Facing brick: types, design and tips for choosing

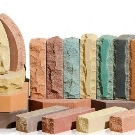

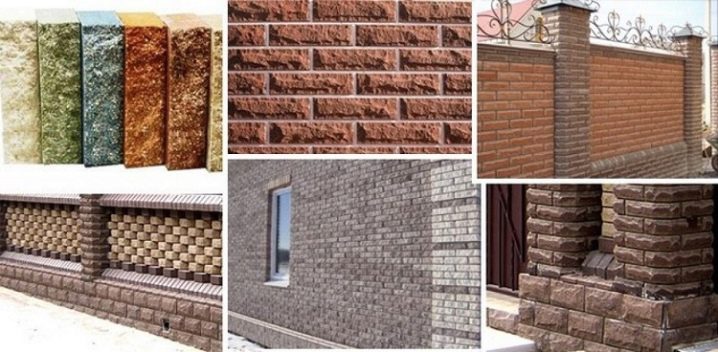

Facing bricks have excellent decorative properties and are widely used for decoration of building facades and interior spaces. The material is available in a wide range, in a wide variety of colors and textures, which greatly simplifies the choice of the desired option and makes it even more popular.

Peculiarities

Facing brick is a versatile finishing material that allows you to hide flaws in the brickwork of load-bearing walls, additionally insulate the facade and give the building a spectacular and noble look. The house, faced with decorative bricks, becomes the center of attention and looks very presentable. The main difference between the face stone and ordinary silicate or ceramic products is the surface texture, color scale and composition.

Limestone, cement and red clay act as raw materials for the production of facing models, and additives, plasticizers, pigments and dyes are used as additional components. The presence of certain components, as well as their percentage, is determined by the type of face stone and the technology of its manufacture.

High consumer demand for facing material is due to a number of its indisputable advantages. Among them, one can single out the high decorative properties of bricks, which is explained by a wide color palette and a wide variety of shapes, textures and designs. In addition, the lined surface significantly reduces the heat loss of the premises and does not allow extraneous noise from the street to penetrate inside.

The advantages include the high thermal stability of most models, as well as their ability to withstand sudden temperature changes. The brick-lined facade tolerates high humidity conditions and is not afraid of frequent and prolonged precipitation. Due to the high resistance of the face stone to aggressive environmental conditions, the material can be used in any climatic zone, including areas with a sharply continental climate and northern territories.

However, along with numerous advantages, the material has a number of disadvantages. The disadvantages include the risk of excessive load on the foundation, the high cost of some types and the need to use expensive adhesive mixtures for facing. The scope of use of facing bricks is quite extensive. In addition to cladding the basement and the facade, the material is actively used in the construction of fences and columns, as well as for finishing small architectural forms: arches, gazebos and garden and park fences.

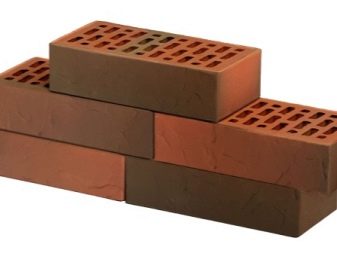

All facing stone is available in 2 versions: solid and hollow. Hollow models weigh 30% less than their solid counterparts and are distinguished by higher thermal insulation characteristics and a low price. The use of hollow bricks increases the heat-saving properties of the cladding by 15% in comparison with the use of solid products. Therefore, when using full-bodied models as a finish, the necessary measures should be taken to additional insulation of the facade.

Views

The classification of facing bricks is made according to the technology of its manufacture.In total, four varieties are distinguished, each of which has only its inherent operational characteristics and decorative properties.

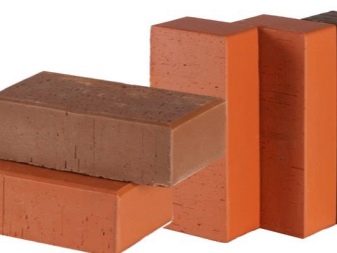

Ceramic brick

The raw material for the production of this material is red clay. The essence of the manufacturing method is reduced to the formation of clay blanks by means of a special press with their further drying and firing in special furnaces. In addition to clay, the composition of the material includes mineral additives and plasticizers, which serve to improve the working qualities of the finished brick. Coal dust, slag, ash and quartz sand are used as such additives. The main difference between the facing stone production technology is the careful processing of all components before mixing. The finished product should be free from foreign inclusions and visible defects.

The surface of ceramic facing products varies. In addition to a matte and glossy finish with a smooth texture, the kiln production method allows you to get relief models with an imitation of natural stone. The color palette of ceramic products is also varied. Mineral components such as chromium oxide, finely ground iron or manganese ore and all kinds of pigments are used as dyes.

