Everything you need to know about boiler room design

Receiving heat is unthinkable these days without various boiler installations. But they must be installed in special rooms. Having found out everything there is to know about designing boiler rooms, people thereby relieve themselves of many worries and guarantee themselves a comfortable life.

What should be considered?

The basic norms for creating boiler rooms in a private house are not fixed in SNiP, which has lost its force for a long time, but in SP 89.13330.2012. However, already in the title it is noted that this is a modernized version of the building codes adopted in 1976. Formally, the document refers to the industrial segment, but no one bothers to apply the same standards in everyday life. When calculating the total consumption of heat energy, it is required to take into account the discrepancy between the peak load for each individual consumer, including in time. It is necessary to do everything so that, even in the minimum mode (summer period), the operation of the boilers is verified and free, without any difficulties.

Open installation of boiler equipment is permissible if it is designed for this by the manufacturers. You also need to pay attention to the unavoidable noise effects. The layout of all equipment and technological solutions must ensure:

- optimal level of security;

- reliability of work in a variety of conditions;

- easy maintenance of equipment and its adjustment;

- the possibility of mechanization and / or automation of a maximum of operations;

- simplified management in normal and emergency situations;

- the economic efficiency of the boiler room;

- environmental and sanitary safety of ongoing projects.

Main steps

Pre-project preparation

This stage is mandatory for any plans to create boiler houses, even for low-power facilities using a pellet fuel variety. Professionals will be able to easily calculate the real needs of objects for thermal energy. However, they will also be engaged in the selection of the fuel itself and the determination of the necessary technological parameters. It is on the information collected at this stage that the quality of the future project and its functioning in various conditions depend.

The developers are trying to foresee all at least some possible adverse factors and to think over the ways of their relief in advance.

Collecting documents

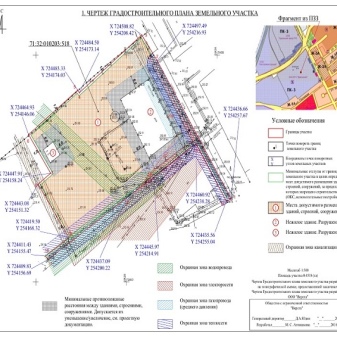

Such a technically complex work as the creation of a boiler house is unthinkable without extensive documentation. Technical specifications are being prepared in the depths of specialized organizations. The involved specialists will assess the conditions of a particular place from the point of view of engineering geology and engineering ecology. Additionally, complex engineering and geodetic surveys can be carried out. Using these materials and preliminary calculations, you can already prepare a general urban planning plan.

In this plan, the largest possible indicators are displayed that a constructed boiler house can take. That is, rational restrictions are established on its height and power, on the length and depth of laying the foundation, on the specific load on the ground, on the consumption of fuel and other resources. The stage of collecting documents ends with the formation of a project assignment. It prescribes the exact composition of the equipment used. It is also necessary to reflect in the assignment the entire set of materials that can be used.

Boiler plant design

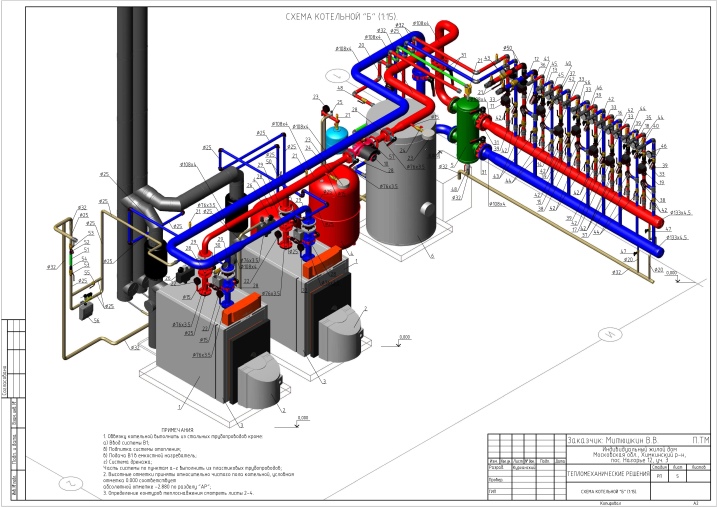

This is the third stage in order, but not in importance.At this stage, it is usually determined whether the main equipment will be located in a private house or in an annex to it. Specialists will draw up basic drawings and device layouts. It will become clear where to supply electricity and water, where fuel will be accumulated or pumped over.

During the design process, a package of documents is created, according to which it is already possible to immediately begin construction work.

Coordination and approval

No matter how good the project itself is, it is unacceptable to build a boiler house without considering it (with a positive conclusion) in government bodies. Examinations and inspections can be of a very diverse nature. Depending on the specific conditions, the study of the project can be carried out by both state and non-state expert bodies. Sometimes an industrial safety examination is provided, the correctness of the conclusions of which must be confirmed by Rostekhnadzor specialists.

Variants

If there are serious funds, people can even order a plan for a one-story house with 3 bedrooms and a boiler room with a total area of the heated space up to 100 sq. m and even more. In this case, they use both autonomous and thermal complexes serviced by city services. It is recommended for safety reasons to move the heating equipment to a separate room. In the overwhelming majority of cases, a boiler room project involves the use of two boilers - and no more. This is due to the fact that with a large number of them, it is not possible to ensure adequate safety.

The adjustment will be carried out according to the temperature schedule, due to special indicators. It is worth noting that in some cases, for permanent residence in harsh places, they still use boiler house projects with three heating units. It is then usually envisaged to use a closed heat generation circuit.

To guarantee the stability of the devices, you will have to build on typical projects.

