One-and-a-half brick: what is it, types, dimensions and how is it different from a single brick?

One-and-a-half brick is rapidly gaining popularity today in the construction of residential and industrial facilities and cladding of building facades. It allows you to significantly save time and effort on carrying out the necessary work.

What is it and what is it for?

In simple terms, a one-and-a-half brick is a regular brick block, but slightly increased in height. The need for such a material appeared in the era of total development, when the construction industry was required to build houses quickly and at minimal cost. It was then that the manufacturers slightly increased the initial parameters of the brick in length, height and width and proposed a technology for the manufacture of a modern and much more efficient material.

At first glance, it may seem that a one-and-a-half brick is not much more than usual and the savings, if any, are not particularly noticeable. This is a common misconception. On the one hand, one single brick does not differ much from a single one, however, on the general scale of construction, the savings become very tangible. Just imagine: three lorries are the same thickness as four standard blocks, which significantly reduces installation time and the amount of grout required.

There is also a certain aesthetic moment: the use of one-and-a-half blocks reduces the number of seams. In this case, only the large blocks themselves are striking, which have a very interesting texture. By the way, the modern construction industry offers both smooth and rough bricks, options with a wood-like texture are popular, and the choice of shades is quite wide.

One-and-a-half brick has found wide application in the construction of multi-storey buildings, cottages, as well as in the construction of outbuildings and fences. Often the material is used for facing facades, but it is not recommended to take it for the installation of foundations and plinths; here it is better to give preference to other options.

Classification

Due to the dimensions, which are 1.35-1.4 times larger than the standard, the use of one-and-a-half brick makes it possible to achieve significant savings. Today, manufacturers offer several options for such a building block: ordinary, front, torn, hollow, corpulent, and many others.

By properties and functional purpose

Depending on the functional purpose and technical and physical features, several types of one-and-a-half bricks are distinguished.

Ceramic is a block made of purified clay without impurities (such as marl and sulfate), with the addition of components that give the material the required parameters. Such a brick is classified as a natural, environmentally friendly material, it does not accumulate toxic substances and does not emit radiation.

It is made by two main methods:

- Plastic. Ordinary clay with a high moisture content (up to 25-30%) enters the kiln from a belt press, dried and fired at elevated temperatures (about 1000 ° C).It is extremely important that the firing time is kept as accurately as possible, since both the unburned and the burnt block are characterized by a deterioration in their operational characteristics, which leads to a decrease in the quality level of the housing being built, and the general appearance of such materials leaves much to be desired. With insufficient firing, the block has a rather light red tint, is characterized by low water resistance and cannot withstand prolonged frosts, and if firing, on the contrary, was excessive, then the surface of such bricks is covered with numerous cracks and takes on a curved shape. Ideally, if firing has been carried out in accordance with current production standards, the surface of the ceramic block should become slightly dull, and a specific sonorous sound should be heard under mechanical action.

- Semi-pressing method. In this case, the brick is molded from clay with low moisture parameters (no more than 10%) under the influence of strong pressing. Products obtained in this way are not recommended for the construction of premises that will be operated in unheated conditions with a high level of moisture in the air.

The advantages of ceramic bricks are obvious:

- increased noise insulation;

- environmental friendliness of products - the material is made of clay, which is completely safe for life and health both at the stage of construction and at the stage of use;

- versatility - it can be used both for the installation of industrial facilities and for the construction of residential buildings, the material is used both for external cladding and for the installation of internal partitions;

- resistance to fluctuations in high and low temperatures and extreme frosts;

- duration of operation;

- strength and strength;

- excellent steam and heat insulation;

- water resistance.