The absence of toxic and poisonous components, as well as the natural origin of the main raw materials, make the ceramic stone completely safe and environmentally friendly and allow it to be used not only for external, but also for internal finishing work. In addition, ceramics does not absorb moisture and allows air to pass through well, ensuring the ability of the material to "breathe" and eliminating the risk of mold and mildew.

The advantages of ceramic cladding include absolute fire safety, high sound insulation qualities, resistance to temperature fluctuations, ease of installation and the availability of a huge range of ceramics on the market for every budget and taste. The disadvantages include a fairly high cost and the likelihood of purchasing low-quality products. The latter is caused by a violation of the technology of kneading and firing clay, as a result of which the stone becomes quite fragile and ugly.

To protect yourself from buying defective material, you need to use the services of trusted suppliers who purchase products from reliable manufacturers.

Clinker brick

Clinker brick is a kind of ceramic and is also made from clay. Its main difference from ordinary ceramic bricks is the quality of the raw materials and the firing temperature. The basis of clinker products is refractory clay, and heat treatment takes place at very high temperatures, reaching 1200 degrees. The brick made in this way is characterized by high density and minimal water absorption. This allows the use of clinker material not only for the design of the basement and facade cladding, but also for paving sidewalks, paths and bridges.

Clinker brick copes well with aggressive environmental influences and is able to withstand up to 100 freeze-thaw cycles, which makes it one of the most durable facing materials. The undoubted advantages of clinker products include low hygroscopicity, resistance to fading in the sun, excellent thermal insulation properties and high decorative capabilities. The disadvantages include a fairly large weight of products, which significantly increases the load on the foundation, and high thermal conductivity. In addition, the adhesive properties of the clinker are not very high. This is due to the poor absorbency of the material, which makes the application of adhesives and putty compounds very difficult.

Hyper pressed stone

Hyper-pressed stone is produced by non-fired pressing. A mixture of granite screening, shell rock, cement and water is used as a raw material for its manufacture.By its structure and composition, the material is concrete of special strength, made in the form of a brick. Due to its increased strength and excellent resistance to weathering, hyper-pressed stone is an ideal option for exterior design and is in no way inferior to clinker products in terms of its performance properties.

Externally, hyper-pressed brick is very similar to natural stone and looks spectacular in masonry. During the manufacturing process, the concrete solution is easily mixed with a variety of dyes and is available on the market of finishing materials in a wide color palette.

However, along with the obvious advantages, concrete still has disadvantages. The disadvantages include the likelihood of cracking, which is caused by thermal expansion of the material, as well as an increasingly noticeable loss of color over time. In addition, the concrete stone has a sufficiently large weight, which causes additional stress on the foundation and supporting structures.

Low vapor permeability is also considered a disadvantage, requiring additional measures to ensure the ventilation of the facade.

Silicate brick

Sand lime brick was especially popular at the end of the last century. Old wooden buildings were lined with them, giving them an unrecognizable look and prolonging their life. The material was notable for wide consumer availability and low price. Today, silicate brick has given way to the palm of more modern facing materials and has become less and less used as a finishing material. This is due, first of all, not too expressive decorative qualities of the products and rather heavy weight.

The main raw materials for the production of silicate are slaked lime and quartz sand. The manufacturing technology of the material consists in forming blanks with their subsequent placement in special autoclaves, where the composition hardens under the influence of high temperature and pressure. The advantage of facing silicate bricks is a high frost resistance index, which allows the material to easily endure over 75 freeze-thaw cycles without losing its integrity and working qualities.

In addition, the brick is absolutely harmless to human health, which is due to the absence of toxic additives and synthetic dyes in its composition. There is also a high biological resistance of the material to mold and mildew. In addition, silicate is not interesting for rodents and insects, perfectly insulates the room and is compatible with any type of solution. The advantages also include low cost, ease of installation, clear geometric shapes and standard dimensions.

The disadvantages of silicate models include high water permeability, reaching 8%, increased thermal conductivity and too much weight. Full-bodied models weigh almost 30% more than ceramic ones and require a capital foundation and strong walls.

Dimensions (edit)

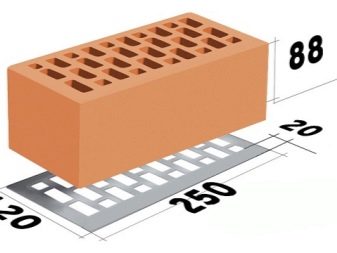

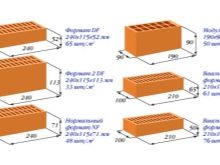

The dimensions of each type of facing brick are strictly stipulated by the norms of the state standard and are always spelled out in the accompanying documentation. This greatly facilitates the calculation and acquisition of the required amount of material. The norms of a single standard were determined in the first half of the last century, namely in 1927, and have remained unchanged since then. The standard applies to both ordinary construction and front models, and has the following meanings: the dimensions of a silicate and ceramic single stone are 250x120x65 mm, double - 250x120x138, thickened or one-and-a-half - 250x120x88 mm.

