Classification of cultivators and their device

Cultivators are widely used on personal subsidiary plots and farms. But this type of technique has its own internal division. It is imperative to pay attention to it both when buying and during operation.

Weight classification

It is the severity that is one of the main criteria when sorting cultivators. Their weight can vary from 9 to 40 kg. Even women and high school students can easily handle the lightest machines. Not every professional farmer can handle the most difficult ones. The ultra-light category includes motor cultivators, the mass of which does not exceed 15 kg, and the engine produces a maximum of 1.5 liters. with.

Important: some manufacturers in this category include mechanisms weighing up to 20 kg, capable of developing power up to 3 liters. with. Therefore, it is necessary to clarify this point every time.

Ultra-light cultivators can only loosen the ground by up to 8 cm. It is recommended to use them for a flower bed, for a flower garden and similar purposes. Thanks to the small working width (no more than 30 cm), this type of cultivator can work even with narrow row spacings and hard-to-reach places.

The power plant in them works either in a two-stroke or in a four-stroke mode. The second option is preferable. As for light cultivators, this group includes machines weighing no more than 40 kg, capable of developing power up to 4.5 liters. with. Increasing the working width up to 40-50 cm immediately expands the possibilities of farmers. After all, the overall performance increases by 50-100% (compared to ultra-light devices).

If you install a small hiller, you can easily and quickly cut furrows for planting any plants. But we must remember that light cultivators can "bounce" when entering the ground. Their mass is not enough to stably stay in one position. Cultivators of the middle category weigh from 45 to 60 kg. They are equipped with motors with a total capacity of 4 to 6 liters. with.

In addition to increasing stability, these machines are good because of the larger covered swath. The depth of cultivation of the land is increasing - it can reach 25-28 cm. But it is worth considering that in narrow places and in hard-to-reach areas, such a technique does its job poorly. On medium-sized cultivators, four-stroke motors are usually installed. The use of both hillers and small plows is allowed.

The heavy class includes motor cultivators that weigh over 60 kg and develop a power of 6 liters. with. and more. All such cars are equipped with four-stroke engines and a full-fledged gearbox by default. This helps to increase the functionality of the technique. The available range of trailed and attached equipment is expanding. Even the processing of large vegetable gardens becomes possible.

Varieties by purpose

But mass is not everything. The combined type of cultivators, thanks to the careful study by the designers, can simultaneously do several agricultural work at once. Almost all of these machines have a strong frame and high productivity. With the help of such motor-cultivators, it is possible in the shortest possible time to redo the structure of the soil in a certain area.

However, the correct choice of device power is of great importance.

Combined cultivators are produced by both domestic and foreign factories. Along with this technique, the inter-row version has become widespread. The creation of such cultivators was a deep breakthrough in personal subsidiary plots.

With their help you can:

- loosen;

- feed;

- weed the ground.

Some inter-row cultivators are capable of fertilizing vegetable crops at the same time as processing the gaps. Differences concern the width of the processed strip and the depth of loosening. Some models can apply liquid top dressing to the ground, and not just solid fertilizers. You can also purchase devices that loosen the soil and prune weeds. It is useful to use the versions with protective discs - they do not damage the plants.

Special varieties of cultivators are intended for processing potatoes. If you use them, you can loosen the earth and break up large lumps, and make the soil horizon smoother. Thanks to such manipulations, the roots of the bushes are supplied with oxygen more efficiently, and moisture retention increases.

Important: if the soil is very difficult, it sometimes has to be loosened in several stages.

Judging by the evaluations of practitioners, the cultivation of potato fields with cultivators increases the yield up to 3 times, while the total time of field work is reduced by at least 2 times.

Special attention should be paid to this type of equipment as a subsoiler. With its help, the soil is loosened deeply (which follows from the name itself), but the layers do not turn over. As a result, the supply of oxygen and nitrogen is improved. When using a subsoiler, you can increase the yield. These devices are suitable for the cultivation of almost all agricultural plants used in Russia. Subsoilers can be equipped with additional attachments that allow fertilizing the ground and performing other manipulations.

