Acrylic varnish for wood: types and applications

Acrylic varnish for wood is often used for interior work. Its inconvenience for external use is due to the specifics of the composition, however, there are still types for external decoration. The scope of use and features of this varnish should be considered in more detail.

Peculiarities

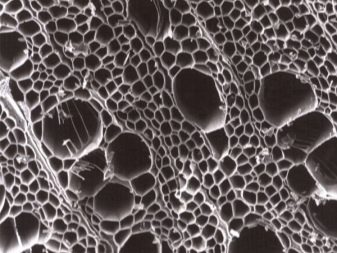

Acrylic lacquer contains dispersion and other substances that allow not only treating wood with a uniform layer, but also protecting it from some harmful effects. This refers not only to the consequences of the vital activity of microorganisms, but also all kinds of climatic influences: increased dryness or humidity, for example. By itself, such a varnish has the texture of thick sour cream, but it is more viscous. The classic color is delicate milky.

The tool has many advantages, including the following.

- Security. There are no toxic elements in the composition of acrylic varnishes. Some of them can even paint dishes.

- Durability. High-quality varnishes do not wear off much over time, reliably protecting wooden surfaces for many years.

- Ecological cleanliness. Not to say that all the elements that make up the varnish are natural, but it decomposes and at the same time does not harm the environment.

- Practical convenience. It is easy to care for varnished surfaces, especially if they have increased strength characteristics.

- High functionality. Varnishes are used for various coatings on wood, from painting tableware elements to finishing terraces and gazebos.

- Aesthetic appeal. Wood covered with acrylic paints and varnishes looks presentable. Its color and texture deepens, the texture appears more clearly

- Ergonomic This refers to the achievement of optimal performance with low material consumption. For example, applying only two layers, you can limit yourself to only them, since the tree will already look good.

- High elasticity. When solidified, the varnish forms a protective film, which cannot be removed in the future.

- High strength characteristics. Even at a high level of stress, the lacquer coating will never completely wear off.

- High adhesive properties. The varnish has good adhesion to the original surface, as a result of which such a high strength is achieved.

- Subtle smell. Many consumers note the presence of a faint smell, similar to that which is emitted by ordinary gouache. Epoxy and other paints and varnishes are in no way comparable.

- Short period of timerequired for setting and drying. As a rule, multiple coats can be applied within one daylight hours.

- Resistance to the vital activity of microorganisms. Acrylic varnishes clog the surface of the wood, preventing plant spores or bacteria from entering.

- Resistance to adverse climatic events. This also refers to the microclimate of the room. For example, lacquer material is able to protect wood from cracking in a room with dry warm air.

- Affordable cost. The price of acrylic paints and varnishes cannot be called excessively high, rather, it is at an average level.

- Ease of operation. Several tools are suitable for application at once: the varnish is not very capricious in this regard.

In addition to the advantages, the material also has some disadvantages.

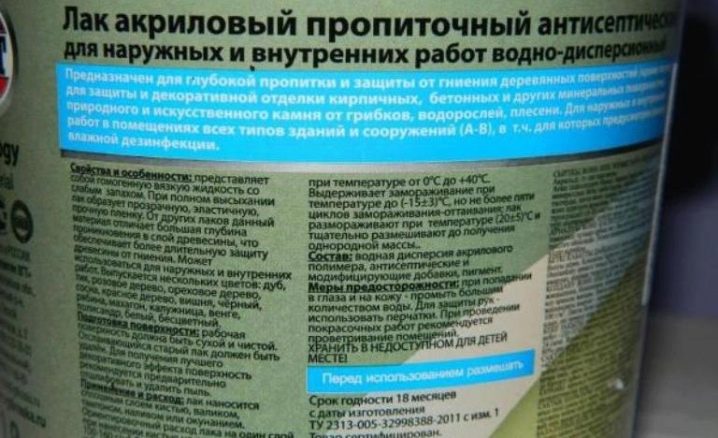

- The need for a special temperature and climatic conditions during application. Do not apply varnish if the temperature is below +5 degrees or above +30 degrees. The technology will be violated, and the paintwork will not be guaranteed to be durable. Drafts should also be avoided.

- The need for special storage. Do not freeze or even cool the material, expose it to sunlight.

Views

Initially, all acrylic varnishes are divided into two large groups: one-component and two-component. In one-component varieties, only acrylic is contained; two-component are also characterized by the presence of polyurethane.

It should be noted that two-component varnishes guarantee higher durability.therefore they are most often chosen for external work.

The most popular are water-based acrylic varnishes. They are increasingly replacing conventional furniture varnishes. Acrylic scuba diving has become so popular because compared to other products that are also water-based (alkyd, for example), they are cheaper.

The reverse side of the coin is strength characteristics. They cannot be called elevated. As a consequence, such varnishes are not used outdoors. They are suitable only for painting floors and furniture, while it is important to comply with all the requirements regarding the conditions for working with paint and varnish materials indicated on the packaging. Usually refers to temperature and humidity.

Two-component acrylic-polyurethane varieties, despite almost the same price, have higher strength properties than their one-component equivalent. However, you should not use this variety outside the room: it will not work for outdoor work.

Acrylate varnishes, also related to acrylic, have a slightly expanded area of application. So, with their help, you can not only tint and give a glossy shine to clean wooden surfaces, but also apply them to already painted elements. It is important to keep one thing in mind here. The paint used for painting must also be water-dispersion, otherwise the varnish will not set properly.

There are few types of acrylic varnishes, but each of them is universal. If necessary, you can use each of them for outdoor decoration, but only on the condition that you live in a temperate climatic zone without extreme weather conditions. Otherwise, the paint and varnish material will not withstand and will simply crack, having lost the lion's share of its operational properties.

