Firing bricks

Brick firing is the final stage of its production.

Firing bricks at home is quite possible, despite the fact that it seems difficult. And many people have already proved that not only large brick factories, but also ordinary people can do it. The process of creating bricks with your own hands is advisable only for a planned large construction site or for the sale of products.

In principle, building, chessboard solid bricks can be produced at home.

Stages

To create a brick, you will need to go through several stages:

- preparation of material,

- shaping bricks,

- drying

- burning.

The last stage is the most time consuming, costly and responsible. At this stage, it is very important to adhere to the production technology so that a marriage does not come out.

An oven is required for firing. Its construction will not take long. Ovens are rectangular and round. The shape of the oven does not affect the quality of the product, it is chosen exclusively according to taste.

The firing of bricks at the factory is shown in the following photo.

Another factory furnace looks like this:

When choosing a place to install the stove, you need to remember about fire safety. Install the stove away from combustible buildings and materials. It is also advisable to have a water source or other extinguishing means on hand.

Construction stages:

- First you need to create the foundation for the future oven. The depth is about 50cm, and other dimensions depend on the shape of the oven. But the foundation should protrude 5-10 cm beyond the boundaries of the oven.

- Walls are built on the foundation, the wall should be 50cm thick. After the construction of 2/3 of the height of the walls, the thickness decreases to 25 cm and a narrowing begins to form a chimney. There must be an opening in the wall for loading blanks.

- After the structure is ready, a layer of fine gravel 10 cm thick is poured onto the bottom of the furnace. As a matter of fact, everything is ready.

- Now you need to properly load the blanks into the finished furnace. They are positioned so that there is some space between the workpieces for heat to enter there. The workpieces are placed at the rate of approximately 220-240 pieces per cubic meter. Above, you can place 300 pieces for the same volume.

- Charcoal or wood is best suited for the firebox. Better, of course, coal. Sometimes burners are used to create the desired temperature.

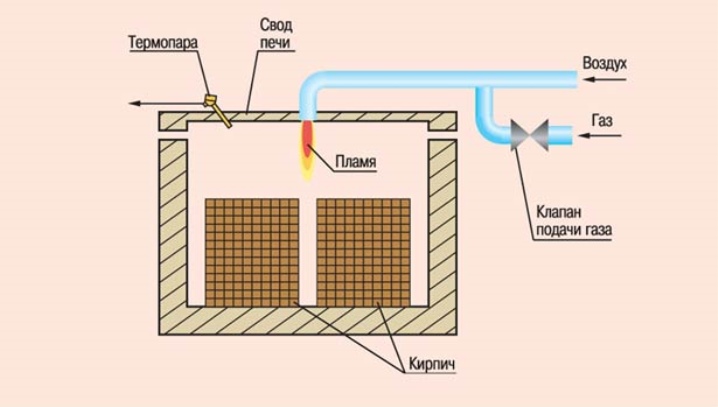

A diagram of a gas kiln for firing bricks is shown in the figure.

To begin with, the workpieces must be dried for 2-3 days at a temperature of 160-200 ° C. Then the temperature is increased to 900-1000 ° C. And so to maintain 3-4 days.

Cooling should be done slowly. To do this, the opening in the furnace must be bricked up and covered with clay so that air does not get there.

After cooling down, it is necessary to check the quality of the finished brick. To do this, it is lightly tapped with a hammer. If the brick is of good quality, there should be no damage, and the sound should be clear. Those bricks that did not work out can be sent for re-firing or used to build interior walls.

The comment was sent successfully.