Smokehouse for meat: simple design options

A smokehouse, if it is well designed and correctly applied, allows you to give various products a unique aroma, inimitable taste. And - significantly increase the shelf life of food products. Therefore, the choice of a suitable design option must be approached as carefully as possible and take into account all the nuances, sometimes the smallest ones.

Peculiarities

There are two main smoking modes: cold and hot. The processing mode in these modes differs significantly, and for each of them special devices must be used. The cold processing method uses smoke, the average temperature of which is 25 degrees. The processing time is considerable: it is at least 6 hours, and sometimes reaches several days.

The advantages of this solution are as follows:

- the longest possible storage of products;

- a processed piece of meat can retain its taste for many months;

- the ability to smoke sausage.

But it should be borne in mind that it will not work to store cold-smoked products in the refrigerator. To build a suitable smokehouse, you will have to use an area of 250 x 300 cm.

Hot smoking requires heating the smoke to 100 degrees. This is a very quick operation (20 to 240 minutes), and therefore this method is suitable for home and field processing of products. The taste is slightly worse and the food should be consumed within 48 hours of processing.

The simplest scheme

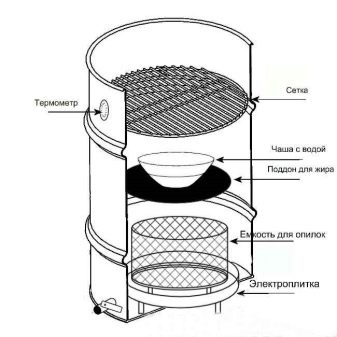

Making a smoking oven with your own hands is quite simple: you need to make a tight closed container with a hermetically sealed lid, supplement it with a grate and hooks to hold food. A pallet must be provided where excess water and fat could drain. If you follow this schematic diagram, the design and creation of a smokehouse will not be difficult: chips or sawdust are poured into the bucket, a pallet is placed, and a grate is placed 0.1 m from the edge.

It is very easy to process a small amount of food in such a bucket. But if you need to smoke sausage, semi-finished products, it is advisable to use larger-scale products.

Full-fledged homemade apparatus

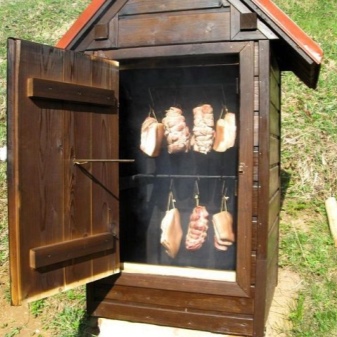

For a cold smoker, the soil must be prepared first. In the place where the heating chamber will be installed, bricks or wooden blocks (logs) are placed, which must be buried 0.2 m deep. Having strengthened the platform, they put the camera itself, which is easy to build from buckets or barrels. A fire pit should be 200-250 cm wide and approximately 0.5 m deep. A chimney must be laid from the fire to the smoking chamber (a special tunnel must be dug). Laying slate helps to reduce heat loss.

It should be noted that the preparation of smoked meats must be regulated by varying the strength of combustion. For this, an iron sheet or piece of slate is placed directly above the fire, the location of which can be changed. To increase the retention of smoke in the smokehouse, covering it with a moistened rough cloth helps; to avoid the fall of such a shell, special rods in the upper part of the chamber help. To fill the smoking apparatus with food, you need to make a special door in the side of the structure.

It is recommended to make chambers in the form of a circle or a rectangle, and heat retention is improved by using a "sandwich" structure, the gap between the walls of which is filled with soil.

Other processing methods

The drawings of the hot smokehouse are somewhat different - it is more difficult to make such a system. The heating chamber is placed inside a cone-shaped smoke jacket. The seams of the apparatus must be strictly sealed, there is no need for a pallet. As a result, the meat becomes bitter in taste and is filled with harmful components. When dripping fat is burned, the combustion products saturate those products that have decided to smoke, therefore the outflow of fats is necessarily thought out.

Since the chips should smolder, and not burn in any way, it is required to heat the bottom of the smoking chamber. Smoke generators help to avoid softening of meat, bacon or fish by the resulting condensation. The best models of smoke generators have a hydraulic seal and a branch pipe.

Most amateur craftsmen prefer semi-hot smokers. Often they are even made from unnecessary refrigerator cases from which they are removed: a compressor device, tubes for pumping freons, a freezer, plastic parts, thermal protection. Air exchange is provided by the remaining tubes.

However, it will take too long to heat the smokehouse from the old refrigerator - it is much more practical and economical to use old washing machines for these purposes (especially for small and medium portions of smoked meats). They remove motors with activators and relays, and the hole where the shaft is located is made wider to facilitate the escape of smoke. The fat is discharged through the former drain.

If you need to raise the smokehouse above the surface, you can form a kind of podium from cement parts, the gaps between which are filled with a mixture of clay and sand. When using the simplest design based on a barrel, it is recommended to lay out its perimeter with a brick border of a low height. The upper part of the container and the holes drilled in it serve to secure metal rods and hooks from which you can hang food pieces. Ceramic tiles are often used for facing the ends.

Important: it is worthwhile to provide for the consolidation of large portions of meat or fish, since small smoked pieces dry out quickly, become tough and tasteless.

For information on how to make a smokehouse with your own hands, see the next video.

The comment was sent successfully.