Features of the choice of the door to the boiler room

Heating houses, cottage settlements and other objects with the help of boiler rooms is a process in which there are no trifles. On the contrary, even the specifics of choosing a door to a boiler room can be very important for the correct solution of emerging problems. A wide range of fire safety requirements are imposed on these doors, and manufacturers produce them in a fairly wide range; this greatly complicates the selection process.

Peculiarities

It is quite obvious that the doors to the boiler room are not the same as the passage to a house, to a warehouse, or even to a large collective garage. After all, the presence of powerful heating equipment increases the level of danger. Almost all boiler room door structures are made of steel alloys. Strict state and departmental standards have been introduced, from the norms of which it is absolutely impossible to deviate.

However, the developers are still trying to provide both high aesthetics and ease of use; designs vary depending on the wishes of consumers.

Fire safety requirements

In the Russian Federation, unambiguous SNiP apply to all entrance structures to boiler rooms. Compliance with the norms is mandatory in all cases, even if the desired object is in a private house. No differences from the practice of work in public utilities and at industrial facilities are allowed here. The regulations relate to:

- sizes;

- materials used;

- method of opening;

- ventilation;

- designations on conventional diagrams.

The standards paint only the size in the transverse plane. The width of the door leaf should be at least 0.8 m. Excessively narrow doorways will have to be widened. It is equally important that the exit doors from the premises should open outward; opening inward is dangerous, which is understandable just for reasons of elementary logic. It should also be borne in mind that it is impossible to install sliding door structures.

Owners of personal boiler rooms with boilers with a capacity of up to 60 kW can refuse equipment for going outside. It is enough to go directly to the house. However, the controllers will definitely find out where exactly the door swings open - inward or outward. Its smallest size is 0.8 m wide, as in the previous case. Without fail, only structures made of non-combustible materials are installed in boiler rooms and boiler rooms.

Most often, steel frames are used, sheathed with sheet steel. The outside of this casing is covered with powder enamel. The thickness of the canvas is not regulated. There are also no requirements for the characteristics of insulation materials. It is allowed to use "warm" structures, including those with a multi-chamber glass unit.

However, the use of combustible insulation materials such as mineral wool is prohibited.

It doesn't matter if you need a door to the street or it leads into the house. A mandatory requirement will be the presence of a special plate. Inside the blue frame, the name "Boiler room" is written in large block letters as clearly as possible. Formally, this is not controlled, but it will be calmer for yourself. In some cases, easily reset doors are used.

The reason is very simple: in an explosion, the flying off door lowers the pressure inside the room. The force of the pressure of explosive gases on walls and other structures is reduced. This property is especially important in places with gas heating equipment.

But you need to understand that dropping the canvas from the hinges is greatly complicated with reinforced glazing.The gap at the bottom of the door must be at least 0.02 m, otherwise optimal ventilation will not be ensured.

In the process of acceptance, the compliance with SP 42-101-2003 is checked. According to this standard, a window is an obligatory element of the equipment. If the windows (and, in addition to it, the ventilation grill) are not on the walls, then it is necessary to equip the doors with them. In order to cope with the claims of inspectors, it is recommended to use light-release structures.

The windows in them must comply with the universal specifications for steel windows prescribed in GOST 23344-78.

What are they?

Based on the above, it is not difficult to understand that, ideally, metal (iron) doors with glass and a ventilation grill should be installed in boiler rooms. More precisely, "cold" rolled steel is used. It is bent in profile. Important: in any case, a fireproof lock is used. Also, when using metal, a "core" of a non-combustible material is usually used.

The perimeter is equipped with a tape expanding when heated. Equipping with a smoke seal is widely practiced. It is unacceptable to use a plastic element with glazing - this type of canvas will not withstand the load arising from potential explosions. An exception is made only with a glazing thickness of 4 to 6 mm, no more. Typical dimensions of structures can be:

- 0.8x1.8 m;

- 0.8x, 1.9 m;

- 0.8x2.03 m;

- 0.86x2.05 m;

- 0.96x2.05 m.

