Gas lift for a chair: dimensions, selection and replacement rules

Today, almost every office has a special, so-called office chair, on which employees sit at their desks. It is much more comfortable than a regular chair, because it allows you to adjust the height, allowing you to choose the best level for a particular seated person. In addition, in such a chair, you can recline the back if necessary. One of the most frequent breakdowns of such chairs is the loss of the ability to adjust the height of the seat. And the reason for this is a malfunction of such a part as a gas lift. Let's try to figure out what kind of detail it is and what it is.

What it is

The gas lift, which is an integral part of office chairs, is a device that in its appearance resembles a truck body lifting system, but is slightly smaller in size. Another name for this device is a gas spring.

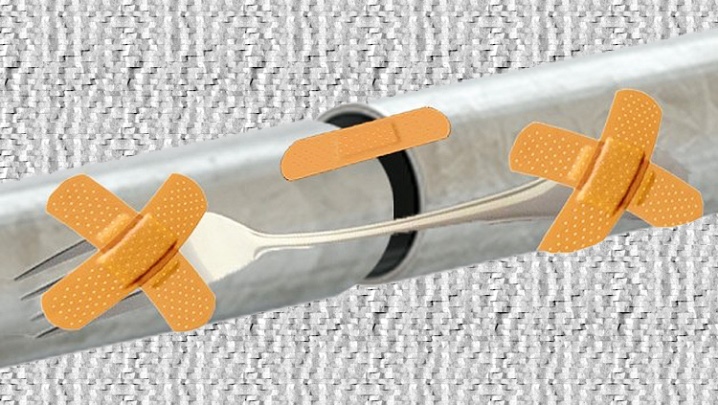

Externally, the gas lift for the chair is a metal pipe with a couple of parts of various sizes.

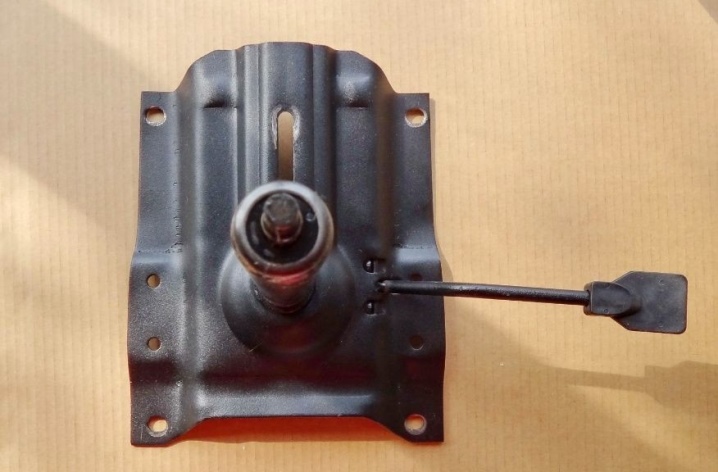

The mechanism of this gas spring is attached to the top of the seat base, and from the bottom it is attached to the crosspiece. The lift height will depend on the dimensions of the pneumatic chuck. Usually its length ranges from 13-16 centimeters.

It should be noted that the gas lift has 3 functions.

- Damping the shock load on the spine. The point is that when a person sits down in a chair, the mechanism works like a shock absorber, springing the seat and significantly reducing the load on the spine. Thanks to these properties, the chairs become much more comfortable and easier to use. That is, you can quickly sit down and get up without fear that back problems may appear.

- Seat adjustment. Using a pneumatic chuck, you can raise or lower the chair in a few seconds without any serious effort. It is enough just to press the lever from below, and the structure will either fall under the weight of its mass, or rise if you stand up from it, which will reduce the resistance.

- The possibility of circular rotation of the chair. This allows you to freely access everything that is located at a distance of up to 50 centimeters and turn where necessary, if necessary. The special mechanism is made in such a way that you can rotate around its axis without any problems.

In fact, the gas lift is a special hydraulic cylinder designed specifically for office chairs.

Device and principle of operation

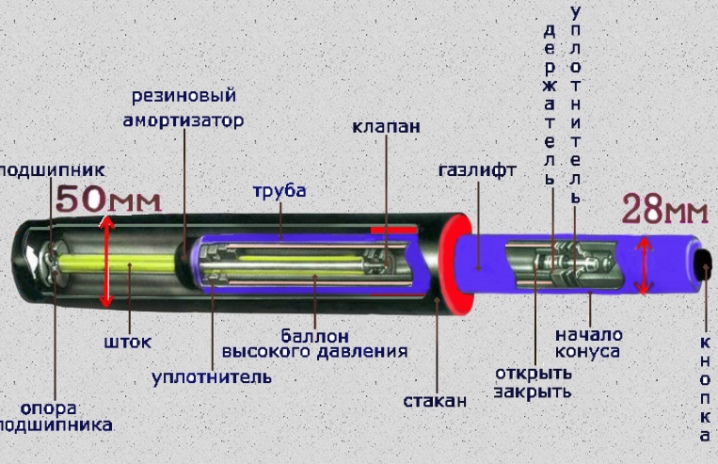

If we talk about the device of the part in question, then it should be said that the main parts of this design are such elements.

