Installation of boiler equipment

In order for an individually built house to be warm and comfortable, it is necessary to think over its heating system. The boiler room provides a favorable temperature regime in the house. Natural gas is most often used for heating in homes. But for the system to be reliable and safe, you need to choose the right equipment for the boiler room, install it and launch it.

Fundamental rules

Installation of boiler equipment is carried out in a specially designated room, called the boiler room. For gas boiler heating, the room must be specially prepared.

- The boiler room can be located on the ground floor of the house or in the basement. It is best if the boiler room is equipped in a special detached building.

- The territory of the boiler room should not be equipped below the living rooms of the house.

- The total volume of the room cannot be less than 15 cubic meters. m, and the height of the ceilings must be at least 3 m.

- The door to the boiler room is installed in such a way that it can only be opened to the outside.

- The main requirement for the premises is the presence of a separate and rather powerful ventilation system.

- In the event that other rooms are located near the boiler room, walls must be equipped between them and the room for gas equipment, the fire resistance of which is at least 45 minutes.

- During the operation of the equipment, gaseous waste is formed during the combustion of gas. You can get rid of smoke only by installing a separate, specially made pipe.

Such basic rules must be known and followed by every installer of a gas boiler house.

They are designed to minimize the occurrence of an emergency and prevent gas explosions, fires, toxic poisoning, and so on. Strict observance of the requirements related to the installation of equipment in the boiler room guarantees the user a long-term operation and safe operation of the gas heating system.

What is needed for installation?

Before starting the installation work related to the installation of boiler equipment, it is necessary to prepare all the necessary components.

- Gas boiler of the capacity, which is laid down in the design documentation of the boiler house. The boiler must be certified and have technical documentation.

- Prepared chimney system. The necessary equipment for it and the choice of modification directly depend on the type of boiler that will be selected for the project. There are boilers equipped with forced draft, in this case, a hole of the required diameter should be made in the wall.

- Many boiler models are pre-equipped with a circular pump, but there are also modifications in which the pump must be installed separately. Often you have to purchase 2 circular pumps at once.

- Modern boilers have a built-in expansion tank, but if it was not in your model, the tank should be purchased and installed separately. In some cases, even if the boiler has an expansion tank, it is required to buy an additional tank and install it in the heating system.

- A special distributor called a comb, the modification of which will depend on the heating project of the house.

- To de-air the heating system, you will need to purchase a special valve.

- Special equipment called a "safety group".

- Various types of gas shut-off valves provided for by the boiler house project.

- Pipes and fittings are required to distribute heating throughout the house. The material depends on the project: it can be polypropylene or metal.

- Auxiliary materials: sealants, seals.

After purchasing all the necessary components and additional materials, you can proceed to the phased installation of equipment in the gas boiler room.

Stages

The whole process of installing boiler equipment can be conditionally divided into stages. They should be performed sequentially in order to avoid a waste of time and money, which often happens if a set of works begins to be performed chaotically.

The step-by-step steps for installing gas heating are as follows.

