Fireclay brick: features, varieties and subtleties of use

When building a stove or fireplace in a house, the need to use materials that are resistant to fire comes to the fore. That is why most of the buyers make their choice in favor of fireclay bricks. This building material can withstand extremely high temperatures and direct long-term exposure to flame. It is noteworthy that chamotte does not deform and does not crumble even with prolonged heating.

What it is?

Fireclay brick is characterized by a very simple composition, based on crushed dried fireclay powder, the concentration of which is 65-70%. This substance is made from simple white clay, which is purified and fired for a long time, due to which it exhibits pronounced refractory characteristics. Additionally, coke, as well as graphite fillers and coarse quartz grains are introduced into the raw materials. The initial components are thoroughly mixed, then molded and sent for firing and pressure testing.

It is the firing features that determine the basic operational parameters of the material. The duration of the baking of the material is of great importance. So, if the raw material is overexposed in a thermal oven, then a glassy film appears on its surface. It is quite strong and gives the material a special resistance to mechanical damage, but fire resistance at the same time decreases.

If, on the contrary, the firing is insufficient, such a material will perfectly absorb and retain moisture inside itself, and therefore its strength will be very doubtful. The best bricks for stoves and fireplaces can be obtained only if you adhere to the "golden mean".

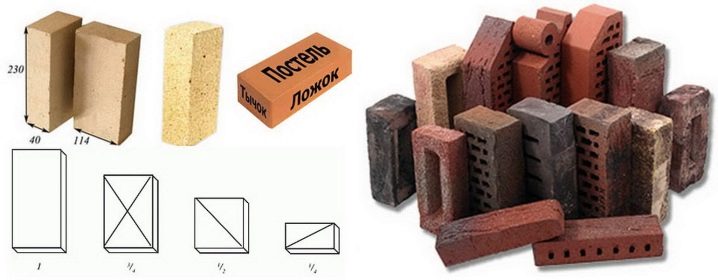

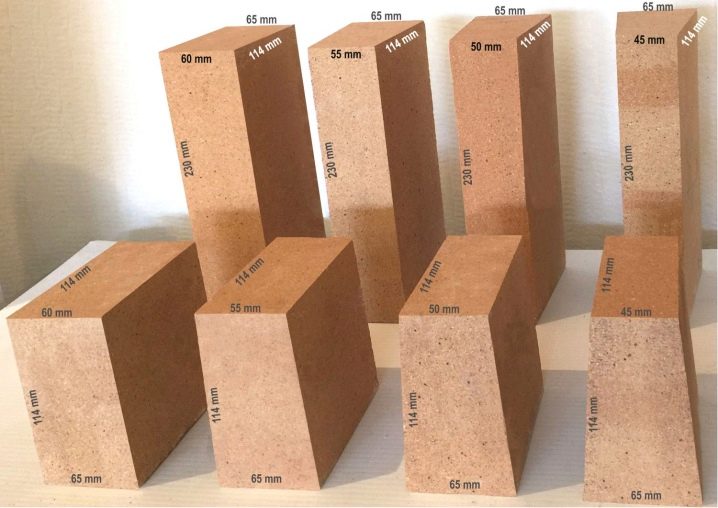

The production of fireclay bricks is regulated by current standards, while its dimensions and weight can often vary significantly: from 2.5 to 6 kg, and the parameters are 230x111x65 mm, as well as 300x150x65 and 250x123x65 mm. In addition, the products differ in terms of density and porosity of the structure.

Specifications

Fireclay building material made according to the existing technology, there are a number of operational features:

- the color of the product should be light yellow, rather straw with an admixture of brown blotches;

- the structure of the brick is only granular;

- when hitting a brick, a ringing like metal is heard;

- the material is characterized by an increased degree of strength, therefore, with a slight damage, the structure of the chamotte remains unchanged.

Professional builders and finishers highlight both the advantages and disadvantages of such a brick.

The advantages include the following parameters.

- Strict geometry of parts is extremely important when using materials with a wedge-shaped bevel.

- Heat resistance. The internal structure of the brick is not affected in any way by prolonged exposure to elevated temperatures; such a material can withstand heating up to 1500 degrees or more. It should be noted that, in principle, heating of more than 1000 degrees from all types of bricks can only withstand fireclay.