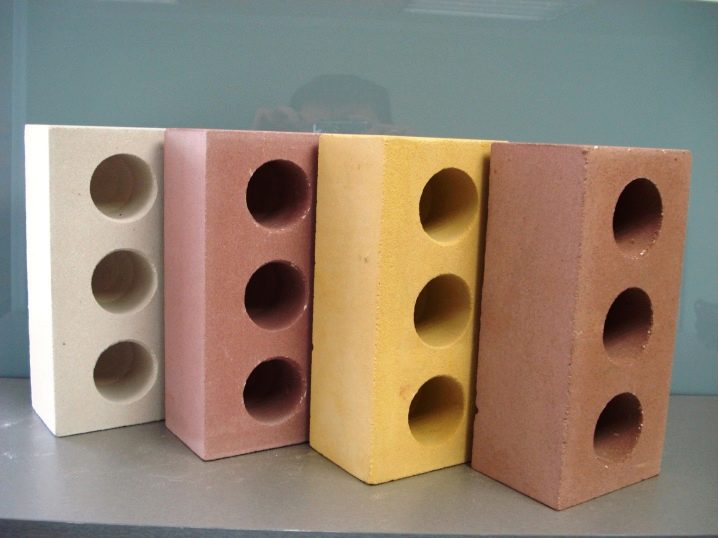

It is noteworthy that the modern market offers a wide selection of ceramic bricks in various colors, this is achieved by mixing several types of clay. The tint palette of finished products is very rich: red, dark brown, sandy, peach and even beige tones. Thanks to such a huge selection, ceramic one-and-a-half blocks are very often used in various restoration work and the construction of new buildings.

Silicate brick-and-a-half belongs to the category of artificial building materials that are made not from natural, but from synthetic components. The mixture that is used in production is called silicate, it includes lime and quartz sand in a ratio of 1 to 9. In order for the raw material to take the desired shape, various plastic additives are introduced to it, most often chemically resistant pigments, thanks to which it is possible to obtain material of different colors and textures.

Silicate brick has many advantages, among them:

- low thermal conductivity - due to this, in the cold season, warm air is retained inside the dwelling;

- environmental Safety;

- high noise absorption;

- long period of service;

- strength and strength;

- resistance to low temperatures and other adverse atmospheric factors;

- affordable price - silicate bricks are about 30% cheaper than red ceramic bricks;

- clear geometry;

- wide range of tones and textures.

Among the disadvantages of silicate bricks, it should be noted low resistance to moisture, so it should not be bought for equipping plinths, building sewer wells and laying foundations, that is, all zero-cycle structures where there is an increased likelihood of flooding or regular contact with groundwater.

Important: in residential buildings, silicate blocks are often purchased for the installation of chimneys and stoves due to their low cost. This is a common mistake, such a material is characterized by a low heat resistance, therefore, under the influence of high temperatures, the masonry begins to collapse rather quickly.

Clinker brick - this material is very similar to ceramic, because, in the same way as it is made from a clay mixture, however, in this case only certain types of clay are suitable. The process itself consists in the fact that the prepared and shaped raw materials are fired at extremely high temperatures until they are completely baked. As a rule, heating is carried out at 1200 degrees. Thanks to this technology, the material acquires special strength characteristics and durability.

Hyper-pressed - a unique manufacturing technology is considered a characteristic feature of the composition. Such a stone is not formed in furnaces at high temperatures, but by pressing the clay mass under high pressure, which usually varies from 23 to 35 MPa. The raw material is limestone, to which cement and water are added.

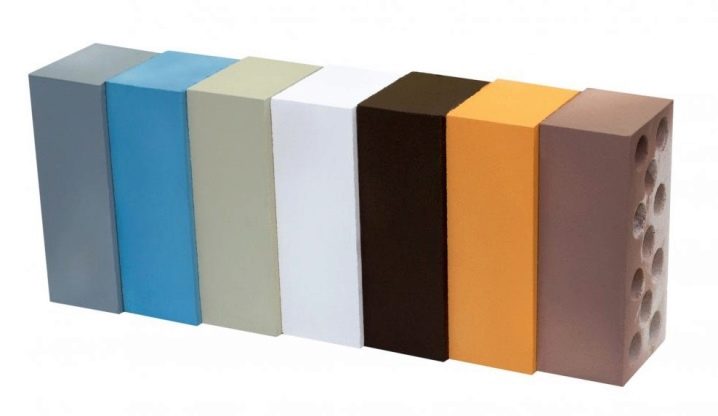

By design

Modern manufacturers produce both standard white unpainted blocks and colored ones. Colored, as a rule, are intended for exterior decoration of buildings and the creation of unusual decorative elements. Such a brick can be not only red, but also have the most unusual color schemes: green, ivory, blue, rubble, brown, beige, chocolate, coffee, etc.

