How to make a machine and make a cinder block?

The range of building materials today cannot but please with its diversity, however, many people prefer to make such products with their own hands. So, it is quite possible to make cinder blocks in great demand by yourself using a special home-made machine. Today we will analyze in detail how to do this correctly.

Material features

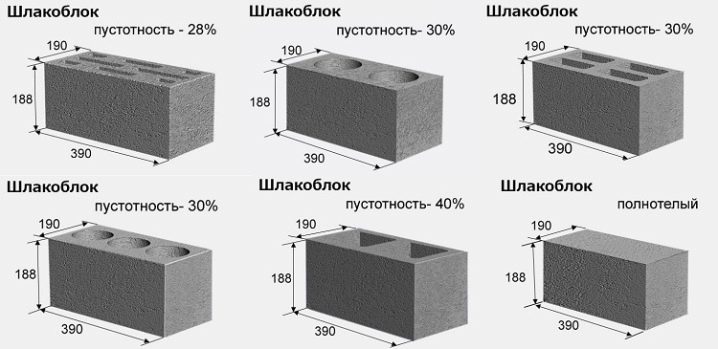

Cinder block is a building material that has established itself as one of the most durable and unpretentious. It has considerable dimensions, especially if you put an ordinary brick next to it. Slag blocks can be made not only in a factory setting. Some masters undertake such work at home. If you strictly adhere to the technology, you get high-quality and strong blocks, from which you can build a house or any kind of outbuilding.

If a decision was made to independently manufacture such products, then a number of its features should be taken into account.

- Cinder block is a fireproof material. It does not ignite itself, nor does it intensify an already active flame.

- Really high quality blocks produce durable and sustainable homes / outbuildings. Neither harsh climatic conditions, nor hurricanes, nor constant gusty winds will harm such buildings.

- Repair of cinder block buildings does not require extra effort and free time - all work can be carried out in a short time.

- Cinder blocks are also distinguished by their large dimensions, thanks to which buildings from them are erected very quickly, which pleases many builders.

- This material is durable. Buildings built from it can last more than 100 years without losing their previous characteristics.

- Another feature of the cinder block is its soundproofing component. So, in dwellings made of this material, there is no annoying street noise.

- The production of cinder blocks is carried out using various raw materials, so it is possible to choose the optimal product for any conditions.

- The cinder block is also distinguished by the fact that it is not attacked by all sorts of parasites or rodents. In addition, it does not rot, so it does not have to be coated with antiseptic solutions and other similar compounds designed to protect the base.

- Despite their decent dimensions, such blocks are lightweight. This feature is noted by many masters. Thanks to their lightness, these materials can be easily moved from one place to another without having to call a crane. However, it should be borne in mind that some varieties of such products are still quite heavy.

- Cinder block is not afraid of low temperatures.

- These blocks are distinguished by their high heat capacity, due to which cozy and warm dwellings are obtained from them.

- Temperature jumps do not harm the cinder block.

- Cinder block buildings are usually finished with decorative materials to give a more aesthetic appearance. However, it is very important to remember that the cinder block cannot be covered with ordinary plaster (any "wet" work with this material should not be carried out). You can also use a special decorative block, which is often used instead of expensive cladding.

- When working with a cinder block, it is important to take into account one important feature - such a material is characterized by high water absorption, so it must be protected from contact with moisture and dampness. Otherwise, the blocks may collapse over time.

- Unfortunately, the geometry of the slag blocks is poor. That is why, laying out overlappings from such material, you will have to constantly adjust individual elements - cut them and saw them.

- Cinder blocks are relatively low cost.

According to experts, such materials are quite capricious in their work, so it is always very important to follow the relevant instructions. The same applies to the process of their manufacture.

The composition of the mixture

The production of slag blocks at home obliges the master to adhere to a specific composition, as well as certain proportions of all components. So, cement with a grade of at least M400 is usually an astringent ingredient in this material. As for the filling component, it can consist entirely of slag or be mixed. The last option is obtained by adding a small amount of gravel, sand (plain or expanded clay), chipped brick and fine expanded clay.

In the manufacture of cinder blocks, the following proportions must be observed:

- 8-9 parts of the filling component;

- 1.5-2 parts of an astringent ingredient.

If, in the process of work, cement with the M500 marking was used, then it is permissible to take it by 15% less than the M400 raw material. Most often, an element such as slag occupies at least 65% of the total filler volume.

For example, out of 9 parts, at least 6 falls on this component, and the rest of the volume falls on gravel and sand. In theory, when self-manufacturing, it is permissible to use concrete or brick battle, screening.

The standard cinder block proportions are:

- 2 pieces of sand;

- 2 parts of crushed stone;

- 7 parts of slag;

- 2 parts of Portland cement marked M400.

