Dimensions of the boiler room in a private house

There are two ways to heat a private house - centrally and individually. Today, many owners are leaning towards the second option. To heat a house on your own, you will need special equipment and a room in which it will be located. Gas and other fuels can create hazardous situations if misused. To avoid them, certain technical rules for the arrangement of boiler rooms have been developed, they also apply to the size of the room.

Primary requirements

The room for installing the boiler is called a boiler room, boiler room or furnace. It is necessary to take care of it even during the construction of the house, otherwise in the future you will have to find a suitable area for installing the boiler. Depending on the capabilities of the house, the furnace has a different location - on the ground floor area, equipped in the basement room or built directly next to the building. The following factors affect the requirements for finishing and arrangement of the room:

- the location of the boiler room;

- number of boilers;

- their volume;

- types of fuel used.

Consider the general standards for the maintenance of all types of private boilers, and in the future we will talk about the rules for arranging boilers for different types of fuel. When containing flammable materials, it is important to ensure the room is safe from possible fires; strict requirements have been developed for this.

- Walls and floors must be protected from fire, they are poured with concrete or tiled.

- Additionally, the floor can be sheathed with aluminum sheets, but this is an optional item, a concrete base is enough.

- The door is made of fire-resistant materials, especially if the furnace is located in the house itself.

- The room needs natural light. The calculation of the glazing of the window depends on the volume of the room - by 1 cubic meter. m 0.03 sq. m of glass.

- For the boiler room, the ventilation system is well calculated and implemented.

- There can be no more than 2 boilers in the room at the same time.

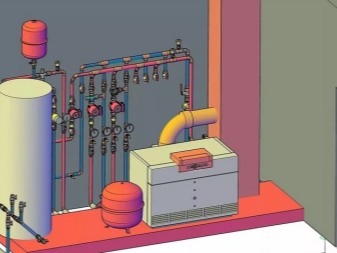

- It is important to provide free access to equipment maintenance and repair.

- It may be necessary to supply a sewage system to drain waste water and condensate.

- The minimum parameters of the combustion room are 7.5 cubic meters. m.

- The allowed height is 2.5 m.

A few more requirements are added to the furnace, located not in a residential building, but in a detached one.

- It should be built from materials that are not subject to combustion - cinder block, aerated concrete, expanded clay concrete, brick.

- The extension is carried out on an individual foundation and has its own walls that are not connected to the house, even if they come close to the building.

- The boiler room should not be closer than 100 cm from the front door of the house or from the windows of living rooms.

Standards for a gas boiler room

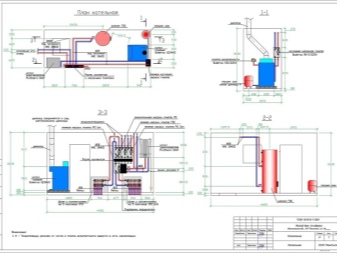

Before you start equipping a home gas boiler room, you should understand the regulatory framework. Recommendations and requirements for its construction are set out in the materials of SNiP 42-01-2002 dated 1.07.2003. The plan of the combustion room is developed with the design department of the Managing Gas Company, all controversial issues should be discussed with them.

The size of the boiler room depends on its location and the power of the boilers, in most cases both of these factors are interrelated.

Arrangement of boiler rooms based on the power of the boiler

The more powerful the boiler, the more room it will need. When arranging a boiler room, the following standard indicators must be taken into account.

- Boiler up to 30 kW can be located in a room of minimum size - 7.3 cubic meters. m with a ceiling height of 2.1 m. A kitchen, bathroom or corridor is quite suitable.

- Boiler from 30 to 60 kW can also be placed in the kitchen, but the minimum volume of the room must be at least 12.5 cubic meters. m, and in height - 2.5 m.

- Boilers from 60 to 150 kW a separate room is required. In rooms below the level of the 1st floor, to the optimal 15.1 cubic meters. m, an area of 0.2 sq. is added. m per 1 kW of power. At the same time, the walls of the room are protected by a coating from steam and gas formation. The use of liquefied gas in the basement is prohibited, for this type of fuel you will need a room on the first floor of the building or in a separate annex with a ceiling height of more than 2.5 m.

- Boilers from 155 to 355 kW can be located in a separate building or below the 1st floor. But wherever the furnace with equipment of such power is located, it must have its own exit to the courtyard.

Additional requirements

In addition to the above standards, other rules are taken into account when equipping a home boiler room.

