Boiler rooms in a private house

Boiler rooms are needed in a private house. But in order to do everything right, it is necessary to take into account the basic requirements for gas boiler houses, the scheme and norms of the area of the room for gas boilers according to SNiPs. You will also have to pay attention to the main types of buildings.

Peculiarities

Not just a disadvantage, but a direct and formidable danger is that a boiler room in a private house can be a source of carbon monoxide. Of course, all the necessary structural and performance measures are taken, automatic protection devices are used, but it is impossible to give a full guarantee. If you place the boiler room in a separate building (which, by the way, is recommended), the total cost of the work will be very high. Not all people can pay the required amount.

Maintaining the entire complex in a working form is also not as easy and cheap as it seems at first. You will have to call specialists more often than you would like. Not all problems can be fixed with your own hands. However, it is worth noting the advantages, due to which there was a massive hobby for home boiler rooms:

- autonomy in relation to monopoly thermal companies;

- reduction of heat losses (even with the ideal condition of heating mains, which is rare, on average, losses amount to 30% of the initially generated heat);

- easy adjustment is provided (depending on the weather, even on the state of health and well-being).

What documents are required?

You can't just build a boiler room in a private house - you will need to issue quite a few special permits. A state examination is required. All design materials, including the results of engineering surveys, are subject to it. The end result is a conclusion about the compliance or non-compliance of the project with the regulations. Official permission became a prerequisite back in 1997, since then there has been a division by hazard classes. Without a permitting act, it is impossible to put into operation boiler houses that:

- use natural or liquefied gas;

- generate not only heat, but also hot water;

- contain at least some parts of equipment designed for temperatures above 250 °;

- contain at least some parts of equipment designed for pressures above 1.6 MPa.

Commissioning is formalized by an appropriate act. It is invalid if there are no signatures of all members of the technical commission and an employee of Rostekhnadzor.

It is allowed to build and operate boiler houses if the land belongs by right of ownership. In extreme cases, the construction of heat-generating systems is allowed on plots rented for a long time.

The technical certificates for the equipment used must be registered with the technical supervision authorities (which is also confirmed by the marks on them). The package of documents together with the application goes to the territorial inspectorate, and after the on-site check, the license is handed over.

Primary requirements

There are a number of requirements for boiler houses.

Towards safety

When decorating a boiler room, many provisions refer to the room where the necessary equipment is located. Boilers and other appliances should be kept separate from the house and from other living spaces. Since any type of fuel, including electric heating, potentially entails certain dangers, such norms cannot be called bureaucratic arbitrariness. It is necessary to carefully check which specific standard is valid in a particular case. Boiler houses built before July 1, 2003 must comply with the provisions of SNiP 2.04.08-87. Everything that is built or put into operation after this date is subject to SNiP 42-01-2002.

The main points of the standard must be known by the customer himself - after all, he needs to control whether the project is of high quality, whether the engineers of a specialized organization have competently approached their work. The purchased equipment is also immediately checked against the established design standards. So, the minimum area for a gas boiler according to the project is normalized, but in addition it is clearly defined that:

- with a thermal power of no more than 60 kW, you can place the device in the kitchen (if enhanced ventilation is organized);

- with a thermal power of 61 to 149 kW, a separate room is required (it is allowed to choose basements and basements);

- when generating 150 kW of heat and above, a strictly separate building will be required.

As for the total volume of home boiler rooms, it is as follows:

- when generating no more than 29 kW of heat - from 7.5 m 3;

- when generating 30-59 kW - not less than 13.5 m 3;

- when receiving 60-200 kW of heat or more, it is required to create a room with a volume of 15 m 3 or more.

Important: for a gas boiler, unlike other heat sources, in any case, the minimum volume of a room should be 15 3, while the height of the walls (in any part of the building) is not allowed less than 2.5 m.

All boiler rooms in private homes should have the maximum natural light possible. The glazing area is rigidly fixed in the standards: for 1 m 3 of the internal volume of the boiler room, at least 0.03 m 2 of glass must be provided (excluding the frame and other structures). In any case, only hinged, outward-opening windows are installed. It is impossible to use the boiler room without water supply and organization of sewage.

There is often a statement that it is not safe to build a boiler room in a wooden (both frame and log-built) house. This is motivated by some extreme fire hazard of such buildings. In fact, the risk has long been almost absent - it is eliminated by both special wood processing and special constructive, technological solutions. In addition, there are still a lot of combustible materials in stone, brick, and aerated concrete boiler rooms. The boiler must be provided with unimpeded uninterrupted access.

The junction of the chimney and all wooden structures must be carried out with a fire break. At the same time, asbestos and other protective substances that prevent fire are necessarily used. All wooden walls must be shielded. But even such requirements are not enough - it is also necessary to provide for a comprehensive fire extinguishing and warning system. Its installation should be carried out by professionals, who should also be entrusted with periodic inspections.

