How to make a cultivator with your own hands?

To facilitate physical labor on personal plots, people constantly come up with various devices. One of these is the cultivator. The advantages of this unit are obvious. Moreover, you can either buy it completely ready-made, or assemble it yourself from what is at hand. This will require drawings, some details and advice from those who have already built such devices.

Device

Light hand cultivators are in greatest demand among farmers and summer residents. As a rule, they weigh about 20 kilograms, are small in size and high in performance. The cultivator is able to loosen the ground, remove weeds, and thin out plants. It is even used for fertilizing. With this unique device, not only planting is simplified, but also the process of caring for plants.

Of course, the walk-behind tractor is better in power, but for such small tasks the cultivator is better, since it has more maneuverability and less weight. In addition, it is excellent for areas with difficult terrain or in hard-to-reach places.

The work of cultivators largely depends on which cutters come with it, because it is they who perform loosening and a number of other operations. Among the working attachments for manual models, the following are quite often used:

for loosening the earth;

for cutting;

for hilling;

for making furrows for sowing;

for breaking a strong earth crust (special needle disc);

for plant nutrition (with dispensers).

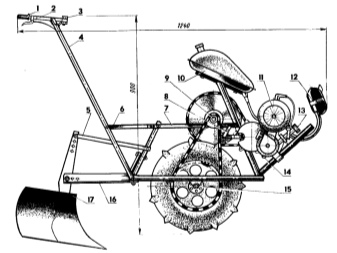

When it is clear which cultivator is needed for certain tasks, you can choose what parts it will consist of. The drawings of a homemade device can help with this. The main part of the cultivator is the engine, which can be electric or internal combustion. It is best to give preference to reliable and durable installations. If necessary, it is necessary to provide a cooling system, since it is not always built-in.

The gearbox is responsible for controlling the engine torque. This part reduces the speed, and also contributes to the operation of the power take-off shaft. As for the frame and portal for attachments, they can be made from what is at hand. Even the simplest two-wheeled car will do for this. The main thing is to think about the diagram in advance in order to have a good idea of how and where the individual elements will be placed.

Convenience and adjustability are important parameters for the control lever. It should be not only comfortable, but also adjustable.

As a rule, the handles are equipped with all the elements responsible for controlling the device. Therefore, it is important to have a good idea in advance of how the unit as a whole will look like, so that it is convenient to use it.

How to do it?

A hand cultivator can be made quickly and easily with your own hands. And do not be afraid that you will need special skills, materials or tools - in most cases, the unit can be assembled from what is already at hand.

If you find detailed instructions, it will take no more than 20-24 hours to assemble the device. A home-made cultivator is also convenient because it is easy to repair or improve.

The simplest model of a universal assistant is a model similar to the "Tornado". Such cultivators operate without fuel and electricity.All work is done with our own efforts and tools. Such a device is made from a pitchfork, while the teeth are bent with a hammer so that they look like a gimbal. Then the simplest shovel handle is attached, a plastic pipe is put on top of it, all this is fixed with electrical tape.

Depending on which cutters are used, cultivators may differ. For example, there are needle models, which are a kind of rotary star device. They do an excellent job of loosening and killing weeds. Even more functions can be performed by the mounted lancet cultivator, its milling cutter resembles "crow's feet" in its appearance. Such an aggregate can loosen, cut weeds, comb out plant residues, level the surface layer of the earth.

It is very easy to make a cultivator yourself today. Many devices can be used for this. For example, gardeners make assistants from a grinder, a bicycle, an old washing machine, a drill, and even a snow blower.

From the grinder

A burnt out grinder can be successfully converted into a cultivator. Of course, such a tool will not be able to handle large areas, but it will help to cope with a summer cottage or even a greenhouse. The main advantages are its environmental friendliness, low weight and ease of use. Such a device works from electricity.

To assemble the unit, you will need a welding machine, as well as at least minimal skills in working with it. Materials for manufacturing will be:

washing machine motor or drill;

reducer from the grinder;

chain and sprockets from a small bike;

bearings;

cultivator cutters, which are made from auto springs;

wheels;

corners;

cable about 50 meters long;

tin to protect the motor from dirt.

The structure will be a metal frame with two wheels. In its center there will be an engine, which must be connected to the cutters. Rotation will be provided by bicycle sprockets and a chain. As for the cable with the trigger, it is attached to the handles.

