All about boiler room dispatching

The presence of a dispatching system is an important condition for the smooth functioning of boiler houses. By automating the processes and establishing remote control over them, you can not only monitor the status of devices, but also quickly respond to emergencies.

What it is?

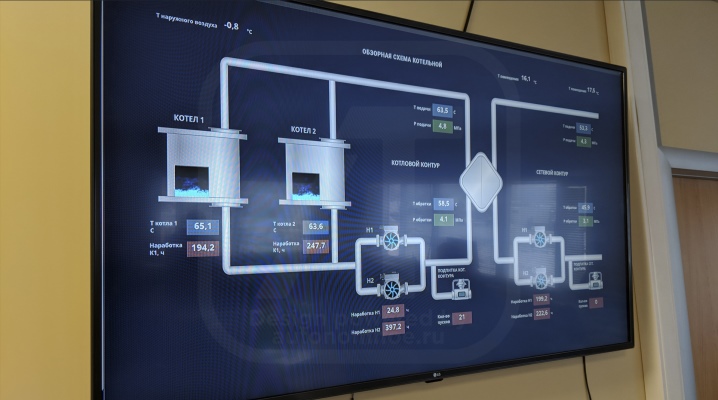

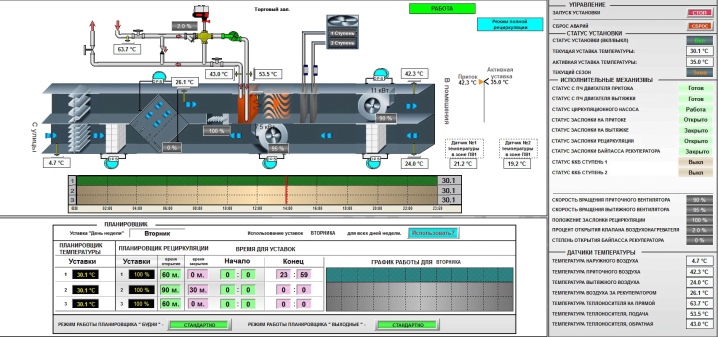

Boiler room dispatching is a remote access system that allows monitoring and adjusting their work. Particular attention is paid to the control of the parameters of the coolant. The automation of installations is carried out in two main ways: either by means of a computer or by means of a mobile connection. In the first case, the automated system is under the control of an operator located at a remote site and having access to a PC. On the screen, this specialist can observe the indicators of all parameters of the boiler room, combined on one mnemonic diagram - a dynamic picture.

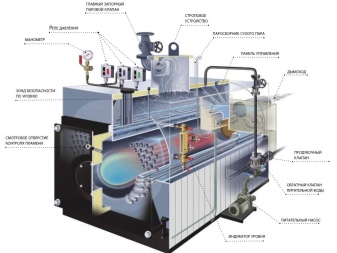

This image replicates the current thermal layout of the monitored room. This means that all available boilers, burners, pipelines, as well as actuators: pumps and three-way valves are indicated on it in the form of pictures.

Also, by means of a PC, the operator can quickly receive information about accidents. The second method of automation involves the use of SMS messages. It is he who is most often chosen to ensure the safety of a private house.

SMS messages can only come in emergency situations, when an accident has occurred, and contain a description of what happened. In the second case, the functional system simply informs at regular intervals about the monitored parameters. Typically, the operator receives information regarding the system water pressure, pump operation, return temperature, flow temperature and other important indicators.

To organize the dispatching of a boiler house by means of mobile communication, a programmable logic controller (PLC), a modem and a telephone are required to receive SMS messages. Dispatching using a computer will cost a much larger amount: an additional personal computer, the necessary software, as well as payment for the operator's work are required. Nevertheless, such a system is much more convenient and informative, especially if several boiler houses are controlled.

Computer automation allows you to save the archive of the parameters of boiler rooms and emergencies, as well as promptly respond to the loss of communication with the devices of the boiler room.