The race for beautiful design must also be kept in strict compliance with safety requirements. So, finishing with plasterboard is allowed, provided that it is subsequently coated with plaster and / or water-based paints. Tiles or metal sheets are placed on the floor. They should be painted with durable, high temperature resistant paint. Instead of drywall, the walls can be decorated with cement-bonded and acid-fiber blocks.

All wall structures, including finishes, must be designed to withstand fire for at least 45 minutes. If this figure reaches at least 60 minutes, it will be even better.

Plastering the walls is possible only with compositions that are safe in terms of fire. All fire-resistant plaster mixes are gray in color. Additionally, they can be decorated with heat-resistant water-based paints. The choice between wood, plastic and aluminum window structures is at the discretion of the owner.However, it should be understood that when PVC burns, toxic substances appear.

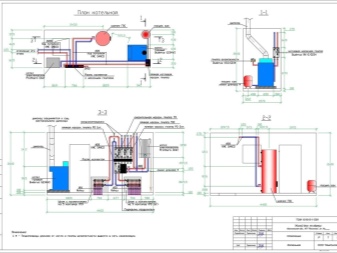

In no case should the layout of the boiler room be arbitrary, there are very clear and unambiguous rules. So, boilers, buffer tanks and other heating equipment are installed strictly as prescribed by the manufacturer. Wall-mounted heat generators hang up to a maximum height of 1.5-1.8 m (if it is larger, it is inconvenient and unsafe to use the equipment). There must be at least 1 m of free space in front of the front sides of the heating devices. The recommended gap between their walls and the main walls or adjacent objects is 0.03 m. In any case, you will have to mark the location on the plan:

- the boilers themselves;

- chimneys;

- external leads (pipes);

- radiators;

- expansion tanks;

- connecting pipelines;

- valves;

- bypasses;

- cranes Mayevsky and other parts.

A separate topic is the safety of boiler houses that do not use gas fuel. It is still recommended to form them according to the strictest standards possible. The grounding of the casings of electric boilers and wires must comply with the PUE. Everything should be connected so that there are no mechanical loads on the wires and contacts. For solid fuel systems, the following are recommended:

- installation of the inverter in conjunction with batteries (providing uninterrupted power supply);

- the use of heat accumulators;

- combination of inverters and heat accumulators.

To ventilation

In addition to the main ventilation capacities, it is necessary to provide for a window or a transom in the window. It will provide emergency ventilation in the event of a gas leak or other fuel spill, if it is contaminated with carbon monoxide. The inflow of air is calculated taking into account the information about its movement, obtained through the use of an anemometer. The total inflow value according to the current joint venture must be at least the volume of a single hourly flow. You can get the necessary information from the gas supervision specialists in your region.

Ventilation in boiler rooms is always done strictly according to official projects.

It is imperative to achieve the tightness of the ventilation ducts, as necessary - use a sealant. Air pumping can take place both outside and inside the building. But it is impossible to supply combustion air through the living room. Natural ventilation is only suitable for boilers not exceeding 30 kW, otherwise fans are required.

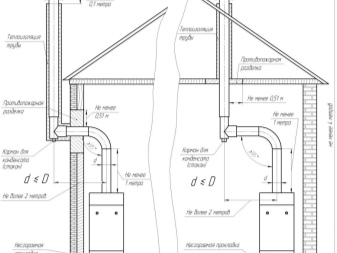

To the chimney

The flue duct can be round or rectangular. The connection to the chimneys is made using roofing steel pipes or the elements supplied in the kit. All parts of the chimney outside the building need to be insulated. The section and height of the structure are carefully selected in accordance with the parameters of the boiler. Other requirements:

- each boiler must have its own chimney;

- they should not have umbrellas and reflectors;

- a hole for cleaning is placed between the boiler and the connecting pipe;

- pipes are raised above the tallest building in the area.

Description of species

There are several types of boiler rooms.

Built into the house

This type of boiler room is appropriate both in the basements of one-story houses and on their first floors. The main disadvantage is the lack of security. In addition, many boilers are very noisy. To some extent, this is justified by the convenience of using boiler equipment. Most often, built-in complexes are located in kitchens and corridors. There must certainly be a separate exit to the outside and a number of fireproof partitions.

In the annex

A boiler room attached to a residential building (located, for example, in a garage) will suit those who do not need a particularly high power. The boiler room will be cozy and save money. The door will have to be upholstered with sheet metal and / or asbestos. In the vicinity of residential premises, additional noise insulation is carried out. It is not prescribed by the standards, but it is needed.

There must always be an exit from the attached boiler room. In some cases, the presence of a passage to the house itself is not allowed. Only experienced engineers can understand these limitations. The thermal power of the equipment should not be selected with a margin, but only in full accordance with the needs of the residents. The regulations apply not only to heating equipment, but also to the methods of heating the building itself from its extension.

Detached building

They try to bring such buildings as close as possible to residential buildings. A variety of technical communications are used to communicate between them. In separate boiler rooms it will be possible to place any heating boilers, to use any type of fuel. The use of boilers of almost unlimited power is allowed. Heating mains are used to supply heat to the dwelling.