- Low thermal conductivity. This characteristic, as well as the low density of certain types of material, make such a brick the best option for installing chimneys and various pipes.

- Fortress. Fireclay materials have the ability to withstand even fairly strong mechanical stress.

- Chemical resistance.Products made of chamotte perfectly tolerate the effects of various acid-base solutions and resist many other chemical reagents.

However, nothing ideal has yet been invented, and fireclay bricks are no exception. There are also negative aspects associated with its use.

- If the firing technology is not followed correctly, then the dimensions of the products and their level of quality change significantly.

- Fireclay materials are not at all low cost, so they cannot be considered affordable for most of our compatriots.

- Not all solutions are suitable for masonry. Usually a special compound called "mortar" is used, and it must be applied very carefully, so that the layer is very thin.

- The increased strength significantly limits the ability to cut the material. It can only be cut with a special diamond blade for stone.

It should be noted that the existing negative aspects do not in any way reduce the popularity of the material and do not limit its use in the arrangement of fireplaces and home stoves.

Application area

Fireclay bricks are widely used in industry, and are also often used for the construction of various types of fuel chambers and process boilers. It is in them that coal is burned.

The material is also common in everyday life, here it found its application for the construction of fireplace inserts, kitchen hearths and wood-burning stoves. For chimneys, experts also recommend taking precisely fire-resistant chamotte blocks, they can withstand not only hot air, but also adverse types of atmospheric influences.

There are a lot of rumors and myths around the features of the material. It is believed that when heated, it begins to emit harmful components and even radiation. Experts completely refute all these theories. Moreover, if the last statement is still in principle possible in theory (if the brick is made of clay mined in an area exposed to radiation contamination), then the first is impossible to believe. Most likely, the reason for the appearance of such rumors is the following: some types of fire-resistant materials, indeed, when exposed to hot air, begin to emit toxic substances. However, this does not apply to the fireclay block, since it was originally created as a material for domestic use.

Views

Chamotte bricks differ for a number of reasons:

- by molding;

- by the type of finished product;

- by porosity.

Depending on the variant of the formation of raw materials, there are several types of fireclay bricks:

- semi-dry molded;

- molten;

- thermoplastic extruded;

- cast;

- hot pressed.

By type of brick, there are shaped, figured, wedge, as well as arched and trapezoidal types. The most popular is considered to be chamotte in the shape of a rectangle, but when installing arched structures, it is better to use wedge material. Depending on the level of porosity, there are:

- high-density brick - with a grain size not higher than 3%;

- high-density - in this case, the graininess is differentiated from 3 to 10%;

- dense - with a porosity parameter from 10 to 16%;

- refractory compacted - with a porosity parameter of about 16-20%;

- medium-dense - differs in grain size at the level of 20-30%;

- highly porous - in this case, the grain size corresponds to 30-45%;

- lightweight - with increased grain size of 45-85%;

- ultra-lightweight - in this case, the graininess exceeds 85%.

Separately, it is necessary to dwell on such a variant of fireclay bricks as quite popular lightweight products. These bricks are usually used instead of insulation. They consist of special oily clay, as well as peat, shavings or sawdust and some other organic components. During heat treatment, they completely burn out, leaving pores of various sizes in their place.As a result of this technology, a porous material with high energy efficiency is obtained.

Lightweight bricks are made entirely of organic substances, therefore, they are considered environmentally friendly, they do not emit harmful and toxic substances, and therefore are suitable for use in residential premises. By the way, the special structure does not affect the thermal resistance of the material in any way: lightweight bricks can withstand even extremely high impacts up to 1800 ° C.

As for the shape, such bricks are wedge-shaped or rectangular. In order for the material to fully retain all its original operational characteristics in full, it must have a strict geometry with even corners and edges.

Lightweight bricks are generally used to form a layer of thermal insulation when equipping electric furnaces, as well as evaporators and heaters. Quite often, it is purchased for lining heat exchange boilers and steam pipelines. At the same time, such protection can significantly reduce heat losses (by 25-75%) and thereby reduce the dimensions of heating devices. Experts note that if you take fireclay materials for lining furnaces, then the heating and cooling period will decrease by 5 times, while all heating costs will be reduced by 10-15% in continuously functioning furnaces and by 45% in those that work from time to time ...