However, GOST also provides for non-standard options, the most popular of which are narrow 0.7NF marking products, the size of which is 250x85x65 mm. The one-and-a-half version of such specimens has dimensions of 250x85x88 mm.These products are used in the restoration of old buildings, allowing to significantly reduce the load on their foundations. The dimensions of clinker bricks are somewhat different from the size of silicate and ceramic, and in addition to the standard 250x120x65, they have options 250x90x65 and 250x60x65 mm. As you can see, only the height of the product changes, while the length and width remain the same. An exception is the elongated model with dimensions of 528x108x37 mm, which is more than twice as long as the base versions.

Non-fired hyper-pressed bricks are also available in four standard sizes: 250x120x65, 250x90x65, 250x60x65 and 250x120x88 mm. In addition to the Russian GOST, the European standard is widely represented on the market, in which there are 2 categories: NF and DF. The NF index denotes products of the traditional format measuring 240x115x71 mm, while DF includes thin models corresponding to the architectural classics with dimensions of 240x115x52 mm. In order to avoid problems with bandaging the seams when facing the facade, it is recommended to purchase products of only one of the standards.

Standardization of dimensions allows you to calculate the required amount of material for facing a certain areaand also calculate the weight of the cladding. So, to finish one square of the surface, 61 single (25x12x6.5 cm), 45 one-and-a-half (25x12x8.8 cm) and 30 double bricks with a size of 25x12x13.8 cm will be required.However, these calculations are given without taking into account the seams. Taking them into account, the required number of products will look like 51, 39 and 26 pieces, respectively.

The cladding weight is calculated individually, taking into account the type of material and its thickness. The weight of single models starts from 1.7 kg, while double full-bodied silicate products can reach 6 kg.

Color palette

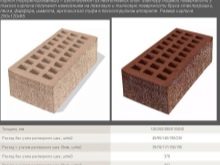

The modern market of facing materials presents a huge number of brick colors. Ceramic models are presented mainly in red and brown tones, but the variety of their shades is so huge that it will not be difficult to choose a material for every taste. But despite the great variety of color solutions, many consumers prefer natural, without the use of dyes and pigments, clay color.

However, when choosing products in natural colors, you need to be very careful. Bricks of different batches often differ from each other, which is very noticeable on the facade and spoils its appearance. The difference in color is due to the quality and ratio of the additives used when kneading the clays, as well as a violation of the firing technology.

Hyper-pressed bricks have perhaps the widest color palette. The material is painted in the desired colors by adding dyes and pigments. This technology makes it possible to achieve the same uniform color throughout the entire volume of the brick, and, subject to the necessary proportions of the coloring components, makes the products of different batches absolutely indistinguishable in color.

Peach and beige concrete products, as well as straw, ivory and light chocolate models are in particular demand. Black and white bricks also look good on the facade, and lovers of non-standard solutions will appreciate the burgundy, terracotta and green shades.

Sand-lime brick is painted according to the same principle as concrete. Pigment or dye is added using a special dispenser during kneading. However, it should be noted that colored brick is somewhat inferior in strength to unpainted silicate. This is due to the significant share of paint in the total volume of raw materials, and in order to avoid a decrease in the performance of the material, many manufacturers paint only one of its sides. The most popular colors of sand-lime bricks are white, yellow and pink.

Shapes and texture

The surface of the facing brick also affects the overall appearance of the facade.And if silicate models have a mostly flat surface, then ceramic and clinker products are presented in a wide variety of textures and reliefs. The figured pattern is applied at the stage of forming the blanks, after which they are sent to the oven. In total, there are five technologies for decorating bricks.

- The gunning technique consists in applying decorative chips to the raw clinker models. Then the blanks are sent for firing, and the mineral chips are sintered with the edges of the brick and form an interesting texture.

- The engobing technique consists in applying a liquid ceramic mass to the surface of bricks dried before firing. Then the product is sent to the oven and at the exit gets a thin ceramic coating resembling a glassy film.

Sometimes ceramic mixtures are applied not to the entire workpiece, but only to its individual areas, resulting in smooth color transitions that attract attention with their uniqueness.

- The glazing method consists in applying a special composition to the unburned surface of a brick, the basis of which is glass powder. Then the workpiece goes for firing and as a result, a thicker and stronger glassy film is formed on its surface than in the previous case.

