Timber beds: sturdy furniture for your bedroom

Furniture made of wooden beams has been at the peak of popularity for many years. It is distinguished by its high quality, durability, environmental friendliness and very interesting design. Wooden beams are very popular in the manufacture of beds, it is very strong furniture for the bedroom.

You can easily find a suitable option for a bed made of timber in one of the many stores, but if you wish, you can make this product yourself.

You can build a structure with your own hands from glued, profiled, rounded or planed beams.

Dimensions (edit)

Timber beds come in different sizes, they are divided into certain types depending on the design. It can be a double model, one-and-a-half, single, children's, as well as a podium bed, loft bed or other options. It is worth dwelling in more detail on the most popular models.

Double

These bed models are very comfortable and spacious, it will be as comfortable to rest on them as possible. Wooden double beds are modern, practical and sustainable.

Models equipped with a backrest are considered especially comfortable. It can have carved elements and figures that will become an additional decor for the bedroom interior, as well as soft upholstery. Most often it is made from polyurethane foam.

A double bed made of timber will look great in any modern interior.

Single

Small single beds are most commonly purchased for children and teenagers. For them, the bed is usually not only a place to sleep, but also a relaxation area where they can listen to music, watch movies, read books.

A bed made of wooden beams will be an excellent option for a children's room. It fully complies with all the most important requirements for such products: strength, comfort and absolute safety of materials for the health of the child. Another plus of models made of beams: this material is quite warm, which means that it will not let the cold pass from the walls and other surfaces of the room. It is also worth noting that the product can be supplemented with a special protective board made of wood.

A wide range of different colors of single beds is on sale. Together with your child, you can choose the shade of wood that will suit him and harmoniously fit into the interior of the child's room.

Attics

The loft bed is a two-tier structure. Both tiers can be equipped with berths. However, there are models in which a comfortable workplace is located on the first tier (a desk with drawers, a wardrobe or a chest of drawers), and on the second tier there is a comfortable bed.

Loft beds made of timber are very popular among consumers because they are of high quality, reliability, compactness and functionality, as well as stylish appearance.

Podiums

This option is the easiest to make on your own. A homemade bed-podium made of beams looks very modern and stylish. It can be installed both in a large bedroom and in a small one - this option is universal. The most important thing is to properly plan the situation. If the room is very small, the sleeping place can be equipped under the podium, and on it you can organize a recreation area or a study.

Diy products from beams

There are any designs of beds of our own production.

If you are going to create a piece of furniture with your own hands, keep in mind that it is best to use a design option that provides:

- Support of the product in the form of four or six legs, the height of which will be very small - about 20 cm.

- A frame from a bar. It will be the basis of the entire structure, which should rest on the legs.

- Additional strut in the middle of the frame. It will provide reinforcement to the structure. This spacer will sort of divide the bed into two parts.

- Lamellas are cross bars that are installed inside the frame. The mattress will fit on them.

- Backrest. It is made from solid boards or plywood sheets. The backrest will be attached to the vertical supports.

When deciding on the dimensions of the product, adhere to the following parameters:

- the distance from the floor to the upper border of the frame is from 25 to 30 cm;

- the length of the legs is from 20 to 25 cm;

- width of a one-and-a-half bed - from 150 to 170 cm;

- the width of the double bed is from 180 to 200 cm;

- bed length - from 200 to 220 cm;

- back size - is selected individually (most often - no more than 80 cm).

Necessary materials

To create such products, you will need to purchase the following materials:

- bars - the cross-section of the bars should be 5 × 10 or 5 × 15 cm;

- board for the side: the width of the board should be in the range from 30 to 35 cm, and the thickness should be more than 2 cm;

- for lamellas - bars 3 × 5 cm;

- mounts - ordinary metal corners are perfect;

- a sheet of plywood to create the back;

- self-tapping screws, glue and various finishing materials.

Stages of work

Beds should be made in a specific order. In order for the product to be of high quality and durable, certain recommendations must be taken into account.

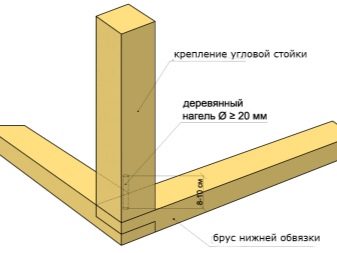

Support and frame creation

It is necessary to cut blanks for the frame from bars with a cross section of 50 × 100 mm. For greater structural strength, it is better to use bars with a section of 100 × 100 mm. The resulting blanks must be connected to each other using self-tapping screws and corners. This will assemble the frame, in the middle of which an additional spacer should be installed. Then you will need to cut out 4 or 6 identical legs and attach them to the underside of the frame.

Attach support bars 4 × 4 cm to the inner side surfaces of the frame using self-tapping screws.They will become the basis on which the lamellas can be laid. Place the lamella support at the bottom of the frame. In this version, the edges of the frame will be able to fix the mattress.

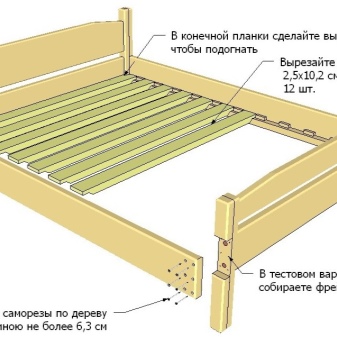

Slats and back

First you will need to cut out the slats. Their size should correspond to the width of the frame, inside which they will fit.

Finished lamellas should be laid at a short distance from each other (about 5 cm). They can be fixed on the support bars with self-tapping screws.

Then you need to attach two bars to the legs (about 7 cm long). Already to them you can attach the future headboard (from boards or a sheet of plywood).

Finishing

In order for the finished product to have an aesthetic appearance, it is necessary to pay special attention to its finishing. First you need to sand all wood surfaces. This is necessary in order to eliminate any irregularities.

Then, using a putty, you need to fill all the gaps in the surfaces of the structure. Match its color to the shade of the wood you use to create the bed.

After the putty has completely dried, it is necessary to sand the finished areas again. After that, you need to carefully wipe the dust from the surface of the product.

Now all that remains is to cover the finished product with varnish or paint it. For these purposes, use high-quality, quick-drying and non-toxic materials.

When the varnish or paint is completely dry, you can lay the mattress on the finished bed and use the resulting comfortable and high-quality product.

For information on how to make a bed with your own hands, see the next video.

The comment was sent successfully.