How to make a bed with your own hands?

There is no piece of furniture more important in a modern apartment than a bed. A person needs to rest after a hard day's work, and the bed can help with this. Of course, choosing a bed is not an easy task, and often just impossible. If, for some reason, choosing a bed for a pleasant stay did not work out, you can always cope on your own. The following will describe how to make a bed with your own hands.

Views

A simple, most familiar model, chosen by many precisely because of the simplicity of execution. Four legs, two lateral fixings on the sides, two backs and a slatted bottom. In a word - a classic.

A further step in modern bed-making was the equipping of their products with boxes - for storing various things in them, from bed linen to some personal items. Almost any bed can be equipped with boxes, even after the end of its assembly.

Today transforming beds are gaining popularity. As the name implies, such a bed can be turned into a completely different piece of furniture with a slight movement of the hand. It allows you to save a lot of free space in the apartment.

There are also a lot of transformation options, and here are the main ones:

- Wardrobe bed... The frame of such beds is often made of light, but strong metals that can not deform under constant stress during sleep, as well as when stored in a folded state. The bed itself is a vertical structure with three walls, built-in drawers and a lifting mechanism on which the frame is installed.

When folded, the cabinet can be closed both with the bottom of the frame and with special doors that open during sleep. The big disadvantage of this design is the limited number of things that can be placed in the drawers of the cabinet. These will not be used very often. However, the place that will help to save such a bed most often covers this minus.

- Bed-table... Most often, this type of transformation is used in families with children attending school. The size of the table (and the bed that comes out of it) is very limited, and it is quite difficult for an adult to enjoy a pleasant sleep. To strengthen the entire structure, a furniture wall with cabinets and shelves is used, into which a table is mounted, the distant part of which turns into a bed.

- Perhaps, armchair-bed is the most common type of folding beds without a frame in most apartments. Such products are also called frameless. An additional place to sleep for one person, as well as a comfortable chair for the rest of the time, is better than you can imagine.Previously, such an armchair was an integral part of a set with a sofa, but today, due to the growing popularity of apartment decoration in the style of minimalism, the fashion for such products is rapidly disappearing.

- Pouf bed... The same transforming bed, but without armrests and backrest. A modern folding bed with quality fillings and box springs. This option is suitable for almost any apartment, since this product takes up very little space, folds into bed in just seconds and is ideal for sleeping.

Folding horizontal products can be considered a separate type of beds that can be made by hand. Such models differ from transformers in that they do not turn into some separate piece of furniture, but are folded with the help of a special mechanism into a furniture wall, into which almost everything necessary can be additionally built.

Floating beds are the squeak of modern fashion. They, of course, do not float, but due to the original organization of the elements that hold the bed, it seems as if nothing is holding it at all. The decision to make and install such a model in your apartment is quite daring, but at the same time it is extremely interesting.

There are many different options for decorating the space under the bed. There are lighting, shimmering with all the colors of the rainbow and creating the effect of romance and mystery, and various rugs that turn the room into a soft, pleasant room. There are many options, just connect your imagination.

The last variety worth talking about is hanging beds. They look very beautiful and truly unique, although it will be easier to make such a bed even with your own hands than other pieces of furniture. The main condition for using this type of berth is the ability to allocate a sufficiently large space for it, since the suspension mechanism tends to swing with a small amplitude.

Determine the size

When making something with your own hands, you need to take into account a lot of things. When choosing a bed, its size will be a very important factor. Of course, the size also depends on a variety of nuances.

The first nuance is the need for a certain number of sleeping places in the room. If the room allows, then you can provide it with a bed of absolutely any size. Of course, many make classic singles and doubles. So, the following nuance emerges.

For almost any bed made by yourself, you need to choose a mattress, which should very clearly fit in size to the size of the bed. This is a very important choice, since an improperly selected mattress can lead to poor sleep, leading to various nervous disorders, psychosis, as well as problems with the human skeleton. At the present time, mattresses are made in the following size ranges:

- 90×200;

- 120×200;

- 140×200;

- 180×200;

- 160×200;

- 80×190;

- 180×80;

- 90×190;

- 70×160;

- 120×180;

- 150×200;

- 90×180;

- 170×80.

Focusing on this dimensional grid, it is worth calculating the size of the future bed. Of course, everything should be done as carefully as possible. There shouldn't be any inaccuracies.