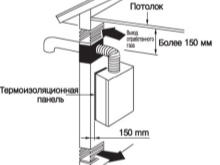

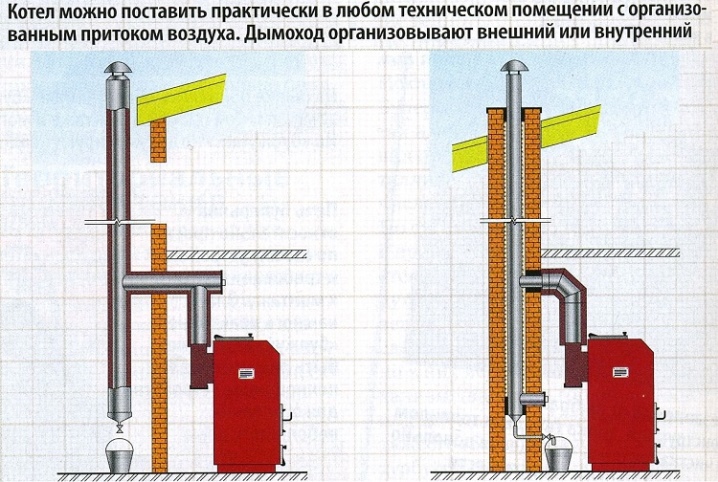

- The optimal way to remove combustion products is being thought out in the furnace. If the boiler has a power of more than 30 kW, the room will have to be equipped with a chimney that goes beyond the roof level. For low-power equipment, a ventilation hole in the wall will suffice.

- The window in the room is arranged in such a way that it can be freely opened, this will help get rid of the accumulation of gas when it leaks.

- The boiler room is provided with a water supply and sewerage system. They will be required to power the equipment and remove waste heat drains.

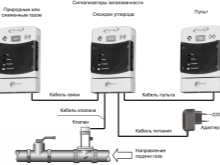

- In a boiler room with a boiler over 65 kW, a gas level control system is installed.

With the help of sensors, the system monitors the gas level in the room and timely shuts off its supply.

Dimensions for rooms with other boilers

In addition to gas equipment, there are other devices that run on electricity, solid or liquid fuels. For boilers serving different types of equipment, their own standard rules have been developed.

Liquid fuel

Boilers of this category use fuel oil, oil, diesel fuel for operation. They emit a loud noise and a specific smell. Due to these factors, it is better to place the liquid fuel boiler room in a separate building, it is possible in the garage. For convenience, you should take care of sound insulation, and supplement the metal doors with a seal, it will help to some extent to keep the noise and smell.

When calculating the parameters of the room, 4.5 square meters are taken into account. m for the installation of the boiler and a place for storing fuel. As a last resort, the fuel tank can be identified outdoors. The boiler room needs good ventilation; at the bottom of the wall there is a window with the possibility of ventilation. Liquid fuel boilers are rarely equipped due to strict fire safety requirements.

Solid fuel

Solid fuels include firewood, all kinds of eurowood, pellets, fuel briquettes, coal and peat. This entire range is not explosive and is cheaper than gas, but inferior to it in terms of comfort. In addition, such boilers have low efficiency, only 75%. The GOST requirements for a solid fuel boiler room are less stringent than for gas equipment. The room should be 8 square meters. m and be in a separate building. But sometimes it is arranged in a room below the residential level.

The wiring in the room should be hidden, it is better if it runs inside fire-resistant pipes, and has a reduced voltage (42 V) to power the outlets. Maximum tightness is applied to the equipment of the switches.

This precaution will prevent the coal dust present in the air from igniting.

For solid fuel boilers, supply and exhaust ventilation is important, the supply of fresh air makes it possible for the fuel to ignite better. The cross-section of the hood for the basement floor is calculated according to the scheme - 1 kilowatt of boiler power per 8 sq. cm. For the basement, the cross-sectional dimensions increase to 24 sq. cm per kW of power. A supply window is installed at the bottom of the wall.

The chimney should be straight, in extreme cases, have a minimum of knees. It is good if the cross-section of the pipe coincides with the diameter of the inlet, but is not narrowed by the adapter. The chimney is routed to the outside thanks to a fire-resistant material assembly installed at the outlet of the chimney through the roof or wall. Furnace rooms with solid fuel must be equipped with a fire shield and a fire extinguisher.

On electricity

Electric boilers are the safest and most comfortable. But before deciding to install them, you should weigh the pros and cons, each of the arguments is sufficiently weighty and can affect the choice of the owner. Let's start with the positives.

- A heating boiler of this type is no more dangerous than any household electrical appliance in the house.

- It does not need a special room; a kitchen, a bathroom, a hallway are quite suitable for installation.

- There is no need to equip a special ventilation system.

- The boiler does not contain hazardous combustion products.

- Does not emit noise and odor.

- Its efficiency is close to 99%.

The main disadvantage of this type of equipment is its complete dependence on external power supply. Installation of boilers in areas with frequent power outages is impractical. For buildings with an area of about 300 sq. m you will need a boiler with a capacity of 30 kW. The heating system must be equipped with a stabilizer, safety switches. House wiring must be new and reinforced.

There is another significant disadvantage of heating a house with electricity - this is the cost of such heating, it is the highest among all known methods. Whichever type of heating system is chosen, it is necessary to follow the recommendations for its installation and operation.

In addition to the dimensions indicated by the standards, the boiler room should be increased to the level of its own convenience, which allows the equipment to be serviced and repaired without hindrance.

The comment was sent successfully.