As for water, it is customary to add it in an approximate ratio of 0.5 part. The result is a semi-dry solution. To make sure of its high quality, you need to take a small handful and throw it on a hard surface. If the thrown lump crumbles, but under compression has regained its former shape, then the composition can be considered suitable for further use.

If it is planned to obtain a colored cinder block, then the recipe is supplemented with colored chalk or brick chips. To increase the strength characteristics of this material, special plasticizers are used. In some cases, they turn to the addition of gypsum, ash or sawdust.

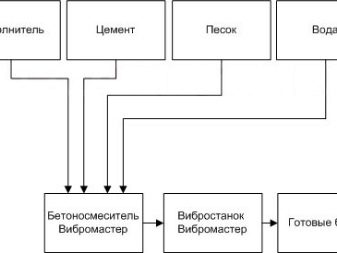

It is recommended to mix all of the listed components in a special mixer or concrete mixer, but such equipment usually has a high price. If we are talking about preparing a small amount of a mixture, then it is possible to knead it manually, despite the fact that such a process is considered quite laborious.

Forming methods

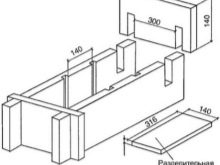

Factory molds for the preparation of cinder blocks are made of reinforced concrete or steel. Such parts can easily support the weight of the solution in a large volume. As for self-prepared forms, they are most often made from wood or steel sheets. Such elements to a greater extent play the role of a special formwork.

To save on raw materials and free time, molds are mostly assembled without a bottom. You can put a simple film under them. Thanks to this method, the entire block formation process can be significantly simplified. It must be remembered that the forms themselves must be made of perfectly smooth wood pieces. In this case, the working surface will be a concrete base, a table with a flat and smooth tabletop, or a sheet of iron, which also has no defects.

Many craftsmen use glass bottles to create voids. You should not take a container made of plastic, since it can seriously wrinkle. The bottles are filled with water.Otherwise, they will float on the surface of the prepared composition.

Let's take a closer look at how to make a mold for slag blocks:

- you need to choose sanded boards with a length of 14 cm (the width should be a multiple of this parameter);

- further, using a hacksaw, you need to separate the segments, which will then play the role of transverse partitions;

- then you need to connect the segments with longitudinal elements to get a rectangular frame;

- then you need to cut a sheet of steel or any other material with a smooth surface into separate plates measuring 14x30 cm;

- in the inner part of the resulting structure, cuts are made, which will act as grooves, the width of which is equal to the dimensions of the dividing strips;

- then the sections responsible for the separation are fixed in the cuts, creating a mold for the manufacture of 3 or more slag blocks.

In order for the resulting container for hardening the solution to serve as long as possible, at the final stage, both metal and wood structures are advised to be coated with oil-based paint. A similar form is suitable for the preparation of cinder blocks, the dimensions of which are 14x14x30 cm.

If it is necessary to make elements with other dimensional parameters, then the initial values are changed to other sizes.

How to make a vibrating machine?

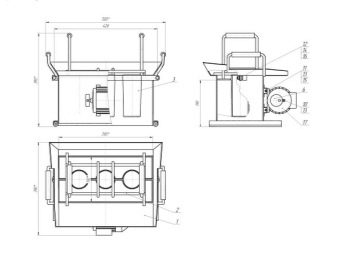

It will be possible to make slag blocks at home using a special vibrating table, which can also be made by hand. The main component of such a device is the vibrating mold itself for the solution. Such a machine is a steel box in which parts with voids (or without them) are fixed. The matrix itself is already a machine tool. It is allowed to be applied by performing some steps manually.

To make a vibrating machine yourself, you need to buy:

- welding machine;

- grinder;

- in a vice;

- tool for carrying out plumbing work.

As for the materials, you will need:

- steel sheet 3 mm - 1 sq. m;

- pipes with a diameter of 75-90 mm - 1 m;

- 3 mm steel strip - 0.3 m;

- electric motor with a power of 500-750 W;

- nuts and bolts.

Consider the procedure for carrying out work on the manufacture of a homemade vibrating machine.

- Measure a standard slag block or record the specific parameters you need.

- Cut out the side parts of the machine from the sheet of metal. Based on the number of cinder blocks, provide the required number of partitions. As a result, a box is formed with 2 (or more) identical compartments.

- The bottom wall with a thickness of at least 30 mm must have voids. Based on this parameter, we determine the height of the cylinder that bounds the voids.

- We cut 6 separate pieces of pipe with a length corresponding to the height of the cylinder.

