Water-based acrylic varnish: features and benefits

Water-based acrylic varnish has appeared not so long ago, but at the same time it is becoming more and more popular among buyers. Polyacrylic paint and varnish material owes its popularity to a large number of advantages. This article discusses the features and advantages of such coatings, as well as the nuances of their use.

What it is?

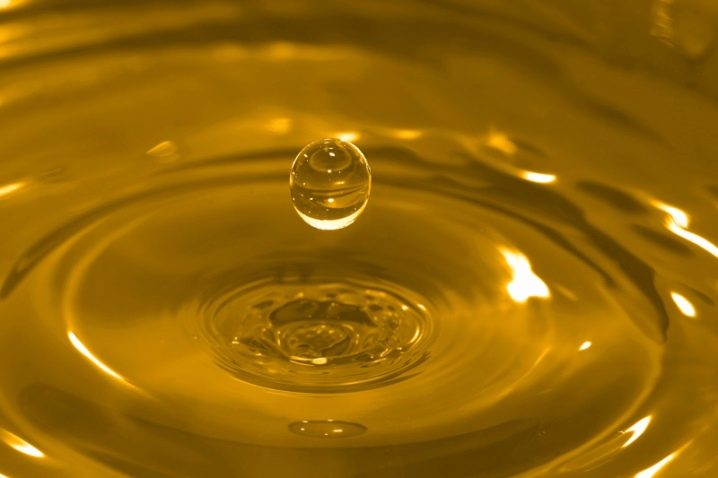

Manufacturers who create acrylic lacquer use the special properties of resins. Such paints and varnishes are made on the basis of a plastic dispersion completely dissolving in a liquid. After the varnish has hardened, the base is protected by a film characterized by increased strength. This coating is very resistant to various external influences.

Consumers quickly appreciated the unique properties of such paints and varnishes. They are used for a variety of purposes, for example, to create various adhesives and building mixtures.

Composition

A water-based acrylic lacquer is perfect if you want to accentuate the beautiful grain of the wood and protect it. Such paints and varnishes consist of different components.

In the production of such coatings, the following are used:

- plasticizer (it is this component that ensures the resistance of the coating to various mechanical influences);

- antiseptic;

- acrylic dispersion (liquid polymer).

Specifications

Such varnish is completely transparent, it has no color, its consistency is uniform. This material can dissolve in water, ether, ethanol, diethyl solution.

Physicochemical characteristics of such a material:

- the composition is viscous;

- does not have an unpleasant odor;

- the coating dries when the water evaporates, after which a shiny film appears on the base, characterized by colorlessness and transparency;

- the coating is very elastic;

When the paint and varnish material becomes completely dry, it loses its ability to dissolve in water;

- does not turn yellow over time when exposed to UV radiation;

- adheres well to substrates (in cases where there is no dust and dirt on the surface);

- dries quite quickly;

- completely ready for use;

- can be mixed with any dyes that dissolve in water;

- when applied, such varnish can be both pasty and liquid (the film will be elastic and durable in any case);

- when applying the material to the base, you can use not only standard tools (brushes, rollers), but also very convenient aerosols to use: materials in cans are sprayed on the bases as easily and quickly as possible, so today many people choose a spray;

- similar coatings can be applied to brick surfaces, stone bases;

- if necessary, such material can be diluted with water.

Main advantages

The advantages of acrylic varnish are many.

The most significant advantages for consumers can be identified:

- fire safety;

- aesthetics;

- antiseptic properties (the coating protects the base from the effects of microorganisms, mold);

- environmental friendliness, safety for human health;

- light weight;

- resistance to liquid, thermal conductivity;

- resistance to temperature changes.

Views

Acrylic varnishes differ from each other in composition.The material can be created on the basis of organic solvents or water-dispersion. The latter is more environmentally friendly, it is great for indoor repairs.

Similar materials are:

- two-component (polyurethane and acrylic - a group of substances that acts as a binder);

- one-component (only acrylic is the binder).