Glazed models are used not only for facades. The material has found wide application in the cladding of stoves, columns and interior decoration.

- The technique of textured application consists in the formation of the desired pattern or pattern on wet blanks with their subsequent firing. This method is used when decorating the surface of a stone semi-antique and to create an imitation of various textures.

- Chipped or rusticated bricks are obtained as a result of mechanical surface treatment that imitates a chipped natural stone. The products look very natural and are visually indistinguishable from the prototype from some distance. Popular colors for chipped patterns are shades of gray and brown.

Along with traditional models of facing bricks, shaped, or, as it is also called, figured stone, is in great demand. The material comes in a wide variety of shapes and colors and is used for cladding complex architectural elements such as columns, wood-burning stoves, arches and gazebos. Figured products are able to combine dissimilar surfaces and are indispensable for facing fireplaces and doorways.

How to choose?

The main criterion for choosing a facing brick is the ability of the foundation to carry an additional weight load. Usually, taking into account the weight of load-bearing structures, roofs and cladding is calculated at the design stage, however, if an already finished structure is to be faced, then it is necessary to raise the documentation and see the operational characteristics and the permitted load on the foundation.

If the basis of the house is reinforced concrete blocks, then you can purchase a brick based on personal preferences. But when facing old houses with strip foundations, it is better to opt for hollow ceramic single models.

The next criterion for choosing a material is its cost. So, the price of one lightweight ceramic stone is 12-20 rubles, while for a one-and-a-half hollow model you will have to pay from 20 to 28 rubles.

The cost of clinker products is slightly higher. A product with a smooth surface measuring 250x85x65 mm will cost at least 29 rubles, and a model of the same size, but with corrugated embossing, will cost 35 rubles. Hyper-pressed concrete stones cost about the same. Smooth models can be purchased for 23-25 rubles, while the price of textured copies varies from 25 to 30 rubles per brick.

If the funds allocated for the cladding of the house are not very much, then you can stop at colored silicate models. Their cost with a smooth design is only 15 rubles.Textured sand-lime bricks will cost a little more. Their cost lies in the range of 24-26 rubles. The most expensive are the products of foreign manufacturers, for which the price of one brick can go up to 130 rubles.

Manufacturers

To date, many enterprises are engaged in the production of facing bricks in Russia, however, the products of only a few of them have the greatest number of positive reviews.

- "Belebeyevsky brick factory" has been producing facing material for 23 years. The company has its own clay pit and specializes in the production of ceramic hollow models. The plant produces 60 million bricks per year and is the leader on the domestic market.

- "Golitsyn Ceramics Factory" produces a wide range of facing bricks. Along with mass production, the company has launched the production of exclusive premium two-tone models, as well as semi-antique relief items.

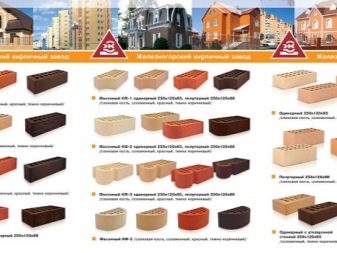

- "Zheleznogorsk brick factory" also well known in Russia and neighboring countries. The company has existed since 1994, and since its inception has managed to win the recognition of consumers. The production capacity of the plant is 40 million pieces per year, and the assortment is represented by several dozen models with imitation of velvet, stone and wood grain pattern. In addition, the company produces a huge amount of shaped solid bricks, as well as hollow convex and shaped bricks.

- "Kirovsky brick factory" produces up to 100 million pieces of silicate facing bricks of different shades. The company has established the production of hollow and solid products with a relief surface and the effect of chipped bricks.

- "Markinsky brick factory" also has its own quarry and is engaged in the production of environmentally friendly facing bricks. The unique grades of clay make it possible to manufacture products without the use of pigments and dyes, while obtaining models with an even and deep color. The enterprise uses high-tech foreign equipment and an electronic control system for each batch.

The manufactured products have both a smooth and a relief surface made in the form of a reef, reed or rock texture. The plant's production capacity is 65 million units per year.

Beautiful application examples

The modern market of facing materials offers a huge range of facing bricks. A wide variety of colors and textures greatly facilitates the choice and allows you to implement the most daring design decisions.

- Clinker bricks on the facade look elegant and noble.

- Inexpensive, but aesthetic sand-lime brick finish.

- The wide color palette of hyper-pressed products is mesmerizing.

- The ceramic stone in the facade cladding looks stylish and modern.

- Facing bricks with a glazed effect are very harmonious in the exterior decoration of public buildings.

For information on how to properly lay facing bricks, see the next video.

The comment was sent successfully.