- Button. By pressing it, the valve closes and opens, which releases gas from one chamber to another, which allows you to adjust the height of the entire structure. Pressing occurs using a lever located under the seat of the chair. Although sometimes it can be located elsewhere.

- Lift rod. This part extends or falls into the body, depending on the increase or decrease in the height of the seat. By the way, this part is especially durable, because the mass of a seated person exerts the greatest pressure on him.

- Various types of seals and bushings. They are needed for high-quality connection of various parts and for sealing cavities where gas is usually located.

- Gas valve. This part holds the entire mechanism in position and opens when the seat height needs to be changed.

- External and internal cavities, as well as the bypass. Due to the movement of gas through these parts of the mechanism, the height is regulated.

- Support bearing. It is located at the bottom and is responsible for the free rotation of the chair in different directions. The strength of this type of connection is its simplicity, which ensures its durability.

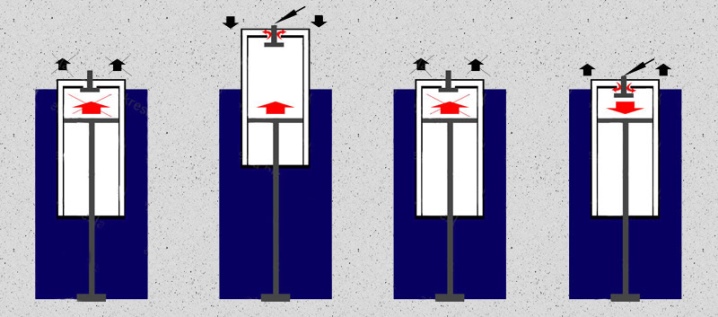

If we talk about the principle of the gas lift, then it cannot be called complicated. Let's begin with that the mechanism consists of a pair of reservoirs and a valve that can be opened and closed. It is his work that causes the gas to move along the bypass channel between the tanks. If the seat is in the down position, the piston will be in the maximum raised position. When you press the lever, the valve opens, the gas begins to move into another reservoir and thereby pushes the piston, which moves down and raises the chair.

Once the chair is at the desired level, you just need to release the lever to lock it. The valve will immediately close and the chair will be in the desired position. If you need to lower the chair, then you just need to press the lever, after which it will lower under the weight of the person's mass. That is, to raise the chair, you need to stand up from it. As you can see, the principle of the gas lift is extremely simple.

Types and sizes

There are various types of gas lifts, which is why in order to select the correct option, you should know the various models of mechanisms, and what is special about them. Usually they are all made of the highest quality steel. Usually gas lifts are divided into classes depending on the thickness. There are 4 of them.

- A feature of the models that belong to the first is that the thickness of the steel here is only 1.2 millimeters. These are the cheapest devices;

- In the second group, the thickness of the steel will be slightly more - 1.5 millimeters;

- The third group will already have a steel thickness of 2 millimeters. Such gas lifts can withstand a load of up to 120 kilograms.

- The last group is made up of the most durable devices, where the steel thickness is 2.5 millimeters. Such a reinforced gas lift can withstand 30 kilograms more than models from the third group.

In addition, the considered devices may differ in the diameter of the case. They can be of 2 types.

- 38 mm. This option is not used very often. It is usually used in executive chairs where the cross is too high.

- 50 millimeters. Used in 90% of seats.

Another important parameter will be the length of the mechanism in question. The range of height settings will depend on it.

There are the following groups of gas lifts for this criterion.