One of the main requirements for a remote access system is a stable connection without interruptions with the provision of a fixed IP address. It is necessary to understand that even in the case of an SMS notification, the loss of connection can be catastrophic, because the user will not even know that the modem simply does not receive a response from any device. In addition, it is extremely important that the design, installation and service organization has professionalism and sufficient experience. How the program will be drawn up will determine how long the boiler house will be able to operate normally without accidents.

It is worth adding that any types of boiler rooms can be automated. For example, it can be a gas boiler house that operates thanks to natural and other gases.Steam boilers that use steam as heat energy to supply industrial facilities are also being automated. And, of course, we must not forget about the coal-fired boiler house, which converts heat energy that occurs during the combustion of coal.

Main problems

The main problem facing the enterprise, which intends to conduct dispatching of the boiler house, is the need to carry out a deep modernization of technological equipment and organize an automation system based on a PLC, which costs large sums. Besides, certain difficulties are to be expected in the course of personnel reorganization. If until the moment of dispatching the boiler house had “on duty” personnel and additional operational and repair personnel, then the need for both departments disappears altogether.

As a rule, instead of them, from a smaller number of people, an operational field team is organized, which from time to time leaves for the boiler room for routine inspection and preventive maintenance.

By receiving information on the state of the object on a regular basis, it is possible to prevent any emergencies altogether. As mentioned above, the complexity of the remote control system can be an unreliable connection and the lack of a stable connection necessary for successful data transfer. Since this aspect depends on the local provider, the organization that owns the boiler room will not be able to independently resolve this issue.

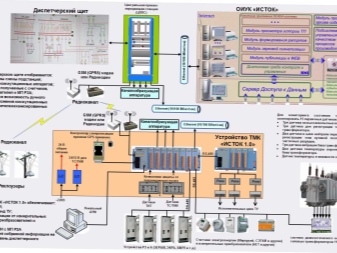

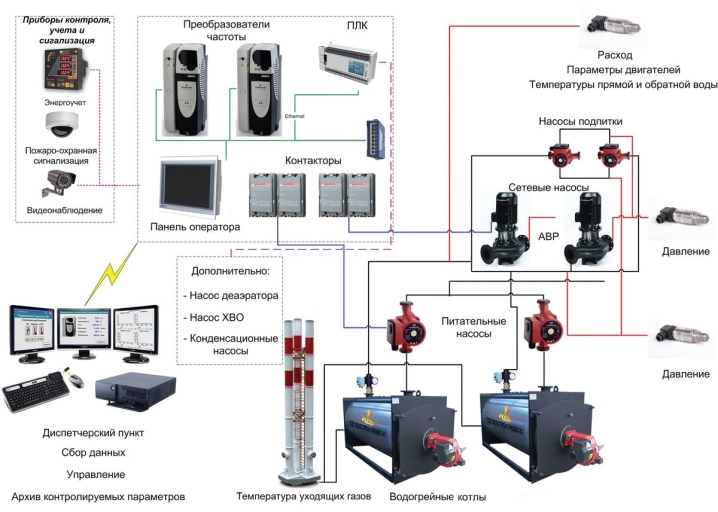

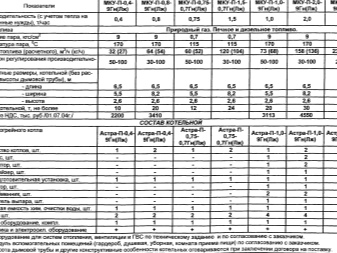

Funds overview

An integral part of the boiler room dispatching system is the automation means of the devices located in it, which allow it to function without permanent maintenance personnel on the basis of a PLC. The controller itself implements algorithms for automated process control and data exchange with the dispatching system. Also, this device is able to take into account energy resources.

The PLC operating algorithm is determined by the user himself during the programming of the device using special software. If you look at the functions performed by the PLC, you can see that it measures and digitizes the signals that come from the sensors of the devices. Typically, these include voltage, frequency, resistance, pulse duration and amperage when it comes to a steam boiler room.

The same controller also generates feedback signals that allow influencing the ongoing technological process. This happens on the basis of an algorithm generated by the operator.

In addition, the controller controls the local automatic systems of the equipment, provides data exchange and displays information on a personal computer monitor.