Separately, it is worth talking about the boiler rooms used to supply heat to the baths. When it is planned to heat only the steam room, a single-circuit boiler is used. It is necessary to use double-circuit equipment if it is required to additionally supply hot water to the washing room. Another additional circuit is used to heat the floors and the indoor pool. The peculiarities of coal-fired boilers should also be taken into account.

They can be used both for cottages with a height of 2 floors and for heating showers in baths and saunas. The use of anthracite and other types of coal is most practical in areas with low gasification levels. Inside can be placed both generating steam, and heating water, and combined heat systems. Coal-fired boilers can be modular (collapsible) or completely stationary. It is imperative to reflect in the project whether the fuel supply will occur centrally or manually.

Boiler rooms for an industrial facility differ significantly from their individual type. And it's not just about the significant power of the components used. Most often in the industrial segment, natural or liquefied gas is used. The technical and economic parameters of the building under construction must be considered. Additionally, process maps are taken into account.

Returning to the design of boiler rooms for a private house, it is also necessary to point out that for them the space of the first floor is mainly allocated. If a garage is attached to the house, then it is logical to combine the boiler room with it. The transition between the two zones of the utility room takes place through the vestibule. For heating, only standard industrial equipment is used, placed according to standard designs. It is imperative to provide for the outlet of air through the ventilation ducts.

It is unacceptable to install more than 4 boilers in the garage, regardless of the area of the room. The minimum size of the garage-boiler room is 6.5 m2, the smallest permissible height is 2 m. Despite the seeming simplicity, it is required to invite specialists to connect all the equipment. In the house itself, a terrace can be re-equipped for a boiler room. The floor will definitely have to be insulated, otherwise all the work completely loses its meaning.

However, an alternative would be the execution of formwork and backfilling with expanded clay. If the boiler room borders on any cold room, it is required to provide an insulated sealed door. Sometimes an attic is used to decorate an impromptu boiler room. Any type of heating equipment is placed there, as long as the key safety requirements are met. Since the systems will not be located on the first floor, only closed-type boilers are allowed.

Recommendations

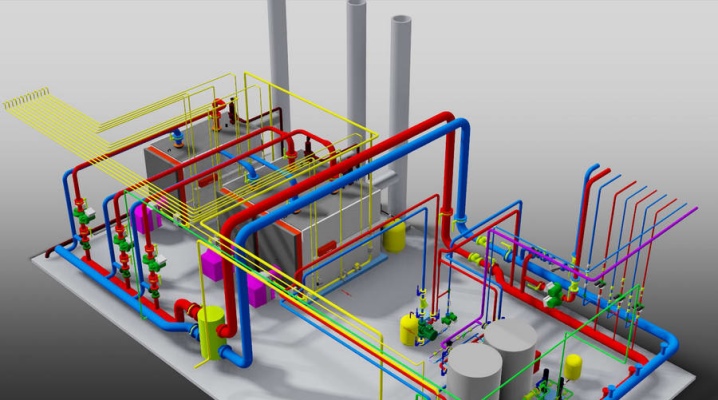

In attics and on the second floors, it is recommended to install wall-mounted gas boilers with a capacity of no more than 30 kW. This resource is quite enough to heat a small house. In the design process, it is recommended to draw up not only ordinary "sections", but also three-dimensional models. An electrical wiring diagram is also necessarily formed. The total volume of the boiler room is determined by the power of the heat source:

- up to 7.5 m3 are limited to 30 kW;

- with a size of 13.5 cubic meters. m, you can already install equipment from 30 to 60 kW;

- boilers generating 60-200 kW of heat must be installed in rooms with a capacity of at least 15 cubic meters. m.

Experts insist that all boilers using fired fuel should be equipped with air monitoring systems. It is very good if the automation can turn off a dangerous device when it detects gas contamination. All boilers with a capacity above 100 kW can only be installed with the direct permission of the supervisory authorities. For electric heat sources, permission must be obtained starting with a power of 15 kW.

Appropriate permissions must be added to the project documentation.

According to professionals, the connection of the boiler to the chimney should be carried out as straight as possible, without ledges and bends. Closed condensing boilers are installed without pipe constriction. Roof-top boiler rooms cannot be located on the very floor of the living quarters. They should not be allowed to adjoin the living space either. If the height of the building is 26.5 m, it is allowed to put the boiler room on its roof only with the approval of the fire authorities; it is much easier to provide for another solution.

The minimum level of fire resistance of parts of roof boiler rooms is at least 45 minutes. These rooms should have an exit directly to the roof. When supplying gas, it is assumed that the pressure in the gas pipeline does not exceed 5 kPa. Higher pressure can only be used in industrial heating complexes, and this must be motivated. All chimneys must rise above the back-up point.

We must not forget about the waterproofing of the floor (regardless of the specific type of boiler room). Also, do not ignore the architectural and design characteristics of the premises. Only with a balance of appearance and functionality can we say that the project is well thought out. Professionals advise using BIM technologies in the design.

A good project team will definitely include an estimate in the documentation package so that it is clear what costs to focus on.

The documentation package for a large boiler house includes:

- coordination of water use;

- document justifying the design decision;

- information on engineering surveys (according to part 47 of the town planning code);

- description of the characteristics of networks at the points of connection;

- permits related to land management and other legally regulated issues;

- documents of title to the territory and buildings.

Here are some more tips:

- reflect in the project the capacity of the fuel warehouse;

- fix the dimensions of individual racks;

- take into account heat losses for ventilation, as well as heat sources not related to heating;

- provide for the use only of equipment from major well-known suppliers;

- provide, if possible, autonomous fire extinguishing and alarm systems;

- show in the project all cross-sections of pipelines and wires.

For what you need to know about boiler room design, see the next video.

The comment was sent successfully.