Characteristics and application of brick grade M-150

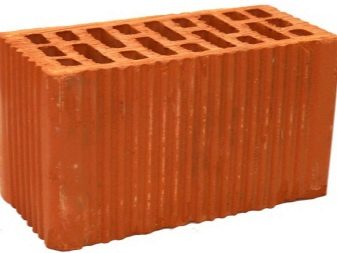

Ceramic brick M150 is widely used in low-rise construction, however, few people understand what is the main difference between this brand and many others. In our article we will tell you about the features of this material and the directions of its use.

What means?

Brick of the brand with the M-150 index can withstand a load of pressure up to 150 kg / cm2 (which is what the number in its designation means), therefore it can be used for a variety of types of construction work: for the construction of shopping centers, residential buildings and storage facilities.

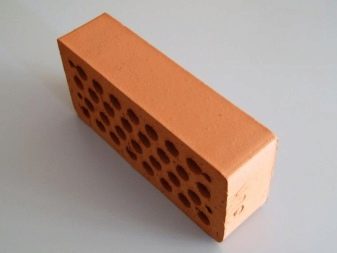

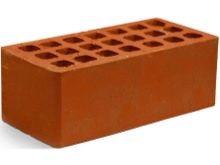

The material is offered in two main versions - hollow and solid, it retains heat well, has increased strength and has exceptional resistance to low temperatures.

A solid block of the M150 type is often used for arranging foundations, basements and plinths, although not too heavy buildings. This is a fairly strong building material that can withstand the weight of slabs and massive floors well.

In everyday life, such a building material is taken to decorate fireplaces and stoves of various modifications. Block m150 is ideal for the construction of a barbecue, in a word, it is suitable for absolutely any objects where solid fuel is not required, in this case it is better to give preference to refractory or fireclay bricks.

Hollow brick block M150 is optimal for installation of partitions in houses and cladding of external walls-facades, and thanks to the voids, it is lightweight, but at the same time retains exceptional density and good thermal insulation properties.

Due to its performance characteristics, the material can withstand strong external pressure. As a rule, such blocks are produced in a single size, but they can be one and a half, as well as double, which makes it possible to achieve significant savings during construction.

Brick of the M150 brand can be general construction, facing or special. It is much stronger than the products of the M75, M100 and M125 series.

It is noteworthy that the laying of such a brick is easy to do with your own hands, which significantly reduces the total cost of building buildings.

You can buy brick m150 absolutely anywhere in the sale of building and finishing materials, since this is a fairly common building material.

Advantages and disadvantages

The M150 block has excellent physical and technical parameters and an extremely aesthetic design, but the list of advantages does not end there. Masonry made of this material does not require any additional types of finishing work, therefore it often looks no worse than masonry made of expensive facing material, therefore it is often used for outdoor finishing work.

It is very important that such a brick has the ability to withstand adverse external influences. It can withstand temperature fluctuations, extreme frosts, prolonged direct exposure to sunlight, as well as the influence of precipitation and "proximity" to groundwater.

This brick is made from natural raw materials, therefore it has a high degree of environmental safety, it does not contain and does not emit harmful and toxic substances, including radiation.

By the way, the M150 product owes its great popularity to one significant advantage that distinguishes it from all other types of building products - its weight varies from 2.5 to 3.5 kg. Thanks to this small mass, the brick can be easily moved across different floors for all types of construction work.

Of the most important properties of bricks, it is necessary to highlight its high thermal insulation properties, therefore, in winter, heat is retained inside the building, and in summer, hot air does not penetrate from the outside, providing coolness and a favorable microclimate in the house.

M150 blocks are characterized by good sound absorption, therefore, its use is optimal in those situations where maximum sound insulation is to be ensured.

Among the disadvantages of bricks, one can name the likelihood of efflorescence on the surface, as well as a slightly higher cost in comparison with silicate bricks.

In addition, there are some nuances of using the mortar, since the brick will not be able to provide the required reliability and strength of the structure if a mortar of inadequate quality is used during laying. So, when bricks are used for the construction of outdoor facilities, it is better to use a cement compound. But for the house, limestone is more suitable. For cladding, special dry mixes are used, which can be purchased at any hardware store.

