Weight and volume of brickwork

The weight of the brickwork is an important indicator and is calculated at the design stage. The strength and appearance of the future foundation, as well as design solutions and architecture of the building, depend entirely on how heavy the load-bearing walls of the structure will be.

The need to determine the mass

It is necessary to know exactly the weight of one cubic meter of brickwork for many reasons. First of all, this, of course, is the calculation of the maximum permissible load on the foundation and floors. Brick is considered a rather heavy building material, therefore, in order to use it for the construction of capital walls, it is necessary to clearly correlate the permissible load and the specific gravity of the brick. Often a limitation for the use of bricks, especially silicate and hyper-pressed solid models, is the type of soil. So, it is not recommended to use brickwork on loose and moving soils. In such cases, alternative materials should be used: expanded clay concrete blocks, foam concrete, gas silicate material or cinder blocks.

Knowing the exact weight of one cube. m of brickwork, you can calculate not only the strength of the foundation, but also to determine the margin of safety for each section of the load-bearing wall. This is especially important for calculating the load on the lower and basement floors, as well as for choosing the grade of cement mortar and reinforcing elements of the structure. In addition, an accurate knowledge of the mass of brickwork allows you to calculate the required carrying capacity of a vehicle on which construction waste will be removed during dismantling of structures and dismantling of walls.

What affects weight?

The mass of the masonry is primarily influenced by the material for making the brick. The lightest are ceramic products, for the manufacture of which clay and plasticizers are used. Products are molded using a special press, and then sent to the kiln for firing. Slightly heavier are silicate and hyper-pressed products. For the manufacture of the former, lime and quartz sand are used, and the basis of the latter is cement. Clinker models are also quite heavy, made from high-melting clay grades, followed by firing at very high temperatures.

In addition to the material of manufacture, the type of brick execution has a huge impact on the weight of a square meter of masonry. On this basis, two large groups of products are distinguished: solid and hollow models. The first are monolithic products of regular shapes that do not contain shaped holes and internal cavities. Solid stones weigh on average 30% heavier than their hollow counterpart. However, such a material has a high thermal conductivity and is rarely used for the construction of load-bearing walls. This is due to the absence of an air gap in the brick body and its inability to prevent heat loss in the premises during the cold period.

Hollow models are distinguished by higher performance characteristics and lighter weight, which allows them to be most actively used in the construction of external walls. Another factor affecting the mass of brickwork is the porosity of the brick. The more internal cavities a product has, the higher its thermal insulation qualities and lower weight.To increase the porosity of ceramic models, sawdust or straw is added to the raw materials at the production stage, which burn out during the firing process and leave a large number of small air voids in their place. This allows for the same volume of material to significantly reduce its weight.

In addition, the weight of the mortar and metal reinforcement has a huge impact on the mass of the masonry. The first factor largely depends on the professionalism of the bricklayer, as well as on how thick he applies the mortar. The mass of reinforcing elements depends on the number and type of metal structures required to give the walls of the building increased strength and seismic resistance. It often happens that the total weight of the grout and reinforcing mesh is almost equal to the net weight of the brick.

Calculation rules

Before proceeding with the calculation of the mass of brickwork, you should familiarize yourself with some terms. There is a specific and volumetric weight of a brick. Specific gravity is determined by the ratio of weight to volume and is calculated according to the following formula: Y = P * G, where P is the density of the brick, and G denotes a constant value of 9.81. The specific gravity of a brick is measured in newtons per cubic meter and is denoted as N / m3. To translate the numbers obtained into the SI system, they must be multiplied by a factor of 0.102. Thus, with an average weight of 4 kg for full-bodied models, the specific weight of the masonry will vary from 1400 to 1990 kg / m3.

Another important parameter is the volumetric weight, which, in contrast to the specific weight, takes into account the presence of cavities and voids. This value is used to determine the mass of not each brick separately, but immediately a whole cubic meter of products. It is the volumetric weight of products that serves as an indicative value and is taken into account when calculating the mass of brickwork directly during construction.

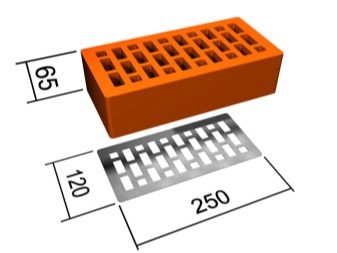

Knowing the weight of one brick and the number of copies in one cubic meter of masonry, you can easily calculate how much the entire masonry weighs. To do this, it is enough to multiply both numbers and add the mass of cement mortar to the obtained value. So, in one cubic meter, 513 solid single silicate products of a standard size 250x120x65 mm fit, and the weight of one brick is 3.7 kg. Therefore, one cube of masonry will weigh 1898 kg without taking into account the weight of the mortar. One and a half silicates already weigh about 4.8 kg per piece, and their number per cubic meter of masonry reaches 379 pieces. Accordingly, a masonry of such a volume will weigh 1819 kg, also without taking into account the mass of cement.

The calculation of the mass of red brick masonry is carried out according to the same scheme, but with the difference that single full-bodied models weigh 3.5 kg, while the weight of hollow ones reaches 2.3-2.5 kg. This means that one cube of ceramic masonry will weigh from 1690 to 1847 kg excluding cement mortar. However, it should be noted that these calculations are only suitable for products with a standard size of 250x120x65 mm. So, narrow hollow models with a width of not 120, but 85 mm will weigh only 1.7 kg, while the weight of dimensional copies of 250x120x88 mm will reach 3.1 kg.

As for the consumption of cement, on average 0.3 m3 of mortar is spent per cubic meter of masonry, the mass of which reaches 500 kg. Thus, 0.5 tons should be added to the obtained value of the net weight of a cubic meter of brick. As a result, it turns out that the brickwork has an average mass of 2-2.5 tons.

However, these calculations are only approximate. To determine the weight of a structure with an accuracy of a kilogram, a number of factors that are purely individual for each case should be taken into account. These include the conditions for storing bricks and the coefficient of its water absorption, the grade of cement, the consistency of the mortar and the total weight of the reinforcing elements.

For information on how to calculate the brickwork, see the next video.

The comment was sent successfully.