The material can differ greatly in texture: in hardware stores, both rough and, on the contrary, smooth blocks are presented, which, in turn, are matte or glossy. These parameters are determined by the features of the brick processing technology. Facing materials can have a glossy texture, this is achieved by applying a special glaze to the fired clay, which is a fairly low-melting glass-based composition. Thanks to this layer, the brick receives increased resistance to moisture and temperature fluctuations.

A wide color palette is possible due to the imposition of a special color composition on a slightly dried raw material, after which the prepared products are subjected to final firing. Such a coating is made from clay by adding natural or chemical dyes to it. If the processing temperature is selected correctly, then such a color layer becomes opaque, but at the same time extremely beautiful.

By the way, colored bricks are not nearly as strong as simple glossy ones. To be more precise, only the coating is not strong enough, which gives them a characteristic color, as a result, the facing over time loses its decorative and aesthetics. All this resulted in low demand for colored blocks.

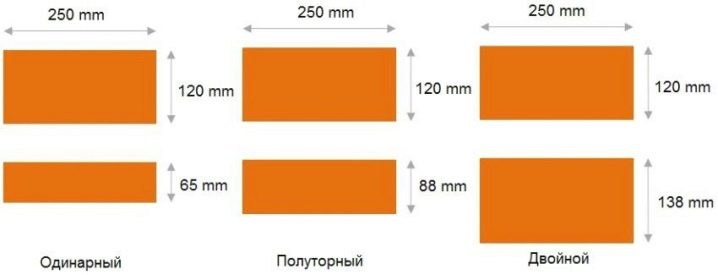

The size of one and a half bricks - how many centimeters is it?

The dimensions of a brick-and-a-half are:

- length - 25 cm;

- width - 12 cm;

- height - 8.8 cm.

Blocks are subdivided into empty and full-bodied. In solid bodies, the maximum number of voids does not exceed 15%; in hollow bodies, the permissible level of through and blind holes is 30%. In silicate blocks, voids are usually located closer to the center, while in ceramic blocks they are evenly distributed throughout the entire internal cavity and differ in an uneven shape.

The presence of such chambers allows to reduce the consumption of raw materials for the manufacture of building blocks, which means that the time spent on construction and the final cost per square meter of the building object are reduced. The low weight creates a reduced load on the structural supports. So, the mass of one-and-a-half ceramic bricks with voids is approximately 3-3.3 kg, and the mass of full-bodied bricks is 4-4.3 kg. The difference for facing products is also obvious - 5 kg for corpulent ones versus 3.9 kg for bricks with voids.

What is the difference between a single and a "lorry"?

The difference between the traditional single block and a lorry one and a half lies in their economic efficiency. Calculations show that for 1 m3 of masonry, the material consumption is exactly 394 blocks - when using single products and 302 blocks - when using one-and-a-half bricks. Due to this, it is possible to significantly reduce construction costs.

So, when forming the supporting structure when laying with a single brick, 3 rows of standard units and 1 row of facing ones are made. With a one-and-a-half brick, the consumption is less - only 3 rows of hollow and 1 row of finishing. Thus, the consumption of the solution and the material itself is significantly saved.

One and a half brick is considered an ideal option for profitable development, which is carried out in a short time. The height of a lorry exceeds the corresponding size of a single one only by 23 mm, but even this difference allows all laying work to be carried out 30% faster.

How to make brickwork from one-and-a-half silicate bricks, you will learn from the video below.

The comment was sent successfully.