What is quartz vinyl and what is it like?

Quartz vinyl can be considered a conventional newcomer to the building materials market. It appeared not so long ago, but has already gained popularity as an excellent product for wall and floor decoration. The aesthetic indicators of the material are highly rated, and the ease of installation attracts with its availability.

What it is?

A new topic of discussion, quartz vinyl, has become known primarily as a flooring material. Externally, quartz vinyl dies are difficult to distinguish from traditional wood-patterned cellulose lamellae. But to say that quartz-vinyl is the same as laminate is impossible. Yet again, if you take a fragment of it in your hands, it will be clear that it is rather plastic, albeit of high quality. It looks like wood, like marble and like stone, it is an imitation material.

Quartz vinyl is most often referred to in the context of tiles. It is considered an advanced PVC panel technology. The modern material optimally copies the texture of the imitation material, it is more reliable than the PVC panel, because it contains a natural ingredient - quartz sand. Hence the name: quartz - quartz sand, vinyl - polyvinyl chloride (PVC).

Sometimes this material is also called liquid parquet.

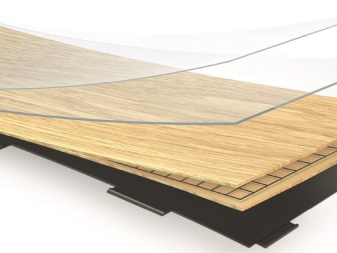

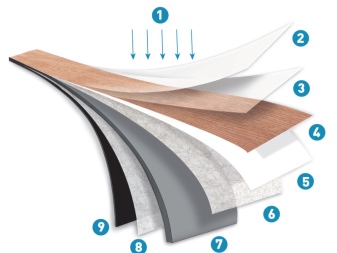

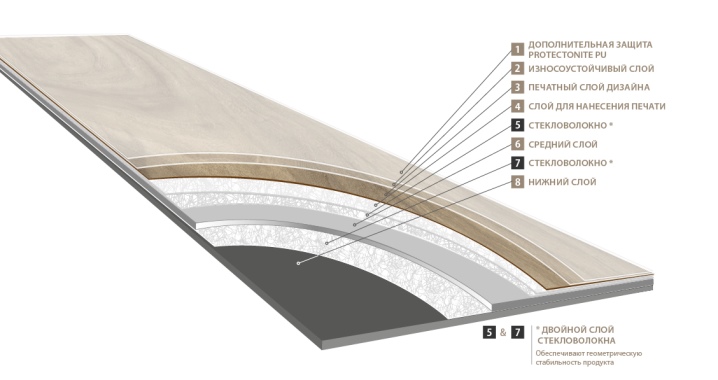

In structure, it is a multi-layered "pie" consisting of:

- base layer - PVC, which adheres perfectly to the base of the floor;

- fiberglass - it is needed to reinforce the frame;

- quartz layer - necessary for strength and thermal insulation;

- decorative layer - creating texture with a pattern;

- polyurethane with aluminum oxide - a protective coating that prevents the destruction of the material under mechanical action.

Molecular plasticizers, pigments to create the desired color, stabilizers and lubricants can also be included in the composition. The main share of high-quality quartz-vinyl should be quartz sand. If this figure is in the region of 80%, the product will be a profitable purchase. The percentage of sand can be higher.

And although the tiles or dies include so many layers, they themselves are thin, about 5 mm. Finishing material is made by soldering and pressing methods. For the consumer, the variability of the shape of the material is beneficial: either the usual boards / panels resembling a laminate, or tiles. Not all finishing products have such a choice, and it is this characteristic that often becomes the main reason in the search for the desired finish.

Advantages and disadvantages

In advertising, you can often hear that the material is environmentally friendly, and environmental friendliness is the main advantage. But there is some slyness here. Quartz is a natural ingredient, but not the only one. PVC is the second main element in the structure of the material and is present in sufficient quantities not to consider quartz-vinyl an absolute eco-product. Although the high content of sand, of course, pleases the consumer.

Material pluses:

- versatility - even on the floor, even on the walls, it will look great both there and there;

- moisture resistance - this allows you to use quartz-vinyl tiles or panels in the kitchen and bathroom;

- resistance to temperature shocks - the material will not change shape, will not create cracks even with strong heating;

- ease of cleaning - you will not need to treat quartz-vinyl as reverently as to laminate;

- not afraid of burnout - which means that over time the material will not fade;

- heat capacity - not to compare with ceramic tiles, it is cold for feet, but quartz-vinyl tiles are pleasant and warm;

- the possibility of repair - if one board or tile is out of order, it can be replaced without dismantling the entire coating;

- ease of installation - you can handle it yourself, without attracting additional labor.