Mattress base options

Having decided on the dimensions, you can proceed to the selection of such an important part of the bed as the base for the mattress. Yes, of course, you can do without a mattress, replacing it with a non-removable filler of the same chair-beds and similar furniture, but at home it is extremely difficult to do this, therefore, most often the beds are made under the mattress.

They are like this:

- Today it is already considered a relic of the past, but in some places you can still see a flat base. It consists of boards hammered together, forming wooden shield, on which the mattress is laid. There are practically no advantages to this design (compared to more modern options), but there are a lot of disadvantages.

First, the mattress deforms very quickly and loses its useful properties. Secondly, a dream with such a reason is not the most pleasant. Thirdly, the mattress is not ventilated, because of which it can become damp, which will lead to the appearance of various parasites in it or the beginning of rotting, which is also not very pleasant.

- Slatted bottom... The most common base option. Such a product is sold in almost any store and can be replaced with a slight movement of the hand. It consists of several bending strips (lamellas) made of different materials (most often wood is used), placed at an equal small distance from each other and laid on the frame. It fits directly into the mattress niche.

There are options with shock absorbers that automatically distribute weight throughout the mattress, and products without them, designed for light loads. If something happens to the lamellas, as mentioned above, they can be replaced even one at a time.

- Orthopedic... At such a bottom, a metal frame always lies at the base - a pipe that holds the entire structure. Lamellas at such a base bend better - due to a special manufacturing method associated with gluing the material from which the parts are made. The so-called lateral holders, made of plastic and designed to hold the lamellas, are attached to the frame.

- Plastic... Such bases are quite different from all previous options in that they rely on plastic springs, which allow to provide better elasticity of the frame and the ability to control the level of rigidity of the berth. Of course, this option is also more expensive, but its orthopedic component makes one think a hundred times about whether it is worth saving on health.

Features of the metal product

When choosing various metals as the main materials for making a bed, you should make sure that the selected material will be as strong as possible and capable of withstanding heavy loads. Today, beds made of metal are even cheaper than their wooden counterparts. Most often, profile pipes are used for the manufacture of the frame, with which it is easier to work. Buying them is also quite simple.

As in any business, the manufacture of a metal bed frame is fraught with various difficulties. At home, for example, it is almost impossible to make such products, because it is necessary to have a rather specific tool for cutting, processing and welding metal structures. However, all efforts will be justified, since the end result is a bed that will serve faithfully for many years. It is possible that even more than one generation.

It should also be borne in mind that the metal bed:

- Has more weight than analogues.

- It is often not demountable, so the place for installation must be chosen wisely.

- Due to joints and poorly processed welds, it can damage interior elements, the floor, and cause injury to both children and adults.

It is possible to make a bed even from polypropylene pipes, which will be much cheaper, more convenient to compose, but at the same time less durable. Such structures are not designed for heavy weight, and it is recommended to use them only for the manufacture of baby beds. Of course, no one forbids making an adult bed, but this is fraught with its rapid deformation, destruction - and just a bad dream.

Popular materials

Having decided on the size, frame and base for the mattress, it is worth thinking about another very important element. About the material from which all the previous elements will be made. Of course, wood will be the most environmentally friendly, visually pleasing and aesthetically correct choice, but its cost can scare off many craftsmen.

If the price is not the main thing for you, then you should pay attention to the fact that you need to choose only the highest quality wood species for the bed, such as oak, beech, ash, mahogany, birch and others. The materials must be well dried and free from the slightest cracks. Of course, there should be no knots either. These can be boards or bars, fastened with a special glue - in order to obtain the so-called glued boards. When the boards are ready, they are coated with a special water-based varnish that will preserve their appearance and protect them from moisture for many years.

- The most difficult type of tree to understand is aspen... For some reason, it is this tree that many masters (and ordinary people) associate with various superstitions, which differ so much that it is extremely difficult for an unprepared person to understand this, and often impossible.

Of course, this tree species is famous not only for superstitions. Even the most skilled connoisseurs cannot decide what time of year it is best to cut aspen for further processing. Some say that this is the end of spring, others prefer the end of summer. In general, everything is very ambiguous.

- The most popular and cheapest material today is becoming PVC - or polyvinyl chloride... This material is a colorless plastic, very convenient for processing and further use. It has average characteristics in terms of price-quality ratio, which is why it is so popular, however, experts say that polyvinyl chloride, when heated, emits dangerous fumes that can harm human health.

- Approximately at the same level of popularity with PVC is MDF - or fine fraction... The name, of course, sounds rather unusual, but in reality these are just plates made by the method of high pressure (from medium density wood fibers).

