How to choose a waterproof laminate for class 34 tiles in the kitchen?

The choice of flooring for the kitchen is a very serious question, because, in addition to its appearance, it is important that the coating is moisture resistant and durable. From the article you will find out if laminate flooring can be used in the kitchen, how to choose and install it.

Main types and characteristics

Laminate is a practical, modern and beautiful way to transform a room. But for the kitchen, only material of a certain quality can be suitable.

The laminate that is used for the kitchen is most often in the form of a tile, that is, square, so it is easy to deal with it.

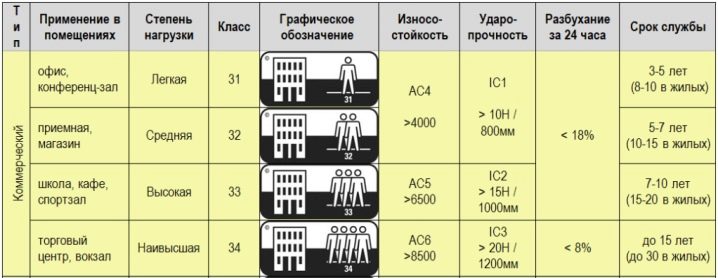

In terms of performance, the laminate is divided into classes.

- Class 31. Good coverage for the apartment. Capable of withstanding loads, but not suitable for corridors or kitchens.

- Class 32. This material has great wear resistance. Often used as a coating in kitchens and offices.

- Class 33. Suitable for rooms with high traffic. This is ideal for a corridor, small cafe, showroom.

- Class 34. This is the highest quality laminate, which is used in high traffic areas such as business centers, large halls of cafes and clubs.

For the kitchen, class 34 will be the most practical: this coating is the most resistant to mechanical damage. About him in more detail and will be discussed further.

Advantages and disadvantages

Class 34 laminate is considered the most wear-resistant and durable, so these qualities will be its main advantages. But it is worth considering other advantages of the material.

- Resistant to moisture. This quality is due to the application of special resin solutions in several layers, not only on the main surface, but also on locks, joints, ends.

- Refractoriness. The material has the highest class of protection against fire, so even a small spark will not leave marks on the surface.

- The slats are easy to install. All elements are connected using locks that simply snap into place.

- Environmentally friendly material. The production of this class is based on only natural raw materials. The coating can even be used in nurseries.

- Only this class laminate flooring can be used with underfloor heating systems.

It is unacceptable to use laminate of lower class.

Many positive qualities of the material make it profitable, but there is still a drawback - this is the high cost of the material. However, with all the performance properties and proper care, the price looks quite justified.

Structure

Class 34 laminate has 4 layers. This allows it to be the most durable and durable.

- Stabilizing layer. This is the lowest and most important layer. The rigidity of the material and the period of its use depend on what it will be. Manufacturers often supplement this layer with sound insulation, which makes it even more beneficial to use.

- Base layer (in other words, carrier). HDF boards for class 34 are 850 kg / m3. This increases all the properties of the material: sound insulation, noise absorption and durability.

- The outer layer is the decorative layer of the laminate. On a special paper base, a drawing is applied that imitates stone, wood or other, provided for by a specific collection.

- Protective. The operating time depends on what this layer will be. Special resins are used for coating.

Different collections may differ from each other by additional layers: insulation, additional waterproofing, etc.

Moisture resistance

Class 34 laminate perfectly tolerates short-term contact with moisture, but it cannot be called hydrophobic. It does not deform from high humidity.

To ensure good moisture resistance, manufacturers use special solutions that are used not only on the outside. A high-quality laminate is characterized by the processing of the bottom surface, joints and ends of the material. After installation, additional seams are recommended. Therefore, it is quite justified to consider this class of laminate waterproof.

Floor covering manufacturers

The market for building materials, including flooring, is growing by leaps and bounds. New firms and companies appear every day. But conventionally all can be divided into three groups.

- Chinese fake. Yes, oddly enough, but even here you can run into a fake. According to the documentation, all production is located in Europe. The names of such companies often have similar combinations with well-known brands. But in fact, everything is imported from China.

- Companies that are licensed, but only copy well-known manufacturers. In fact, this is also a fake, but legally. There are a lot of such firms. They are scattered all over the world, so it is very easy to fall for the bait of unscrupulous manufacturers. Firms often have names of two or more words, one of which is consonant with well-known brands. Thus, firms hide behind the fact that they are subsidiaries, and calmly do their dirty work.

- Giant firms. World famous brands, the name of which is used by the two previous types. They produce coatings of the highest quality and from high quality materials. They work only with large stores, produce custom-made laminate flooring and 100% prepayment. As a rule, these are the most expensive types of laminate.

The most widespread firms on the Russian market are: Tarkett (Germany), Egger (Germany), Gastilla, and Maister... All other companies may turn out to be both new future empires and low quality laminate manufacturers. The Tarkett company, for example, gives a guarantee for its materials, and buying flooring from them, you don't have to worry for the next 20 years.

Kronostar Is a domestic manufacturer that guarantees high quality at a reasonable price. The principle "price - quality" is clearly observed here. The production of the material is located in Russia, which makes it possible to make the price lower than that of foreign companies.

Care Tips

Laminate is not picky, but even without proper care, the service life will be short-lived. It is worth washing the laminate with a damp cloth and without using aggressive solutions. This will help preserve the original look of the material.

If suddenly moisture gets on the coating, then simply wiping it will not be enough, especially for the 32nd class.

It is worth walking along the joints with special care and wiping everything dry.

For the best effect of water resistance, the joints of the lamellas should be treated with a specially developed mastic from the same manufacturer as the laminate. This procedure should be carried out every 2-3 months.

According to the manufacturer, the average lifespan of a laminate is 10-15 years. But practice shows that with proper care, the service life is much longer.

For information on how to perform the correct installation of artistic laminate, see the video below.

The comment was sent successfully.