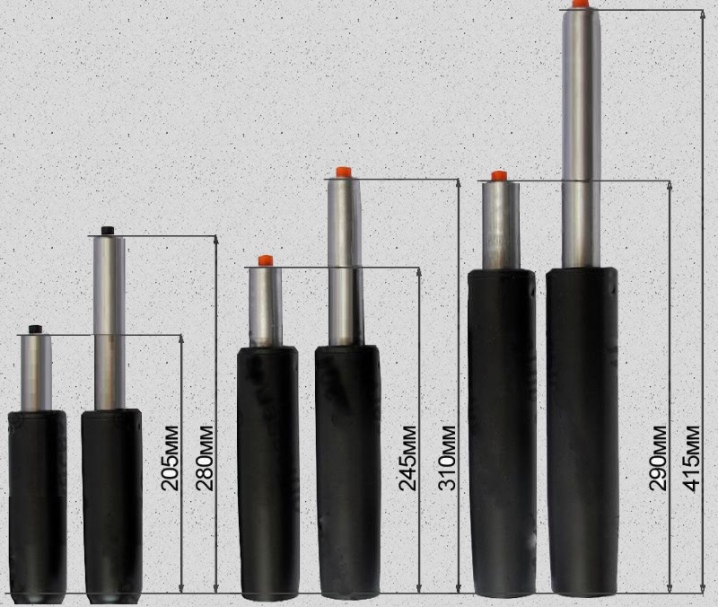

- From 20.5 to 28 centimeters. This version will be used in relatively affordable office products designed for seating at tables with standard characteristics. Such a gas lift will be short due to the fact that its adjustment range is extremely small.

- From 245 to 310 millimeters. Such gas lifts are used in places where the structure must be raised higher. Although the length of the device is longer, the tuning range here will be even less than that of the aforementioned analogue.

- From 290 to 415 millimeters. These are the longest mechanisms that have ample opportunities in terms of adjusting the height, which makes it possible to greatly change the position.

These groups of gas lifts are considered the main ones, although other models can be found on the market. For example 180 mm. But they are used quite infrequently, which is why they are more an exception to the rule.

How to choose

Given that there are different categories of gas lifts, and this is a part that breaks down from time to time, it will not be superfluous to consider how to choose the right gas lift. To begin with, it should be said that the reason for the breakdowns of gas lifts, because of which they have to be changed, are the following points.

- Manufacturing defects. This problem is rather an exception, but it still occurs, especially in the most available versions.

- Gas lift overload. It so happens that a structure that is intended for one mass is used by people whose weight exceeds this indicator, due to which the wear of the component parts occurs at an accelerated pace.

- Improper use. It so happens that a furniture or any other gas lift can fail due to the fact that a person sits abruptly in a chair or even does it at a run. Such use of the chair is fraught with simple squeezing out of the valve.

In such cases, replacement of the gas lift is required. But in order to implement it, you need to choose the right one. This is extremely important, because a discrepancy in certain characteristics can lead to accelerated wear of the new device and its subsequent breakdown. To prevent this from happening, you should make a choice based on such moments.

- Cup holder diameter. It can be of 2 types, therefore, according to this criterion, it will be easy to determine the desired option.

- Gas lift height. In this case, it is required to measure the length, taking into account that the part will be located inside the cross.

- Product dimensions. Note that gas lifts are made with different dimensions, so the size must be taken into account when choosing.

- Maximum load. It is necessary to select the class of the mechanism depending on the mass that it will have to withstand during use. Moreover, it should be taken into account that other people can use the chair.

How to change

As it was said, if the gas lift breaks down, it is almost impossible to repair it, which means that it needs to be replaced. To do this, you first need to prepare certain tools and understand the algorithm of actions. You will need to have the following things on hand:

- a new gas lift to replace the old one;

- crosshead screwdriver;

- hammer;

- annular drift;

- liquid WD-40;

- vice.

So, before replacing the gas lift with a new one, you need to remove the old one.

For this we process the joints of the parts of the chair with WD-40 liquid... We leave the structure in this state for about 12 hours so that the mixture gets on the joints. Now you need to start disassembling the chair and disconnect the seat. This requires a Phillips screwdriver. With its help, we loosen the bolts that fix the seat to the piastre. After that, we turn the chair over and dismantle the seat together with a decorative cover, which is located on the lift.

Now you need to disconnect the lift from the crosspiece and piastre. This can be done by knocking out the gas lift with a rubber-tipped hammer. To speed up this process, you can use a drift. Before starting work, remove the special retaining ring from the cross. This is a check, which is located on the back of the cross, where the pneumatic chuck is attached.

Now it is necessary to remove the pneumatic cartridge from the piastre. This work should be done as carefully as possible so as not to deform the connections. Hammering should be done in different places so that the gas lift can be carefully reached.

It is only necessary to install a new gas cartridge.

First, we insert it into the crosspiece until it clicks, applying some effort, and put on a protective casing, after which we connect everything to the piastra. All that remains is to assemble the chair in the reverse order.

The video below tells you how to choose the right gas lift for your chair.

The comment was sent successfully.