Choosing a maize chopper

Knowing how to choose a chopper for corn is important for any person who grows and processes it. It is also necessary to understand the types of grinders (crushers) for corn on the cob, its stalks and crop residues.

Device

The maize crusher is usually designed for manual or automatic operation. Fully manual systems are found on small farms. Most often, a non-mechanized corn grinder can process no more than 100 kg of plant mass per hour. An automatic device has special electronic components that set a particular program. All such devices are equipped with an electric drive and can be used in large agricultural enterprises.

Sometimes even the supply of raw materials in buckets to the tank does not justify itself. In this case, the most rational use of the conveyor. Some plants are capable of processing up to 4 tons of raw materials in a typical 8 hours. Despite this difference, the basic structural elements are more or less the same. These include:

- drum (inside which the grains stand out from the cobs);

- a peeling device (also helping to pull grain out of the cabbage);

- container (container for collecting seeds);

- drive unit.

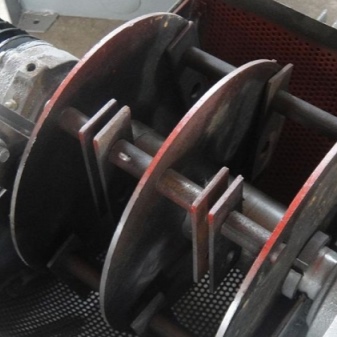

The drum is the most complex in its internal structure. It distinguishes:

- channel for loading (handing over) cobs;

- compartment for peeled fruits;

- the outlet through which the stems and tops are thrown out.

But, of course, this is only the most general description of the conditioner. Its working part is most often mounted on the engine itself. This device allows the grain to be processed evenly.

The frame also plays an important role - this metal part allows you to maintain the stability of the structure. The outer casing protects the main mechanisms from unwanted influences.

A metal hopper will receive raw materials. To control the volume of the incoming mass, a damper is provided. The electric motor is connected to a mechanical drive. Spent corn kernels rush outward along the unloading auger. But it doesn't end there.

The product is taken from the unloading auger in order to do something with it further. The type of working part determines the quality of processing. It is necessary to control that stones and other solid objects do not penetrate inside, otherwise the serviceability of the device will be in question. The crushed grain is driven through a sieve, and the cross-section of its holes determines the size of the grinding.

Attention: all mechanisms and components wear out during use, therefore they need continuous maintenance.

Views

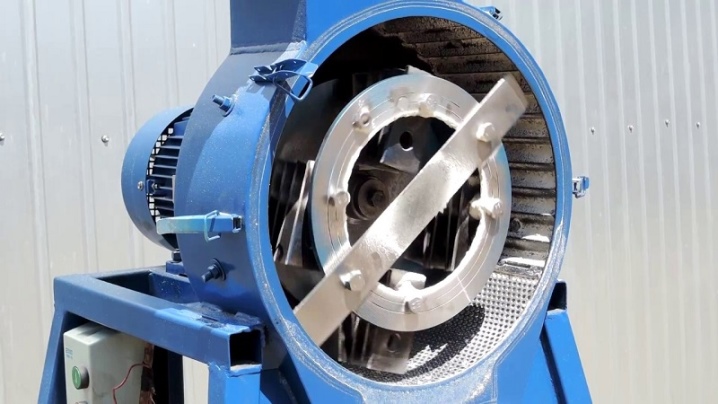

The most important thing is that all shredders are clearly divided into home-made and factory-made equipment. The second option is usually more productive. But the first is cheaper and more flexible to fit specific tasks. Important: devices of any kind should only crimp grain that has reached wax ripeness. It contains much more nutrients than a dried product. The jaw version of the shredder works thanks to a pair of plates. One of them is fixed rigidly, the other rotates. The crushing of the grain mass occurs when it is in the gap separating the plates.

Rotary models are arranged differently - in them the main work is performed, as you might guess, by rotors with fixed hammers. Another type is cone devices. As the cone rotates, grain falls on it. In this case, it is precisely the crushing of this grain that occurs.Hammer devices differ from rotary ones in that the working parts are mounted on hinges. When hitting them, the corn fruit will split. In the roller system, flattening is ensured by running through special rollers.

How to use?

The grain is filled in with a locked valve. After it enters the receiving hopper, the valve is smoothly opened. Further in the working compartment, the rotating knives will grind it. The crushed mass is driven through a sieve. The device for stalks works differently:

- they are loaded into a rectangular hatch located on the side;

- tops are passed through special knives;

- the crushed mass ends up in the hopper.

Corn on the cob is ground in a similar manner. The raw materials are placed in a rectangular hatch. The traction pushes the cobs into the working part. There they are chopped by knives with a radial arrangement. The crushed raw material goes back to the bunker, and there it is completely ready; for crop residues, they buy completely different shredders that work in the field.

How to choose?

Main criteria:

- intended purpose (work in a private household or on a large farm);

- required power level;

- device dimensions;

- total productivity for the season;

- reputation of the manufacturer;

- reviews.

Manufacturers

- Very well suited for medium-sized farms "Electrotmash IZ-05M"... The device is equipped with a 800 kW drive. Up to 170 kg of corn is processed in 1 hour. The receiving tank holds up to 5 liters of grain. The capacity of the working compartment is 6 liters.

- It performs very well and "Piggy"... This Russian shredder is compact. Proven materials are used in its creation. The starting hopper can hold up to 10 kg of product. Current consumption per hour - 1.9 kW.

- "Farmer IZE-25M":

- equipped with a 1.3 MW motor;

- develops an hourly capacity of 400 kg;

- has a self-weight of 7.3 kg;

- adjusts the grinding level;

- does not have a receiving hopper.

- Alternative - "TermMix". This shredder is equipped with a 500 kW motor. This allows him to process up to 500 kg of corn per hour. The device weighs 10 kg. The receiving hopper holds 35 liters of grain.

The comment was sent successfully.