Such coatings also differ in appearance. The film can be:

- glossy (such a film is very shiny);

- matte (the coating makes the surface velvety);

- semi-matt.

Acrylic lacquer in any case very well emphasizes the natural beauty of the wooden surface, regardless of its type. There are pores in the wood, where this material penetrates.

Use in construction and repair

Since acrylic varnish is unique and versatile, it is very often used in construction and during repair work. Experts who know about the peculiarities of various paints and varnishes often choose not a paint, but a colorless varnish - such a coating can make the surface even more aesthetic.

Most often, these coatings are chosen in the construction of country houses and decorative wood finishing. In the first case, this coating does not change the color of the natural surface - it emphasizes its beauty. Acrylic varnish dries quickly, making it very suitable for outdoor use.

In the second case, such a varnish reliably protects the wood and looks great on such surfaces. It can be used on chairs, countertops, walls, sideboards, stools and so on.

Parquet floor varnish is quite popular.

Preparation of the base

If you want to spend as little material as possible and get the most even surface, apply a primer to the base before using the varnish. It is recommended to opt for a tinted impregnation or a special water-based primer.

For a "mirror-like" finish, wet the substrate with water and sand before using the primer. This method is called "wet grinding". For best results, sand each coat (except the finish coat) with a fine sandpaper.

When choosing a suitable coating, consider whether there are many irregularities on the basis. Gloss will only highlight all existing defects. If you want to hide them, opt for a matte varnish.

Acrylic varnish is quite suitable for renovating substrates that already have a layer of old paint on them. It will be necessary to pre-treat the surface with paint, using fine-grained sandpaper for this. Then you need to wash off the dirt with a soapy solution.

Application features

Remember that only water is suitable for thinning such materials. Do not mix acrylic varnish with drying oil, organic solvents. In order not to spoil the natural structure of the wooden surface, use 10% liquid for dilution, no more.

If the varnish is tinted and after opening the can you notice that the shades are different, do not worry - this is absolutely normal. To achieve uniformity, evenly distribute the tone, mix the material thoroughly before use.

When applying such materials, the humidity should not be too low. Otherwise, the coating will dry out too quickly and may develop imperfections. The surface should not be greasy.

When using tinted material, make sure that the layer thickness is the same everywhere. If in some place the coating is too thick, the shade will turn out to be quite dark. It is better to apply on the surface not one thick layer of varnish, but several thin ones. This will help you achieve maximum uniformity.

When applying the material to a surface that has an uneven color (which has already been painted before), you need to make sure that after applying a new topcoat, there is no more discontinuity. To avoid problems, clean off the old paint using sandpaper and apply a new paint composition to the cleaned wood. There is another way to hide the unevenness of the surface color: you can apply a darker varnish.

Before applying the tinted varnish, it is recommended to apply to the surface a material that has no color (another varnish or impregnation). This will improve the absorbency of the wood.

Famous manufacturers

Today, water-based acrylic varnishes are offered by a variety of manufacturers, but the most popular of them can be distinguished.

Many consumers prefer products Tikkurila... Materials from this manufacturer can be used for outdoor and indoor use. They effectively level surfaces, make them more aesthetic, provide reliable protection, and have antiseptic properties.

Varnishes from the company "Tex" are versatile. They are designed for decorative and protective functions.

Manufacturer Pinotex offers materials that are used for processing furniture items, skirting boards, doors, wooden dishes, walls, windows. They also protect the foundations and make them look very beautiful.

Products from the company "Lacra" can be used for external and internal work. Such varnishes make surfaces shiny, protect them from negative mechanical and atmospheric influences.

Materials from Eurotex suitable for chipboard, fiberboard, old and new surfaces made of wood, plywood. They provide protection of wooden bases from temperature extremes, precipitation, various microorganisms.

For flooring with water-based acrylic varnish, see the following video.

The comment was sent successfully.