MDF has a rather obvious disadvantage. Of course, we are talking about a very bad combination with water. Too much moisture for such a material is destructive, since dry compressed fibers swell, destroying the original structure of the board, as well as the paint and varnish coating, which greatly affects the appearance and the possibility of further operation of the product as a whole.

- As mentioned above, in addition to wood and plastic, beds are also used various metals, from simple sheet iron to gold and platinum. The features of this choice are described in the corresponding section.

How to make a two-tier model at home?

It may seem that making a bunk bed is not very necessary for most people, but for families raising two or more children, such a model is a real salvation. Of course, if there is a separate children's room, then you can put a couple of beds for each baby, but is it worth cluttering up the extra space that can be used under the Swedish wall, for example.

Wooden

Such a model is the simplest of all possible, so almost any (even a beginner) master can make it. These beds are called classic. Such furniture consists of only 11 necessary elements:

- vertical racks - 4 pcs.;

- pads for vertical posts - 4 pcs.;

- drawers - 4 pcs.;

- longitudinal strips for frame boards - 4 pcs.;

- headboard and footboard upper panels - 4 pcs .;

- central planks of the headboard and footboard - 4 pcs.;

- stair railings - 1 pc .;

- stair steps - 3 pcs.;

- guardrails - 4 pcs.;

- slats for the base of the mattress - 24 pcs.;

- end boards of the supporting frame - 4 pcs.

- First you need to install the headboard and footboard. To do this, the corresponding upper and central strips are attached to the vertical posts at the required level.

- Then the drawers are installed in special grooves, which are attached with self-tapping screws.

- After installing the structure, you can start fixing the railing of the staircase and its steps.

- We can say that the assembly is complete. It remains only to additionally process all the joints in order to avoid the appearance of burrs and chips, as well as to install the fence slats on both beds and lay the cross slats to support the mattress.

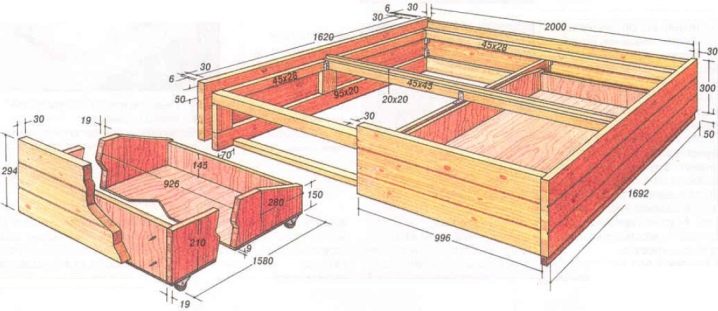

How to assemble a pull-out podium bed?

The podium bed is one of the varieties of transformers, however, this furniture differs from them in that it does not turn itself into another piece of furniture, but when folded becomes part of the room as a whole. The podium is an artificial elevation that serves as the floor in the room.

When you are going to start assembling, you need to realize that making such a complex structure is, albeit a very practical solution, but at the same time such work is very difficult. To install such furniture, you should contact a specialist.

If the services of a specialist are not needed, then here are some assembly tips:

- First, you need to draw a sketch of the future podium - along with a built-in bed. To do this, you need to know as accurately as possible the dimensions of the room, the height of the bed frame, its width and length, the height of the mattress that will be used for sleeping, as well as the height of the wheels with which the bed will roll out of its "storage".

Instead of wheels, you can use a special mechanism, but its installation must also be taken into account in the calculations, since its parts make the bed somewhat wider. In no case should you choose the height of the bed frame close to the opening from which it will be removed, in order to avoid getting stuck and other problems with operation.

- As soon as the sketch is finished, everything is measured with millimeter precision, it is necessary proceed with the selection of materials from which all elements will be created. When creating such structures, you should pay attention to the additional strengthening of the podium supports - in order to avoid collapse. It is recommended to use plywood or MDF as a podium floor, since they have the necessary strength, but at the same time are not very heavy.

- After choosing the materials, you can start assembling, but before that you need to dismantle the skirting boards, since they will definitely interfere with the installation of the frame. At the initial stage, according to a previously drawn up sketch, it is necessary to assemble a frame in which space should be left for the bed itself, storage space for other things, as well as stairs. The next step in the assembly will be the bed frame, also created from the sketch. After all the manipulations, all that remains is to assemble the storage boxes, sheathe the podium frame with plywood or MDF and attach a ladder.