Colors

Initially, acrylic varnish for wood is produced in a milky white color, but when it dries, it forms a colorless film that only emphasizes the texture of the wood without giving it any special shade. The transparent film only adds shine, due to which the original tone of the wood appears deeper and richer.

In recent years, new production and tinting technologies have appeared, which have significantly expanded the color range of varnishes. Now you can easily purchase a tinted acrylic sample, which can successfully replace the stain. So you can solve two problems at once, without resorting to complicated procedures: to give the boards the desired color and to protect them.

According to the level of gloss, five degrees are distinguished, each of which is characterized by the amount of light reflected in percentage by the surface covered with such varnish:

- high gloss - more than 90%;

- glossy - 80-90%;

- semi-glossy - 40-50%;

- semi-matte - 10-15%;

- matte - less than 10%.

When choosing, it is worth keeping in mind the features of shiny coatings. On glossy surfaces, all the flaws stand out strongly. Moreover, it is more often used to decorate modern interiors in hi-tech, futurism and the like.Matte varnish, on the contrary, allows you to partially hide blemishes, and the surface is velvety. Such an effect is needed when creating an atmosphere of coziness, for example, in the styles of Provence, country and others.

When choosing a varnish, decide what effect you want to achieve in the end. You may just need to emphasize the beauty of the wood or slightly change its shade, give the wood a shine or pearl shine. Remember that if you don’t like the way this or that varnish lays down, you can partially dismantle the acrylic film by “walking” over the surface with a grinder with a special grinding disc. However, care must be taken to ensure that the removal is the same throughout the entire area.

Famous manufacturers and reviews

Currently, several companies occupy leading positions in the quality of the varnish produced. Among them are Russian, Finnish, Slovenian manufacturers. Below is a list of those that users gave only positive reviews.

Tikkurila

Finnish products are striking not only for their excellent quality, but also for their price. It is 3-4 times higher for other similar products from other brands. However, acrylic paints and varnishes are the safest and most reliable of all.

"Chief Technologist"

This acrylic-based latex varnish is designed to accentuate the texture and color of wood, and at the same time protect it from negative environmental factors. There are also toning options for unusual shades, for example, "Lemon" or "Spruce Green". "Drevolak". Wax is added to the products of this brand, as a result of which the fat content of the composition increases and, consequently, its protective properties. It is better to use "Drevolak" for internal work, outside it will need to be applied in 3-4 layers.

Vika

The company is engaged in the production of two-component paints and varnishes, which are distinguished by a high solidification rate, as well as increased strength characteristics, especially if enamel is applied under the lacquer layer.

VGT

Such varnishes should not be used on floors. Initially, the composition has a milky white color, but upon drying it becomes completely transparent, so that its presence has practically no effect on the original shade of the wood.

Belinka

This Slovenian company offers some of the finest acrylic varnishes. Their safety both for humans and for the environment is confirmed by many certificates.

Kudo

Produces varnishes in handy sprays. There are tint products, which means that tinting is not needed - you can choose the desired shade from a wide range of colors.

Eurotex

This acrylic sample belongs to aqualak and looks more like impregnation than varnish in the classical sense. It reliably protects wood from negative influences, microorganisms and abrasion.

"Pinotex"

The safest product on offer and can also be used to coat wooden utensils. These varnishes cannot be used for external work, since they play a more decorative role.

"Lacra"

Offers excellent varnishes that perfectly protect against negative influences. Suitable for both indoor and outdoor use. The quality of the goods is at the highest level.

Selection and application

Acrylic varnish is applied in several layers.

Several tools can be used for application:

- Roller with pile length up to 5 mm. Ensures fast staining.

- Brush. The work is more laborious, but it is possible to decorate all hard-to-reach places.

- Spray gun or spray. The most convenient and economical application method. Allows you to apply an even layer, even on hard-to-reach places.

The choice of this or that material is half the battle. Make no mistake. So, if you plan to cover, for example, a chest of drawers with an abundance of carved parts, then it is best to use a spray gun. A roller is also suitable for even plank floors.

Before starting work, you need to complete the preparation. The surface must be cleaned, in some cases a primer is needed. If possible, refuse to purchase an acrylic sample that is superimposed on a primer. Then the original texture of the wood will be pronounced.

Few varnish can guarantee a protective finish after one coat, so they are applied in at least two. To make the coating even, you need to sand the first layer after it dries. After cleaning the surface, you can apply a second layer.

After all the work on applying the varnish layer is completed and the coating has dried out, you can proceed to finishing. Keep in mind that acrylic varnish dries completely in two days. For this, it is best to use parquet care products or wood wax. Such procedures will save the varnish coating from quick deterioration, because it will pick up its final performance characteristics only after two weeks.

Advice

Finishing professionals share some recommendations regarding the choice of acrylic lacquer, its use, operation and storage.

- It so happens that the varnish thickens over time, and it needs to be diluted. Under no circumstances should solvents or other chemicals be used for these purposes. Only clean water will do.

- When diluting, you need to remember the proportions. If you add more than a tenth of water to the composition, this will lead to its loss of properties and rapid deterioration of the wood after processing.

- Before using the paint and varnish material, it must be thoroughly stirred in order to exclude the possibility of streaks and color spots on the surface.

- Before processing, you need to check the moisture content of the wood. Ideally, it should be well dried, but it is permissible to varnish the boards if their moisture content does not exceed 50%.

- Degrease the surface thoroughly. In places with greasy stains, the varnish simply does not adhere to the surface, and this will lead to defects. In addition, when a milky substance is applied to such places, its color will not disappear, but will remain the same, which will be very noticeable.

- Follow the instructions. It will probably say there that you do not need to make one thick layer of material. It is best to overlay a pair of thin ones.

The intricacies of applying acrylic varnish to wood are described in detail in the video.

The comment was sent successfully.