Views

All bricks of the M150 brand are produced in two main versions: working brick and facing brick. The difference is that the first belongs to the corpulent, and the second contains voids, such a subdivision is due to the structure of the material and its physical and technical characteristics. Solid blocks do not have any voids, but at the same time they have a slightly rough appearance, they are most often used for basement and basement rooms, as well as load-bearing walls and ceilings, which are subject to heavy loads.

Hollow bricks are lighter in weight, these blocks are characterized by increased resistance to low temperatures due to the presence of free space filled with air, walls of residential buildings and utility structures are everywhere erected from such bricks.

Facing block M150 has an ideal appearance, therefore it is widely used for facing facades, as well as columns and all kinds of decorative fences.

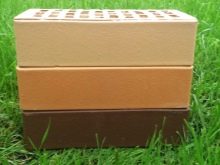

Nowadays, the industry produces M150 products in a variety of sizes and shapes, the most common are single, and even one and a half and double.

In addition, the product is offered in several shades, thanks to which it is used in a fairly large construction segment. Models with straw, as well as red, brown, brown shades are in the greatest demand. Recently, the production of products of more noble shades has been mastered - exquisite ivory, noble terracotta, aristocratic frost and chocolate.

The parameters of the M150 units supplied to the market directly depend on their modification. The most purchased one is considered to be a single brick with parameters 250x120x65 mm, used for the construction of main walls and supporting installations.

Difference from other brands

A distinctive feature of brick products is the brand of the product, which is determined as a result of several tests for strength in compression and bending, as well as for frost resistance. The strength parameter is conventionally denoted by the letter M, as well as by numbers - decryptions, which show what kind of load per 1 cm2 it can withstand, respectively, the larger the brand, the stronger the brick.

There are 8 stamps installed.

This is M with indicators from 75 to 300.

The most popular are the brands of blocks M-75, as well as M-100, M-125, M-150 and M-200.

The popularity of the M75 is due to its exceptional physical and technical features and external design. The material is very economical, which largely reduces the cost of the entire construction.

- M150 is distinguished by its strength, therefore it is more often used for the construction of partitions, load-bearing walls, fences and basements.

- M100 belongs to quite popular varieties of red brick, it is optimal for the installation of load-bearing and external walls, but you should not take it for cladding.

- M125 is also suitable for masonry walls, and it is also used for the installation of columns, interior pillars and various low buildings.

Products M125 and M150 are the most purchased in the construction of low-rise residential buildings, they are almost identical in their operational characteristics, but the only difference is that the M125 brick can withstand a load of 125 kg per square centimeter, and the M150 - 150 kg.

Marking bricks with the designation SUR, for example, SUR-150/35, means that in front of you is a silicate block made with the addition of plasticizers and artificial additives that improve the technical parameters of raw materials.

Manufacturing methods

Ceramic brick M150 is produced in two main ways: with the help of plastic molding and pressing, which, in turn, differs into dry and semi-dry.

The first method is more common and cost effective. In this case, clay is used, in the structure of which 30% of sand is included - such a structure prevents the likelihood of shrinkage of the dried finished product. The prepared raw materials are processed with steam and thoroughly mixed into a homogeneous mass, after which a raw bar is formed, usually it is 15% more than the finished product, since excess moisture is removed during the drying process. Technological firing is carried out in a kiln at a temperature of 1000 degrees Celsius.

When using the pressing method, the brick turns out to be smoother, but its frost resistance significantly lags behind that obtained by firing. The raw material in this case is clay with a moisture content of 8 to 12%, during processing it is completely crushed to a powdery state and pressed under high pressure. At the final stage, kiln firing is carried out.

Application

When planning construction work, the question often arises of which type of M150 bricks to choose. Everything is simple here: the solution depends entirely on the functional purpose of the future structure. For example, an ordinary hollow block is ideal for interior partitions and walls, it is small in size, therefore it allows you to save free space in the room, moreover, it has good sound insulation, and therefore, the inhabitants of the rooms will be reliably protected from external noise.

Tinted facing brick can be the best option for decorating the facade of a residential building. Fences can also be made of these bricks - they look simply luxurious, and thanks to a wide color palette, they can highlight the most original design ideas.

Double brick M150 is very durable, in addition, it differs in a reduced indicator of thermal conductivity, in this regard, the need for it often arises when installing warm walls, it is especially popular in low-rise housing construction. And also, the product is often used to form internal walls in rooms with a spacious area - this is due to its small width and good sound absorption.

You can watch the video below about the types of bricks and how to test it.

The comment was sent successfully.