Everything. The podium bed is ready.

Homemade model with a lifting mechanism: step by step instructions

As is the case with any other bed - the assembly of this model must be started by creating a drawing. The more detailed and better it is made, the easier it will be to assemble the bed. It is hard to learn, easy to fight. If there is no experience in assembling such beds, then you can take ready-made drawings on the Internet or from manufacturers.

So, the drawing is ready, it's time to decide on the necessary materials and tools. For assembly, you will need boards, wooden slats, chipboard (chipboard), self-tapping screws with a set of screwdrivers and a lifting mechanism. Unfortunately, making it with your own hands is extremely difficult, so you have to buy it. The lifting mechanism is gas and mechanical. The gas mechanism can be fixed in a certain position and without.

Once everything you need is assembled, you can proceed to the most important thing - to the preparation of parts and assembly:

- First, it is necessary to make sidewalls, drawers, headboards, and also bottoms for boxes from chipboard or MDF.

- From a bar, you need to assemble a frame for the base.

- Then the base for the mattress is created - from boards and wooden slats.

- A frame can be assembled from these parts.Once the frame is assembled, the bed is almost complete. It remains only to attach the drawers and sidewalls, attach the bottom of the drawers and fix the headboard.

- The final touch will be the installation of the lifting mechanism and the sheathing of the finished product. For cladding, it is best to use foam rubber sheets laid in several layers. This will add softness and comfort to the garment, as well as hide any sharp corners.

You can cover the foam rubber with a cloth or other materials - such as leatherette or leather. The main thing is that the selected material matches the general interior of the room. This will give the bed an aesthetic look and completeness.

How to make a round bed correctly?

Round beds, although they are interesting interior solutions, are still not installed in apartments very often, since not everyone can afford to install such a piece of furniture in the center of the room, where it belongs. In the corner, he will "eat" free space.

As before, preparation should begin with a drawing, the most important detail of any business. It is necessary to match the size of the room in which the bed will be installed with the future dimensions of the bed itself. Most often, round models are made double.

Having decided on the dimensions and having prepared everything you need, you can start making parts and assembling:

- To begin with, two semicircles must be cut out of two sheets of MDF or plywood using special measuring tools - the future base for the bed.

- A cross piece specially assembled from bars equal in length to the diameter of the base is attached to the finished circle, on which the legs are installed and another cross, crowning the bed frame.

- After the preparation of the crosses, additional legs are installed around the perimeter of the circle, designed for better stability of the bed.

- After these manipulations, the frame is turned over - and we can say that its assembly is complete. The last step in the creation will be the installation of the sides for the mattress made of thin plywood, as well as covering the finished product with foam rubber (for softness) and fabric (for beauty).

Decor options

As mentioned above, the assembly of the bed largely depends on the imagination of the assembler and his ability to pay, which gives a lot of options for the final product. If we talk about decoration, then in this regard, the number of options is simply enormous. The main thing is to be able to choose the appropriate method. It takes good taste for that.

With the help of various decorative figurines, inlays, imitation of precious stones or real jewelry, carvings, combinations of different types of upholstery and other options, even the simplest bed can be turned into a work of art. Even simple leather or leatherette can completely change the look of a bed. If you add a carriage coupler there, the result will be simply amazing.

In decorating, you should not go too far, as in any other business, otherwise all the efforts made will lead to pretentiousness and loss of beauty of the finished product.

Interesting ideas

In addition to the types of beds described above that you can create with your own hands, there are also quite unusual ones - and very interesting for use in the interior.

One of these non-standard solutions is a bed made from plastic bottles. Of course, this is not the pinnacle of art, and the convenience of such a design is highly questionable. However, if you equip such furniture with lighting, and use the bottles as many legs under a real base under the mattress, then it can turn out very, very good.

Loft-style beds are non-standard, but gaining popularity in the modern world. By itself, this style implies the design of the entire room in the form of a workshop or factory room, so the bed must be appropriate. You can, for example, hang it from the ceiling so that it stays there on a special structure until the appointed hour.At night, the bed is lowered and used for its intended purpose. An interesting frameless solution, you won’t say anything.

The last type of non-standard beds can be called beds made in the Japanese style. In the Land of the Rising Sun, the principle of strict minimalism is largely used. This also applies to beds. They look very interesting, and many people notice it.

For information on how to make a bed with your own hands, see the next video.

The comment was sent successfully.