Block-modular

This option is optimal when it is impossible to put a boiler room inside the house, it will not work to build a separate building. Such structures are assembled from factory components and assembled fairly quickly. The length of the special container is maximum 2.5 m. The steel structure is insulated inside. The delivery set usually includes multilayer heat-insulated pipes. Block-modular boiler rooms can be powered by:

- liquefied gas;

- coal;

- diesel fuel;

- firewood;

- natural gas.

Item overview

The heating boiler is a key element in the arrangement of the boiler room.

If you plan to waste water for domestic needs, you will have to install a boiler.

This device is very bulky, and if there is no need for it, it is impractical to buy such a device. But the expansion tank, which allows you to equalize the pressure, is very useful. In addition, in heating systems with a large number of circuits, a distribution manifold must be present. In addition to these elements and a chimney, you definitely need:

- circulation pump;

- security group;

- a set of pipes with locking fittings;

- automatic gas contamination control.

Installation tips

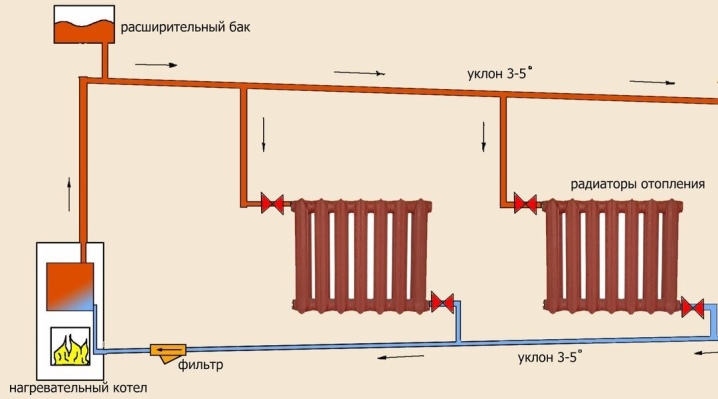

The heating device scheme in each private house is individual - and yet there are clear principles and criteria that are more or less universal. The procedure for strapping heating and hot water supply boilers with your own hands implies, first of all, dividing into open and closed groups. In the open version, the boiler is placed below all other components. The expansion tank is raised as high as possible: it is the height difference between them that determines the overall efficiency of the entire equipment.

An open circuit is the easiest to prepare. In addition, it is non-volatile, which is very important for remote locations and for areas with frequent power outages. But one must understand that continuous contact of the coolant with atmospheric air inevitably leads to clogging with air bubbles. The coolant will circulate slowly, and it is impossible to accelerate its flow due to design schemes. If these points are fundamental, and if there is a desire to also reduce the flow rate of the coolant, it would be more correct to make heating according to a closed circuit.

If the boiler room is located in an extension, then it must adjoin a solid section of the wall. In this case, at least 1 m of free space should be left to the nearest window or door. The building itself is made of fire-resistant material with guaranteed resistance to combustion for at least 45 minutes. Wall-mounted boilers are mounted only on walls made of non-combustible materials. Carefully observe that there is at least 0.1 m to all other walls.

The best screen for the boiler is a stainless steel sheet, under which asbestos is still placed.

If powerful (200 kW and more) boilers are used, it is imperative to prepare a separate foundation for them. The difference between the height of this foundation and the height of the floor cannot exceed 0.15 m.When it is planned to use gas fuel, they provide for the installation of an apparatus on the pipe that urgently turns off the gas in a critical situation. Furnace rooms are equipped with unreinforced or weakly reinforced doors: when they explode, they are thrown out, and this reduces the risk of destruction of the entire building.

When a boiler room is installed, built into the house itself, it is allowed to install thoroughly reinforced doors. However, another requirement is presented to them: to restrain the fire for at least ¼ hour. To improve ventilation, in any case, a hole is made in the lower third of the door, closed by a mesh. The entire volume of the walls is trimmed from the inside with fireproof materials. This must be done as soon as the installation of the boiler and its connection to communications are completed.

It is absolutely unacceptable to mount boilers more powerful than 60 kW on the wall.

The number of contours is also important. If you plan to limit yourself to heating, it is quite reasonable to choose a single-circuit boiler. For your information: it can also be used for hot water supply, but only in conjunction with a boiler. The installation of the boiler is justified under 2 conditions: a lot of hot water is consumed and there is a lot of free space. Otherwise, it would be more correct to order a double-circuit boiler.

Ventilation communications are installed in the wall opposite to the boiler. A mesh and a damper are necessarily mounted in the ventilation pipe. In boiler rooms located in a separate room, you will have to make a ventilation duct in the door with a louvered grill.

For each kilowatt of thermal power, there should be 8 cm 3 of the volume of the ventilation passage. But if the air comes from inside the house, this figure is 30 cm 3.

An overview of a boiler room on gas equipment for a private house in the video below.

The comment was sent successfully.