- In order for the cylinders to acquire a conical structure, it is permissible to cut them lengthwise to the middle part, squeeze them with a vice, and then join them by welding. In this case, the diameter of the elements will decrease by about 2-3 mm.

- The cylinders must be welded on both sides.

- Further, these parts should be connected to each other in the form of one row, following along the long side of the future cinder block. They should repeat the location of the voids on the factory element. At the edges it is necessary to attach a 30 mm plate with holes for fastening to the lugs.

- A cut should be made in the center of each die compartment and an eye should be welded. This is necessary to ensure that the temporary holders are installed.

- On the outer transverse wall, 4 bolts are welded for the mounting holes of the motor.

- Next, the apron and blades are welded along the edges in the places where the loading is carried out.

- After that, you can proceed to the preparation of all elements for painting.

- You can make a press that repeats the shape of the mechanism using a plate with holes, the diameter of which is 3-5 mm larger than the cylinders themselves. The plate should fit smoothly to a depth of 50-70 mm into the box where the limiting parts are.

- The handles must be welded to the press.

- Now it is permissible to paint the equipment and fix the vibration motor.

Production technology

There are two ways in which slag blocks are made.

- The easy way. In this case, special containers are used, being in which the prepared solution acquires the required strength. The blocks dry naturally until the cement is completely solidified.

- The hard way. With this manufacturing method, vibration devices are used. In many cases, they refer to elements such as a vibrating table or complement the shape with a motor with a vibration function.

Let's get acquainted with the technology of manufacturing slag blocks using simple forms.

- All prepared ingredients in the required proportions are placed in a concrete mixer and then thoroughly mixed.

- The finished solution is poured into molds. As for the ramming, it is carried out with a hammer - containers are tapped with them so that all the air leaves the material.

- If the blocks are planned to be made with voids, then bottles with water are placed in each separate part (usually 2 bottles are enough).

The main difficulty with this manufacturing method is the ramming of the blocks. If air bubbles remain inside the solution, this will have an adverse effect on the quality of the final product.

As for a more complex method of producing cinder blocks, the following work is carried out here:

- starting the production of materials in this way should be by stirring the mixture in a concrete mixer;

- the resulting solution is sent to the mold, and then leveled with a trowel;

- then the vibrator is started, and the solution itself is kept in shape for 20-60 seconds;

- then the equipment must be turned off, the installation is lifted, and then the finished unit is removed.

In the manufacture of slag blocks using this technology, special attention should be paid to leveling the mortar in the corner sections. They must be filled in. Otherwise, the geometry of the finished product can be seriously affected.

Drying

Drying is another important step in the manufacture of slag blocks. The production process itself usually takes about 2-4 days. Sufficient strength characteristics that allow the transition to the use of blocks are usually achieved after 28 days. It is this amount of time that is needed to obtain a high-quality building material suitable for carrying out certain works. Also, cinder blocks can dry naturally. As a rule, this process takes place with a simple method of making materials (in conventional forms).

For drying cinder blocks, special chambers are often used, which prevent cracking during their hardening. To prevent the blocks from becoming covered with cracks, they must be wetted from time to time. This process is especially relevant if the production process is carried out in hot weather.

It is worth noting that the cinder block hardening process can be significantly accelerated. This effect can be achieved by adding special substances to the solution - plasticizers. With such additives, the material will not only dry faster, but will also be stronger. Cinder blocks with plasticizers can be removed from the site and stored after 6-8 hours.

Tips & Tricks

- To make the front side of the cinder blocks more accurate and intact, these materials for drying should be placed on a flat rubber base.

- Never place blocks on top of each other while they are drying. Otherwise, the materials may turn out to be deformed, and their geometry will cause many problems during construction work.

- In all cases, you should first make drawings of the forms and the slag blocks themselves. Thus, many difficulties associated with construction processes will be avoided.

- When preparing the mortar, be sure to adhere to the required proportions.The slightest errors can lead to the fact that the blocks are too fragile and unsuitable for construction.

- Before pouring the prepared solution, the molds should be wiped. This will prevent cinder blocks from sticking to the bottom and walls. For cleaning, diesel fuel, waste oil or other similar compounds are most often used.

- Please note that the rate of hardening of the solution directly depends on its density. The thicker the composition, the sooner the blocks will solidify.

- It is recommended to cover the slag blocks with polyethylene for the drying period. The film will be able to protect the material from cracking in hot weather, and also keep the cinder blocks from getting wet if it suddenly rains.

- If in the manufacture of slag parts you want to save a little, then you can combine lime and cement in a 3 to 1 ratio. Do not worry about the quality of cinder blocks - they will not become less reliable from such a composition.

For information on how to make a cinder block machine for 4 blocks, see the next video.

The comment was sent successfully.