From trimmer

A regular gasoline garden trimmer, thanks to sleight of hand, can easily turn into a small cultivator. To make it, you will need the following materials:

trimmer (necessarily working);

garden pitchfork;

steel tube.

It will be most convenient to process metal using a grinder, welding and hand tools. The working part will represent the rods from the pitchfork, only curved and flattened. Before work, they must be sharpened with a disc with low abrasiveness. The cutters must be spaced equally from each other using a round element with a diameter of 10 cm. Ideally, if the cultivator is equipped with three cutters.

From a chainsaw

The chainsaw is also suitable for making your own cultivator. The engine from the Druzhba chainsaw is best suited. The creation of a device based on a chainsaw will require, in addition to the engine, a number of materials:

starter;

muffler;

fuel tank;

chain (you can use a bicycle chain or from a light motorcycle);

shaft;

support wheel;

metal corners or steel tube;

wheels of a suitable diameter.

Of the tools, it is advisable to have on hand a grinder, a welding machine, open-end wrenches (set), pliers. First you need to assemble the frame. This is best done using resistance welding or bolts. Then you need to weld the cross members holding the frames together. It is on them that the engine from the chainsaw is installed. The lower part of the frame is supplied with a shaft with wheels, a sprocket and a chain. As a working part, a shaft with cutters is made, the fastening of which is done with square sheets of metal.

Rotary

The discs are a good basis for the cultivator. However, making a rotary device is very difficult, especially if there is no special skill for this. Of the details you will need:

disks;

staples;

axis;

sleeve;

stock;

a pen;

metal pipe.

Disks must be welded to the bushings that are fixed on the axle. With the help of a cotter pin, the axle is fixed in the brackets. A pipe with handles and a crossbar must pass through the large bracket. A rod must be screwed into the small bracket, which protrudes above the crossbar. Such a cultivator is reliable and practical.

From a drill

From a drill, you can make an excellent cultivator that can easily cope with many garden work. Such a device can be made from:

drill (working);

a steel rod (for crimping the drill chuck);

cutters.

Of the tools, you will need a welding machine, emery and a grinder. The shaft in such a device will be a rod with a diameter of 10 mm. It will transfer rotation from the motor to the cutters. This process is carried out through the cartridge.

Cutters can be made from sheets of metal that are suitable for problem areas. Also corners of metal 10-15 cm long and 1 cm wide will come off. Using a grinder, they turn into rectangles, which are then bent at an angle of 90 degrees. Next, you need to sharpen the cutters on both sides and weld them to the rod.

From the bike

Most often, summer residents make a cultivator from a bicycle. This design is characterized by simple installation and no welding. Of the tools you need only a grinder and a set of keys. You can assemble this unit from:

the front of the bike frame;

bicycle wheels;

two-handed saw blades;

pipes for handles.

The saw blade must be attached to the piece of frame. It can be replaced with a plow or other surface that has sharp spikes. The cultivator handles are made longer than the bicycle handlebars and are fixed to the frame with bolts. The wheel is also attached to the frame. The result is an excellent device for loosening the earth, which can always be equipped with a motor.

Useful Tips

Assembling the cultivator on your own must be accompanied by the observance of all safety measures. When using welding, it is very important to protect your eyes reliably. Working with metal, including handling and cutting, requires protection for the face and hands.

Before proceeding with the manufacture of a device or its revision, it is necessary to decide why it is needed. For example, aggregates for removing weeds and simply loosening beds can be very different. For greenhouses, it is worth choosing light models with only manual controls. If the cultivated areas are quite large, then you should opt for options that run on fuel or electricity.

The stages of manufacturing a cultivator are important, but do not forget about the rules for operating this unit. The most important thing is to keep the driving mechanism in working order.

Before starting to work with the device, it is necessary to check the oil level. It is worth noting that it is not worth saving on lubricants, and their replacement should be carried out in a timely manner.

When the cultivator will not be used for a month or more, it must be stored. To do this, it is necessary to remove fuel from it, clean the surface of the engine and all other elements. It is undesirable to clean parts of the device with a strong pressure of water. Metal parts must be lubricated with oil to avoid unwanted corrosion. Store the unit in a dry and dust-free environment.

For information on how to make a cultivator with your own hands, see the next video.

The comment was sent successfully.