A seeder-type cultivator is also a fairly common option. It allows for continuous sowing of grains and legumes while cutting weeds. These functions are harmoniously combined with the addition of granular mixtures and with the rolling of the earth in strips. Such processing turns out to be optimal in places where moisture is insufficient, as well as in areas where the land is severely damaged by wind erosion.

Modern products can work effectively in fields where crop residues are stored.

The differences between the models concern:

- hourly productivity (measured in hectares);

- working speed;

- the width of the captured strip;

- the capacity of the seed and fertilizer bunkers.

A weeding cultivator can be of great benefit. Along with the operation, which its name indicates, this device is able to plow the soil, loosen it, and resist the rooting of weeds. Like other cultivating machines, weeding cultivators are classified by dry weight and by the type of motor installed. This gradation facilitates the selection of mechanisms for processing a specific location. Basically, such devices are equipped with arrow-shaped paws, fixed on special racks, with the help of knives, loosening and cutting unnecessary plants is simplified.

Universal cultivators stand out in a separate class. They can be used both in spring and autumn, on plowed and fallow land. The wide functionality of this technique is justified in fields that differ in soil composition and mode of use. If homogeneous crops are grown, if the processing regime is quite close, you can get by with the use of presowing mechanisms. Therefore, for small farms (for a vegetable garden), specialized equipment is preferable, and for large farms, universal equipment.

The liquid-fertilized row cultivator is mostly used as an attachment to the frame. It is imperative to choose options with overload protection.In order for the liquid to flow from the container evenly, a pump is provided. If the device is equipped with a parallelogram with support wheels, it is possible to successfully work on heavy soils teeming with stones. In practice, the speed of passing the cultivated land is of great importance.

Steam

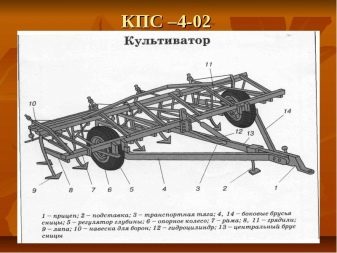

Cultivators, cultivating pairs, can be of the mounted or trailed type. This technique is usually formed on the basis of welded rectangular frames. Adjusting the penetration depth of single paws allows you to change the quality of work. In most modern models, spring protection of the paws is provided. It works without the involvement of workers, reliably preventing breakdowns when working on very hard, stone-rich ground.

When installing the support wheels, they are oriented in relation to the frame so as to maintain the same depth of entry of the working bodies. The paws can cut weeds and loosen the soil. Certain types of paws perform both types of work. Of great importance when choosing, as always, the depth and width of the processed strips.

High-quality cultivators accurately maintain a given depth, level the furrows, their working bodies are distinguished by a long service life and are less clogged.

Cultivated

This is the name of the hinged mechanisms that help inter-row processing of nightshade, sunflower, cereal and other row crops. The difference between the models is related to the number of simultaneously processed rows. Some cultivators can be fitted with a harrow. The addition of hillers is often used. It is recommended to choose products with shortened wings, which throw less land to the side.

Special

This group includes those cultivators that do not belong to row-crop and steam models. As a rule, the paws on them are rigidly attached to the frames. For comparison, other models use a swivel joint. The paws are attached using sections placed on an articulated suspension. This solution improves relief copying.

For pre-sowing soil cultivation

Such machines can prepare the ground for sowing a wide variety of plants. Important: they are not applicable on rocky ground. If the soil is soft, the soil can be loosened properly. With high-quality processing, an accurate final alignment is achieved. Pruning of weeds with different stem thickness is provided.

By aggregation method

Rotary cultivators are preferable for manual cultivation of small suburban areas. Despite the absence of a mechanical drive, the quality and speed of work is increased compared to using hoes, hoes and shovels. The vast majority of structures are equipped with special wheels. Therefore, they can easily roll over the beds and strips. It can also be mounted on extended sticks, which allows you to work with minimal effort.