Attention should be paid to the width of the canvas. Usually it is, as already mentioned, at least 0.8 m.But ideally, it is better to make an opening 1 or even 1.2 m wide. The classic solution is to use powder-coated door surfaces. This is a budget option that suits almost all consumers.

If there is a need for a more perfect decoration, in an exclusive design, then even forged lattices can be used. Such gratings are installed on glass, MDF and many other materials. As a result, you can create a truly unique image of the door and achieve a chic visual effect.

And the use of perforated door leaves allows for a truly effective outflow and overflow of air.

How to choose?

When selecting doors to the boiler room, the main attention should be paid to equipping with a ventilation grill (or rather, how powerful this grill is and whether it allows air to pass through well). It is equally important to familiarize yourself with the characteristics of the canvas. The certificates must state what the strength of the structure is and what operating temperatures it is designed for.

Another relevant nuance is the total time of resistance to fire. It makes no sense to purchase doors for a gas boiler that are unable to withstand an open fire for at least 45 minutes. Ideally, you should focus on a level of at least 60 minutes.

As for the doors to the boiler room, the glazing area there (together with the window) can range from 0 to 80%. Dealing with ventilation, it is necessary to choose the right air exchange grille - not just according to the area norm (from 0.8 sq. M.), But also taking into account the required intensity of air flows. To determine them, a careful calculation will be required. Only professionals can perform it properly.

A significant air flow through the supply valve cannot be ensured. A passage 10-15 cm wide is quite enough. As fire doors in a cottage, it is categorically impossible to put structures with a wooden canvas. Even the best impregnations only provide fire resistance up to 40 minutes, which is completely unacceptable for safety reasons.

The handle option for opening the door is selected at your discretion.

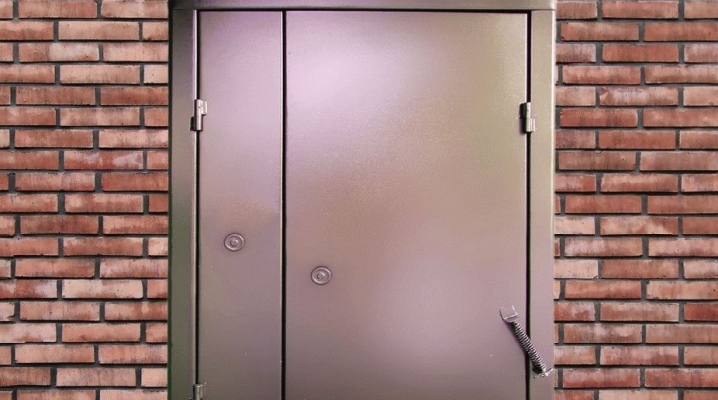

The boiler room can be supplied with double doors from the StroyStalInvest company. A model measuring 2.5x1.6 m is quite suitable even for a large room; even high cylinders can be safely brought in through such an opening. The structure consists of 2 bendable sheets with a thickness of 0.15 cm. Together with the narthex, the thickness of the box reaches 8.4 cm.This door provides ventilation and is powder coated on the front.

The modification of "DK-2" from the Lux enterprise also deserves attention. The standard size is 2x0.8 m, but it can be easily changed. The standard thickness of the metal (0.2 cm) is also corrected if necessary. 2 hinge protection elements are provided. The product is equipped with an upper safe and lower lever locks (at the customer's option).

You can also consider the model "DMPD-60". Its main parameters:

- production in solid and glazed versions;

- complete readiness for use in basic version;

- reinforcing ribs in the shape of the letter P;

- one piece bent fabric;

- nut with a height of 5.5 cm;

- lock with polypropylene handle;

- powder coating (weather resistant);

- filling the internal volume with a basalt slab;

- a box made of a complicated bent profile.

For the requirements for boiler rooms in a private house, see the video.

The comment was sent successfully.