It seems that such advantages are already enough for a convincing choice. But there are always disadvantages that you can't go against (though they may not be so significant).

Cons of material:

- before laying, the surface needs to be leveled, that is, there is a need for preliminary repair work;

- good elasticity also results in the fact that bumps and other unevenness of the base can appear under the tiles or panels.

All other disadvantages are relative. Not a 100% eco-friendly material, so it doesn't pretend to be in this niche. There is not enough variety in design - as anyone, many are lost in the choice precisely because of the great variability. Expensive - well, not at all as expensive as parquet, quite an affordable option.

How is it different from vinyl?

Everything is simple and obvious here: the base layer of the vinyl floor consists of half of polyvinyl chloride, and the same layer of quartz-vinyl floor is made of quartz sand and shell rock, and PVC is used as a bond. That is, quartz-vinyl contains at least 40% natural components (or even 80%), which is a major difference. Simply put, quartz vinyl is better than plain vinyl by the presence of a large amount of a natural component in the composition.

This automatically makes it the preferred material.

Quartz sand and shell rock in the formula of a finishing product change its technical characteristics. Such a floor, for example, will be less compressed. In addition, sand is also a reinforcing component. For example, if there are table legs on such a floor, they will damage it less than if the floor was just vinyl. This is a more durable material, which means that the next repair will not be soon.

And the addition of quartz sand makes the material fireproof. The flame, if it occurs, will not spread further, but will go out. It will go out because it reaches this sandy layer. But the vinyl panel in the same situation will predictably melt to the ground. For this reason, quartz vinyl is preferred in high fire hazard areas: conference rooms, corridors, etc.

In fact, any material has to change its linear dimensions to one degree or another under the influence of temperature. A quartz vinyl floor has less linear expansion than a vinyl floor. And this is important when it comes to rooms with large areas, as well as for spaces with panoramic windows, where there is a lot of natural light. That is, quartz-vinyl is less likely to "bulge", the sand helps to keep the shape of the plank or tile.

And in this he again outperforms conventional PVC panels.

Finally, not the least important is the question of aesthetics. Walking on the floor, which contains quartz sand and the same shell rock, is more pleasant. If the material is used for wall decoration, they will even look (and even more tactile) more pleasant. Vinyl has an external artificiality and gives itself out to the touch. And vinyl has only one obvious advantage - it costs less.

Types by connection type

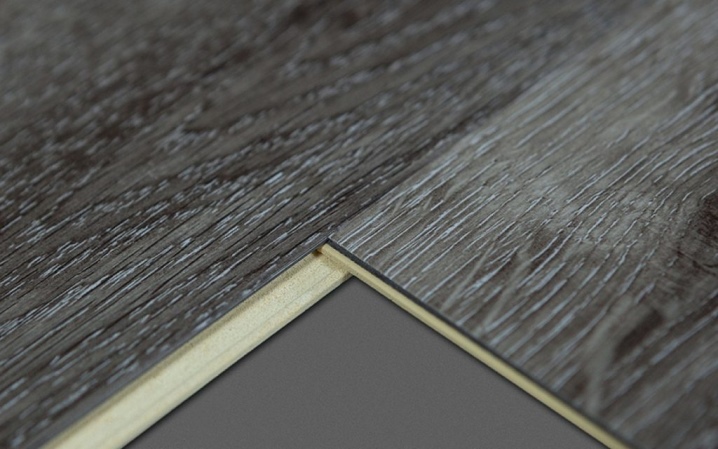

Elements can be fastened in two ways - by locking and adhesive.

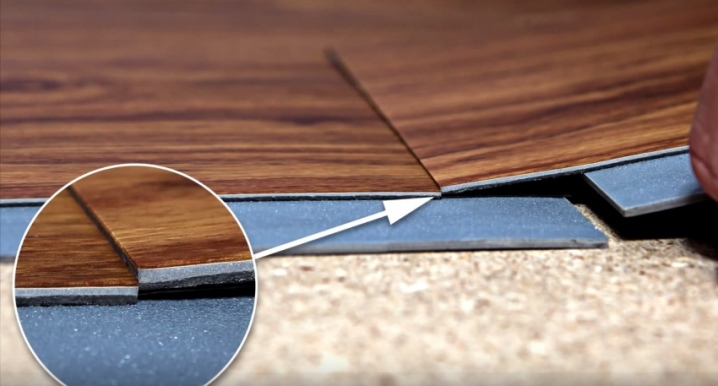

With a castle

It is easy to assemble such a floor or finishing wall covering of the walls, you can compare it with the principle of folding a puzzle. But at the same time, the floors and walls must be perfectly flat, otherwise everything will go down the drain.