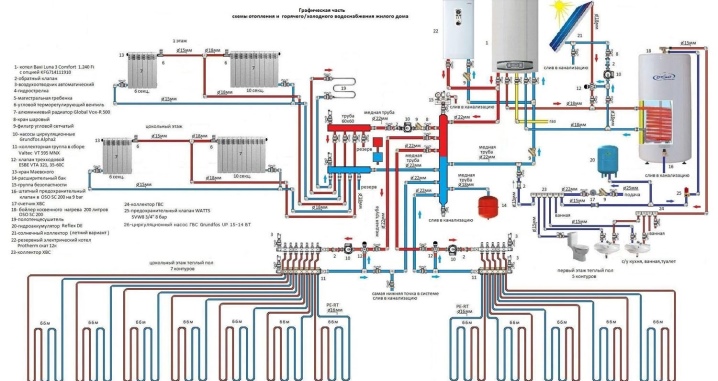

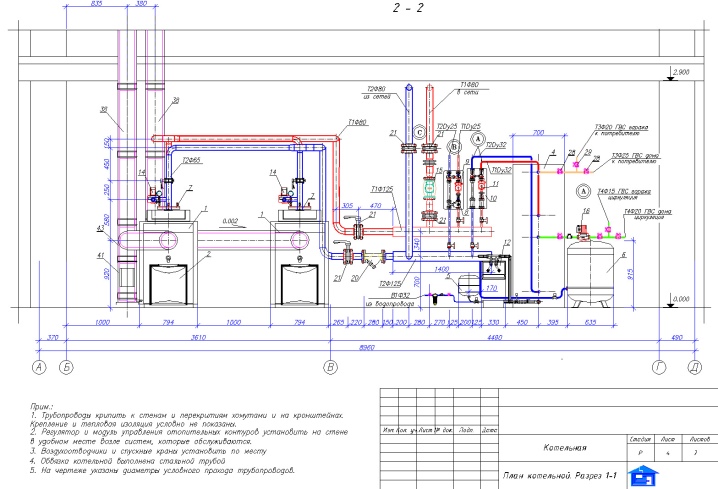

Drafting a project

After completing the preparation of the boiler room, gas specialists are called in, who will inspect the house and the boiler room, and then, taking into account the design features of the premises, draw up a project for the heating system. When the project is ready and agreed, you can proceed to the budgeting. The estimate of materials will take into account not only the modification of the boiler, but also all the necessary devices, components, as well as consumables. The project, in addition to the estimate documentation, must also contain data regarding the calculation of the boiler's power, as well as instructions on where the boiler itself, the chimney and ventilation ducts should be installed.

The main criterion for performing calculations will be the area of the boiler room and the entire house, which will be heated using a gas boiler.

The finished project will need to be approved by the supervisory authorities, as well as register it. A correctly drawn up project will allow you to avoid annoying mistakes and alterations in the future, which take not only time, but also money. After agreeing on all the important nuances and details, you can proceed to purchasing the necessary heating equipment.

Purchase of equipment

The boiler, which is installed in a private house, differs in its power from industrial equipment, although the principle of the system is the same in both cases. It is best to purchase equipment at specialized trade enterprises that can advise you on all issues and help you choose the right equipment. Today, there are professional companies on the market that not only offer boiler equipment for sale, but are also ready to perform a full cycle of installation and commissioning works, bearing responsibility for the equipment provided and for the quality of installation.

Installation

Upon completion of all preparatory work and the purchase of equipment, the installation process begins. At this stage of work, a gas boiler is mounted, then piping is laid around the house, pumping equipment is installed and a centralized control system is connected.

If desired, the boiler control can be made fully automated, which will relieve the user of manually controlling and regulating the heating process and the operation of the boiler room.

Before installing the boiler, a podium foundation is made for it. This measure is mandatory, since in the absence of a foundation, the gas pipeline system will deform, which will inevitably lead to failure of the heating equipment.

The main steps for the installation of boiler gas equipment are as follows:

- assembly of the boiler and its mounting on the foundation;

- setting up a gas pipeline system through special openings in the walls;

- installation of pipes, pumping equipment, control sensors and an automated system;

- connection of heating equipment to the mains;

- final installation of the chimney, ventilation system.

Another important point is the tightness of the gas pipeline connection. Leaking gas can cause an explosion and fire.

An equally important nuance is the process of gas supply itself: it is necessary to equip the installation with a special valve that will block or open the flow of natural gas into the boiler.

After the installation of all critical units, chimneys and ventilation systems has been completed, the heater is installed.

Launch

When the installation of the gas boiler room equipment is completed, you will need to check how well they are done. Checking the quality of the installation is as follows:

- the boiler, pipeline and all components of the automated control are inspected;

- hydraulic tests are carried out to determine the tightness of the heating system;

- a complex of commissioning works is being carried out.

When testing the operation of the heating system, the following important parameters must be checked:

- correct operation of the gas supply interlock mechanism;

- correct and reliable installation of the safety valve system;

- indicators of the characteristics of the power supply system for compliance with their design.

After completing the tests, a representative of the supervisory authorities is invited to the boiler room for the delivery and registration of boiler equipment. The organization carrying out installation work and testing gives the customer warranty documents and trains him in the techniques and rules for working with boiler equipment. Only after the user is able to properly handle the heating system, it is possible to start its full operation.

How the installation of a boiler room with a double-circuit boiler is carried out, see below.

The comment was sent successfully.