Stamps

All fireclay products in Russia are subject to mandatory marking, which is applied to one side of the brick. Usually manufacturers make it up from several letters and numbers, while the total number of characters varies from 5 to 47. The characters in the marking indicate the chemical and physical characteristics of the material. You can usually see the following symbols.

- SHA / SHB / SHAK - under this designation are bricks of general purpose, which have extremely high strength parameters and are able to withstand heating up to 1700 ° C. Such brands are very popular with developers because they have an optimal price / quality ratio.

- ШВ / ШУС - marking for industrial fireclay. It is characterized by a high heat capacity, therefore it is optimal for arranging gas passages of heat generators, as well as for lining the enclosures of convective shafts.

- ShK - such materials are used in the construction of industrial technological equipment for the production of coke.

- SHL is a brick that is characterized by a high degree of porosity. It is most often used for the lining of industrial furnaces and can maintain its operational properties under prolonged exposure to high temperatures (up to 1300 ° C).

- ШЦУ - is a fire-resistant end blocks, which are widely used for the manufacture of rotating parts of industrial furnaces.

- PB - represents the usual chamotte, which is widely used in everyday life.

- PV - includes products that have found their application in the installation of chimneys and the interior of home fireplaces.

The numbers indicate the dimensions of the brick in strict accordance with the current regulations and standards. For example, under the marking ШБ-8 there is a brick with dimensions of 250х124х65 mm, and ША-5 is a product with parameters 230х114х65 mm.

How to choose?

Fireclay brick is quite expensive, so you need to take it seriously. If you buy low-quality material, you risk simply losing all your money. If you find yourself in a hardware store with a good reputation, this does not at all guarantee that you will be offered an ideal product without external defects, therefore, when choosing, pay attention to all the important details.

- The basic indicator of product quality is its color, it must certainly be straw yellow. If you have lighter, almost white blocks in front of you, most likely you see in front of you a brick that has not been fired in the oven, which absorbs moisture well and is subject to destruction from the inside.And heat accumulates in it much worse, which means that functionality will be a big question.

- The brick should have a fairly even surface and a perfect shape. Many believe that these requirements are dictated by the aesthetic component of the project, but this is far from the case. The fact is that when arranging a fireplace or stove, the inner surface must be smooth, any relief obtained as a result of the preservation of the remains of the solution or the swelling of the brick leads to the creation of barriers to the flow of heated gas. If the defect is not eliminated, then an uneven distribution of heat begins, as a result, the level of traction will be insufficient, and the heat transfer will drop dramatically.

- The kiln masonry is distinguished by a very strong joining of fireclay bricks, a small number of seams and a tight fit. If the material used has cracks, chips and other defects, then it is impossible to ensure reliable adhesion. In this regard, when buying bricks, be sure to choose them from the same batch. Otherwise, you risk getting a completely heterogeneous material, which can have a most deplorable effect on the operational characteristics of your future thermal element.

How to put it right?

The technology of building stoves and fireplaces from fireclay bricks at home consists of 2 stages:

- preparatory work;

- directly masonry.

At the stage of preparation for work, all future corners and walls are marked, as well as the production of the necessary adhesive mortar and preliminary dry masonry. For permanent laying of bricks, a special composition is used, it can be bought ready-made in the store, or you can cook it yourself. You will need refractory powdery clay, high-quality chamotte sand, and industrial water.

First you need to grind the clay, then sift all the sand and add water to the resulting clay-sand mixture with constant stirring. The finished composition is left for two to three days, stirring from time to time. Clay and sand are taken in a ratio of 1: 2, some builders recommend adding salt or 3% liquid glass to the composition at the rate of 100 g per 10 liters of water.

Fire-resistant bricks are first cut and then fastened so that each next row completely overlaps the seams between all blocks of the previous row. This technology determines the strength of the entire structure, and also contributes to the normal redistribution of the load.

When laying with your own hands, pay special attention to the jointing. If it is done incorrectly, that is, the seam is too deep or not completely sealed, drops of rain and snow begin to get inside (this applies to street structures), and when cold weather sets in, the masonry cracks. A fireplace that is cracked at the seams cannot perform all its functions in full, and its heat capacity is significantly reduced.

For information on how to properly lay fireclay bricks with your own hands, see the next video.

The comment was sent successfully.