Why this option is good:

- any failed section can be dismantled and a new one inserted;

- the material can be combined with the underfloor heating system;

- a coating is formed that gives the feeling of a warm and soft floor;

- outwardly perceived as a monolithic single coating, without clearly visible individual components - for many, this argument dominates;

- the modules are stacked as you like, the stacking angle is also variable, that is, you can think of a design method of stacking that will look very original.

If we talk about the shortcomings, then everything will have to return to the same absolute: only a perfect flat base under quartz-vinyl, no indulgences. Installation will consist of base preparation, tiling and quality control of the work. The two modules can be fixed with a rubber mallet. The modules should fit as closely as possible to each other so that no gaps are formed.

With glue

Adhesive quartz-vinyl involves fixing each fragment on the floor or wall with a special adhesive.

But here, too, there are options:

- glue tiles - that is, each element is fixed with glue, the base, again, should be even;

- self-adhesive lamellas - the reverse side is already covered with glue, protected by a special film that is removed during installation;

- decorative panels or tiles with adhesive interlock - such a covering can even be laid on an old floor.

Someone will say that gluing is obviously easier, but not everything is so simple. Repair of such a floor, in the event of damage to one of the fragments, will not be as simple as in the case of a lock connection.

Application

Quartz-vinyl may be installed on the ceiling, but these cases are, rather, exceptions. And the floor and walls are ennobled with it much more often. Such wall finishes are usually found if you want to highlight some area in space. For example, in the living room, mark the media zone: you can simply combine the wallpaper, or you can do it radically.

It looks very interesting.

The kitchen apron is also laid out with quartz-vinyl, given that the material is moisture resistant, it is possible. The floors on the balcony, in the corridor, in the bathroom, in the kitchen also change if they are finished with quartz-vinyl. And it is also used if you need to update the tabletop of an old table - it can turn out very nice.

Dimensions (edit)

The length of one fragment varies from 30 cm to 120 cm, while the standard length is hidden in the range of 30-60 cm, and this is most often a rectangular tile. And here slabs that are longer than 90 cm are more logically called strips (by analogy with laminate).

The width of a fragment of a quartz-vinyl finish is 20-60 cm, there are even tiles a meter wide, and they are convenient for organizing repairs in premises with a significant footage.

Tile thickness - 2-5 mm. The strength of the product, the number of layers that exist in this finishing "cake", the weight of the material and, of course, its flexibility will depend on the thickness. For example, very thin fragments, less than 3 mm in thickness, are used only for adhesive fixation.

The most demanded size of quartz-vinyl tiles is square shape - 30 by 30 cm, and rectangular - 30 by 60 cm.You can also find triangular fragments that create an interesting design in decoration.

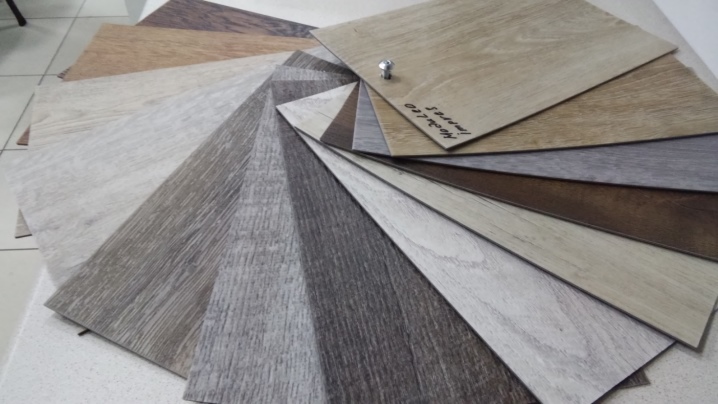

Design

Here, the charm of the material is revealed to the maximum. Firstly, the choice of textures and colors is wide, and you can find any option with an exact imitation of marble, stone, concrete, wood. Once upon a time, everyone tried to take wood trim, but today, even in small apartments, imitation of stone and concrete is increasingly appearing, which was facilitated by modern interior styles.

Quartz-vinyl meets current needs, therefore, not only gray, white and beige colors of the material can be found in the building market.