Trailed

And yet, in most cases, motorized options are used. In large farms, cultivators attached to tractors are used. The trailed type is distinguished by the highest productivity and speed of work. It can be aggregated with tractors of various brands. Some trailed machines are suitable for both seedbed and steam cultivation.

Hinged

Such equipment is intended for pre-sowing cultivation of light and medium-sized lands. Some modifications are suitable for early spring moisture blockage. The best designs can completely prepare the site for seeding in a single pass. The appearance of furrows and ridges on the field is strictly unacceptable.

When loosening the earth, the removal of wet parts of the soil upward or the compaction of any noticeable portion of the soil should be excluded.

Types by type of working bodies

Let's consider several options.

With passive

Cultivators with passive working bodies are widely used in pre-sowing and inter-row cultivation of the land. They can be used at all stages of the growing season of plants. A striking example is the universal cultivating machine of the USMK-5.4 model, which is designed for the cultivation of sugar and fodder beets. The kit includes:

- universal lancet paws;

- flat-cutting paws for weeding;

- toothed lightweight harrows;

- rotary bodies;

- feeding apparatus;

- discs for protection.

- With active

The milling cultivator type helps to confidently cultivate heavy, abundantly water-saturated soils. The work is going well, even if they are salted. In such cases, passive equipment fails. The main working body in this case is a milling drum. Install it on a section attached to the frame by means of hinges.

If the drum is placed vertically, it is possible to carry out pre-sowing preparation of soils with complex granulometric structure to a moderate depth.

Important: Most models with this drum arrangement are not suitable for work in areas where wind erosion is strong.

They will also not help if the ground is saturated with stones larger than 15 cm in diameter. The stubble area can be cultivated with steam and flat-cut cultivators. Both of these types can cultivate the soil to a depth of 16 cm.

A rotary cultivator is a device that is equipped with special cutters. It is such a working part that is most often set in motion with the help of a rotor. Disc type cutters are also mounted on the rotors. They are able to dig grooves for potatoes, as well as prepare moldboard edges. Also, this type of cutter is great for cutting the beds.

With spring

This category includes, first of all, hillers working on stony soil. Special spring struts are placed separately on the right and left. Spring tines are used on row-crop cultivators. There they help to loosen the soil in particularly unstable areas and in the aisles. As a result, the functionality of the hardware increases.

The so-called crow's feet deserve special attention. This name went to a special type of soil milling cutters. They are initially made non-separable, and high-grade steel is used in their manufacture.

Such tools are attractive when cultivating hard land.

An example of a cultivator with S-shaped paws is the KPZ-9.7 and KShP-8 models. They are widely used in pre-sowing soil preparation. At this moment, loosening is carried out to a depth of 6 to 12 cm. In addition, the surface is leveled, and pairs can be processed. The racks are arranged in four rows.

Device

The basic elements of any cultivator are:

- frame (which holds the components);

- motors (most often gasoline);

- fuel tank;

- control sticks;

- rotor parts for attaching cutters;

- brackets for openers and other mounted implements;

- engines;

- wheels;

- pulleys and belts (connecting the motor and the propeller);

- spark plugs and other components of the ignition system.

An important role, as already mentioned, is played by cultivator stands. Developers are careful about defining their geometry. A high-quality rack should be made only of a special type of steel with a high degree of elasticity. This allows you to restore the original shape after significant stress. Cultivators with flat cutters can be suitable for cultivating row spacings and steppe soils suffering from insufficient moisture and from wind erosion.

Most often, flat-cut cultivators are supplemented with arrow-shaped tines. They are mounted on vertical racks. Carefully thought-out design helps in gardens, water and soil protection zones. Cultivator gears play an important role.It is advisable to replace these parts as close as possible to the original ones, sometimes they are even made to order according to worn out or broken samples.

For how to work with a cultivator, see the next video.

The comment was sent successfully.