it can negatively affect human health.

For outdoor decoration

Only varnishes with high strength and wear resistance are suitable for covering wood in the open air. They protect the tree from ultraviolet radiation, changes in temperature regimes, withstand frost, and are also not afraid of high humidity.

For outdoor decoration, you can purchase products with a scent, since in the fresh air the effect of varnish on the human body is minimal.

For furniture

Manufacturers make separate varnishes for furniture from wood. They help not only to update the appearance, but also give the coating strength and reliability, and protect against mechanical and chemical influences. Depending on personal preference, you can choose the option matte or glossy. The matte table does not require any special maintenance, as it does not leave marks and streaks on it. A glossy finish is characterized by the presence of a shine, which must be maintained using special products designed for polishing furniture.

An important criterion is the environmental friendliness of the product. It is worth giving preference to water-based varnishes, since they are odorless and safe. Products with organic solvents can also be used, but the coloring process should be carried out with a mask or respirator to protect the respiratory system. It is worth remembering that varnish-and-paint products without organic solvents are fireproof.

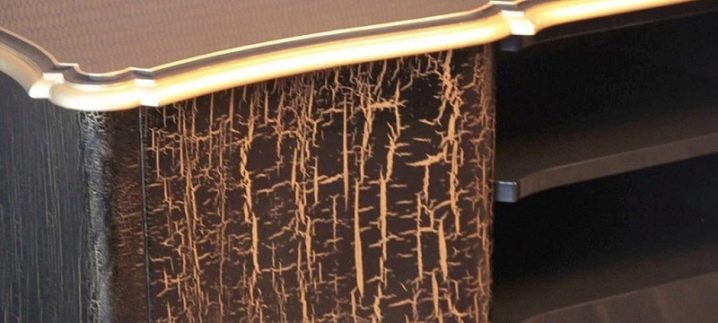

Craquelure varnish is suitable for giving furniture an antique look. The product dehydrates the paint, which contributes to the appearance of cracks. It should only be applied to dry wood surfaces. Paint should be applied over the not completely dried varnish.

The depth of the decorative effect depends on the degree of stickiness of the varnish-and-paint substance. Such decor should harmoniously fit into the interior design.

Helpful hints

To correctly apply varnish to a wooden surface, you should follow simple rules:

- The surface of natural wood must be sanded.

- If the wood is covered with varnish or paint, then these layers must be removed. You can use sandpaper or a special wash.

- All dust should be removed after sanding.

- Prime the surface. This will avoid the formation of bubbles and other visual defects.

- Apply varnish to the wooden surface.

There are several ways to varnish a wooden surface:

- The brush is ideal for handling small parts, as well as for applying the product in hard-to-reach places. To avoid streaks, it is worth using brushes that have "fluffing" at the tips of the villi.

- A roller is a good choice for large areas of varnish. When choosing a roller, it is worth giving preference to models with a pile of no more than 5 mm.

- Spraying is a convenient way of painting with a spray gun and a compressor. This option allows you not only to save varnish consumption, but also to quickly and easily process even hard-to-reach places.

Before use, the varnish should be thoroughly mixed, especially this rule should be followed if the product includes two components. This will have a positive effect on the durability of the coating.

If the varnish needs to be applied in several layers, then you need not only to wait until the previous layer has completely dried, but also to walk over the coating with sandpaper and remove all dust after that.

The number of layers depends on what is being processed. For example, two coats will be enough for painting furniture, while for flooring you will need to apply varnish three times.

In the next video, you will find a review of Kudo KU-904x tinting varnish for wood.

The comment was sent successfully.