How to install is also important: "herringbone" or "French tree", for example, are very popular solutions. By the way, this is a very interesting comparison. An ordinary "herringbone" (otherwise it is also called English) is created like this: the planks are located at right angles to each other. One-row, two-row and even three-row English herringbone can be made.But the "French tree" requires joining the planks not perpendicularly, but using an angle of 30 or 60 degrees (or intermediate values of these numbers). Laying with rhombuses, rays, ferns - these are all variants of the "French Christmas tree".

Manufacturers

Each sector will have its own winners. After all, quartz-vinyl can be of different wear resistance, but mostly brands of all categories are heard.

This list will definitely include:

- Alpine floor - German brand with affordable prices and a wide range;

- Art east - made in Russia, tiles that collect very good reviews;

- Refloor fargo - another Russian company that can boast of high sales volumes;

- "Decoria Rus" - a well-known importer of Korean quartz-vinyl to the Russian market, it will be difficult to choose the right tile, because the assortment is simply impressive;

- "Vinyl" - premium quality with a twenty-year guarantee;

- Pergo - made in Belgium with a natural design and the most natural texture.

After the purchase, the most crucial moment begins - installation. None of its stages will tolerate mistakes.

Installation tips

Work begins with leveling the base. The floor must be solid and stable, otherwise all other actions are meaningless. You can fix quartz-vinyl on a wooden surface - on the same plywood sheets, on moisture-resistant chipboard and OSB, which must be covered with a primer. The prepared base should be checked for moisture, if the indicator is higher than 5%, this is bad. Additional drying may be required.

The subsequent stages of work must also be taken into account.

- Markup. Through the midpoints, you need to draw two lines perpendicular to each other (they should also be parallel to the walls). As a result, a grid of four equivalent rectangles should be formed.

- Laying tiles with a lock. The decorative element is laid with the grooved side against the wall. In the first row, the grooves must be cut, the tiles must be tightly moved to the vertical plane. The ends of adjacent products are connected. The next row is mounted with closing the connections of the decorative elements.

- Laying lamellas with glue locks. It is also necessary to lay from the corner, the new tile, creating a certain slope, will be aligned with the side of the already mounted fragment, then it goes down and squeezes. The next rows can be laid out without offset or offset by 1⁄2 or a third of the tiles.

- Installation with glue. It is carried out from a central point, the glue must be either special quartz-vinyl or dispersion. The solution is applied to the wall or floor with a spatula with triangular teeth. Adjacent fragments should fit snugly against each other, and in order to remove air and glue excess, the finished coating is rolled with a rubber roller. It should move along the transverse and longitudinal lines, the direction is from the middle to the edges.

- Installation of free-lying tiles. The rubber of the base of the element gives a firm hold to the floor. Each new fragment is applied to the already mounted one, pressed down with a movement from top to bottom.

- How tiles are cut. On the front side, you need to mark the cutting line. With a sharp knife, you need to make an effort along the marking - the cut should go half the thickness of the panel or tile. A fragment can be broken along a line by simply bending it gently. If necessary, the fragment can be cut with a knife to the end (a knife with a hook blade is ideal in this sense). If the neckline is curly, it is better to use a dense template.

Finally, an important stage of installation is control. It will be both intermediate and final. Attach a rail (2 m long) to the coating, let it move in all directions. It is necessary to carefully examine the floor - is there a gap between it and the control bar. The gap should not exceed 4 mm. And the curvature of the seams is easy to check with a marking cord, it should be pulled along the joints, determining the points of greatest deviation of the fragments adjacent to the cord with a ruler.

There should be no more than 1 mm difference.

Well, how the quartz-vinyl adhered to the base is checked as follows: if you knock on the surface of the material, the sound will be muffled at the place where the tile lags behind the floor. If there is no such sound, everything is fine.

Examples in the interior

A review of interior success using quartz-vinyl is an occasion to try on some of the options for a new look of your own home.

Inspirational examples will help with this.

- You can choose bevelled dies, so the floor will acquire some nobility and will not completely merge with the walls.

- The richness of textures is an obvious advantage of quartz vinyl.

- A gentle option for the bedroom that softens the overall look of the space.

- For a loft and its variations, there is also an interesting solution that clearly benefits such an interior.

- Here's an example of what quartz vinyl might look like on a wall.

- Sometimes the floor looks like the most "tidbit" of the interior.

- But the solution to the accent wall in the bedroom is an interesting design, unusual styling significantly transforms the room.

- This is what a quartz vinyl kitchen countertop might look like.

- Even visually, this floor looks very warm.

- If you make such a floor covering, you can harmoniously combine all three main colors in the interior.

Happy decisions!

The comment was sent successfully.