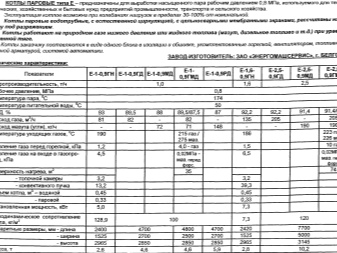

Further means should be considered using the example of a steam boiler room. All existing boilers are equipped with sensors and automatic control devices to ensure the safe operation of the burners. In emergency situations, the controller gives a signal and the fuel supply to the boilers is cut off.

Usually, This happens if the water temperature rises above the permissible value, the air pressure in front of the burner decreases, the gas or water pressure changes, respectively, in front of the burner or at the outlet of the boiler. Emergency situations also include emergency extinguishing of the burner torch and malfunctions of the protective system. As a rule, in the automated system of the boiler room there are protective means and alarms.

Usually, a quick-acting shut-off valve is mounted on the gas pipeline, which automatically closes in a number of cases, for example, if the power supply is lost. This valve does not open remotely, but only from inside the boiler room, after the accident has been eliminated. The alarm is also automatically triggered in a number of cases, after which the light signals in the room are turned on.

With regard to direct dispatching, the controller that "collected" all the necessary information - that is, the operating mode and malfunction signals, transmits it via the Internet to a dispatch center located remotely. It is also possible to send data by SMS message using a modem to the operator's phone. As for the control, in the case of a steam boiler room, the operating mode of the boiler burner, mixing pump and network pumps is displayed on the screen of a mobile or computer.

The operator can also control the current flow temperature, return temperature at the inlet and outlet of the coolant to the boiler, as well as outside temperature.

Information about the pressure comes with regards to the level at the inlet and outlet of the coolant on the boiler, supply and return, as well as the level of the coolant before and after the network pumps. Typically, the operator also receives information about the readings of electricity meters and SPT.

Alarms, about which the controller necessarily sends information, include gas contamination of the first and second thresholds, fire, opening of the room, change in coolant pressure, disruption of the make-up system, as well as opening or closing of the fuel valve. The operator can also receive information that the boiler, burner or pumps are faulty, or that the power supply to the inputs has disappeared.

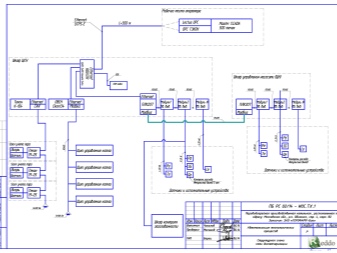

Carrying out

Dispatching always follows the same algorithm. First, all documents are worked out: installation and schematic diagrams, communication lines, instructions, a plan for laying cables and working drawings. This stage can be dealt with by employees of the engineering department of the enterprise that owns the boiler house, however, the necessary automation of the equipment is carried out by specialized firms. Upon completion of construction and commissioning work, a special commission must accept the control room and the equipment connected to it.

Before that, by the way, the controller algorithm must already be configured. Acceptance tests are mandatory before commissioning.

Thus, qIn order to organize your own dispatching system, you will need to spend money on measuring equipment - metering devices and software, communication equipment - devices for organizing communication, as well as the cost of a communication channel, including spending on fiber and its installation, as well as the purchase of Internet traffic. In addition, a personal computer and a server are purchased if necessary. During the operation of the dispatch system, it will be necessary to pay salaries to the operator, as well as compensate for the costs of maintaining the dispatch networks. To optimize costs, the owner of the boiler house will need to find a provider offering dispatching services.

Perspectives

In the future, dispatching of boiler houses in Russia will finally move away from the use of SMS messages and own communication channels, and will be carried out only through a provider's Internet connection. Moreover, processing and analysis functions will be implemented in a single information base, which will increase the number of users and reduce the cost of the system itself. Thus, the user will only need to purchase measuring instruments and then pay for the provider's services. Already he will connect the existing devices to the system and will control the transfer of information. This technology, which is actively used abroad, will save on initial expenses and organize dispatching even for small organizations.

See below for boiler room dispatching.

The comment was sent successfully.