Red bricks: description and varieties

Red brick is rightfully recognized as the most popular and well-known building material. Buildings made of it can be found on every street. A variety of buildings are made from such elements, from outbuildings to multi-storey buildings. Today we will take a closer look at this popular building materials and find out what types of it exist.

Advantages and disadvantages

Red brick, like many other building materials, has both positive and negative sides. You should definitely familiarize yourself with them if you plan to purchase such a product.

First, let's look at what these products are good for.

- Red brick boasts a fairly long service life without losing its attractive appearance.

- This building material is presented in the widest range. A wide variety of shapes and sizes can be easily found at the respective retail outlets. From them it will turn out to form structures of a very different structure.

- This building material is rightfully recognized as one of the simplest and most unpretentious in laying, so both experienced craftsmen and beginners can work with it.

- Buildings made from these raw materials are well soundproofed.

- High-quality red brick is not afraid of high dampness and moisture content, so you can safely build rooms like a bath from it.

- Red brick dries quickly if it gets wet.

- Thanks to this material, the most comfortable microclimate is created in the dwelling, which is a pleasure to be in.

- A number of defects that may appear on the surface of such building materials can be eliminated independently.

- Correctly made red brick is not afraid of either low or high temperature values.

- The facing brick is distinguished by an aesthetic way, therefore it is often used for the purpose of facing.

- These building materials are environmentally friendly and do not harm either human health or the environment.

Unfortunately, red brick is not without its drawbacks. Let's consider them.

- The walls erected from this building material are bad in that the efflorescence formed is immediately noticeable on them. As a rule, such flaws appear due to the use of a low-quality solution or the material itself.

- Porous bricks cannot boast of high reliability, since in the cold period they are especially strongly exposed to the destructive influence of water. In such conditions, these products begin to deteriorate. Liquid trapped inside the brick at low temperatures can easily rupture it.

- Different batches of bricks may have slight differences in shade, which can spoil the overall picture when facing.

- In modern retail outlets, there are too often lots of red bricks that are of poor quality. As a rule, they are presented as good products, but in reality they leave much to be desired. In many cases, at first glance, it is simply unrealistic to identify a second-rate brick.

- When choosing the best options, there is no way to check absolutely all of their qualities without contacting specialists and special laboratories.

Characteristics and composition

Red brick is a common building material that many users turn to. Buildings and houses of various configurations are built from it. This building material has certain characteristics that should be considered when choosing it.

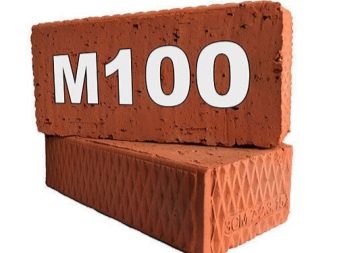

- Strength characteristics. Red brick is a fairly durable building material. This parameter is designated by the letter "M" and a number. You should pay attention to these designations when selecting high-quality and suitable products. There are bricks "M" 25-100. The higher the digital marking, the more impressive load the material can withstand per 1 sq. cm.

- Resistance to frost. Resistance to low temperatures is measured by the number of cycles. Each cycle consists of 2 main procedures - first, the brick is immersed in water for 8 hours, and then it is moved to the freezer for a similar time period. The level of frost resistance is determined at the moment when the building material changes some of its characteristics.

- Thermal conductivity. This characteristic is no less important than the same frost resistance. The coefficient of thermal conductivity indicates the amount of heat that can pass through a wall with a thickness of 1 meter under conditions of a temperature difference of 1 degree on both sides. This indicator is measured in watts. The more significant it is, the weaker the heat-conducting properties of the building material are.

There are 5 distinct categories of effective red brick. Each of them is distinguished by the ability to contain heat in the interior of the existing room. The minimum thermal conductivity is characterized by a full-bodied type of brick.

The main characteristics of this building material directly depend on the components present in its composition. It is possible to obtain a high quality product using good clay. So, the face type of brick is obtained from fine-grained clay. The best material is considered to be made from a clay composition without additional additives. In most cases, bricks are made from clay that is not suitable for preparing other pottery.

It should also be noted that in the production of red bricks, ingredients are often used, the content of which contains:

- kaolinite;

- illite;

- montmorillonite;

- quartz.

The primary properties of clay intended for the production of bricks include:

- high plasticity - the raw material should not be crumbly, if kneaded, and should also keep its shape (a little less often you can find absolutely non-plastic clay);

- binding ability - clay remains sufficiently plastic after adding auxiliary components;

- shrinkage - in this case, a change in size is meant during drying and firing;

- sintering property - here we mean the ability to harden when heated;

- fire resistance - during heating, the clay should not melt.

In many cases, in the manufacture of high-quality red bricks, not only one clay is used, but also various additives. They allow you to end up with a more reliable and attractive building material. These additives include:

- slag, ash and sand;

- coal and peat powder, sawdust;

- iron ore;

- sandstone;

- metal oxide.

How are they made?

The technology for making high-quality red bricks is quite simple and straightforward. In this case, it is extremely important to select the right raw materials and process them competently. Processing during such work is carried out in several stages. The required shape, appearance and structure of a popular building material is formed by the following steps.

- The first step is to grind the clay. After that, it is thoroughly mixed for a long time until the consistency becomes homogeneous.

- After that, additional components are introduced and the products are given the required shape.

- Then the bricks are exposed to dry so that the moisture leaves them. It should evaporate slowly from all sides (inside too).If mistakes were made at this stage, then the resulting brick will simply crack and collapse.

- Next, the resulting material is fired at a temperature of 800 degrees. The higher the melting point, the more firmly the individual components of the product will bond to each other. In this case, the masonry material will not undergo destruction or deformation.

Experts say that competent firing of red bricks can be determined by sound. It should be quite resonant and clear on impact. This indicator will indicate the good quality of the product.

If the brick has been melted for too long or under conditions of too high a temperature, then the inside will turn out to be black. Such (incorrectly fired) building material cannot be purchased for the manufacture of such important load-bearing walls.

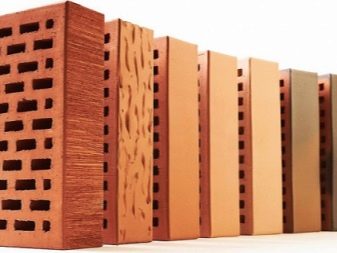

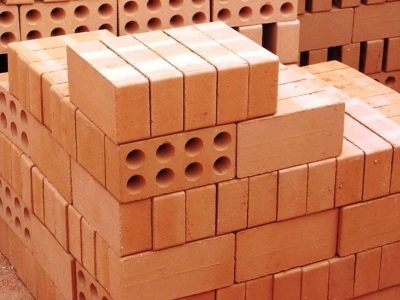

Views

Currently, there are several varieties of red brick. They differ in a number of characteristics.

- Ceramic. This type of red brick is recognized as standard and is most common. Ceramic specimens are made from baked clay or a combination of several of its varieties (usually no more than 3).

- Silicate. Such a brick is made in a special autoclave. In this case, sand and lime are used. The color of the finished material depends on the additives used.

- Private. It is a simple red-colored material used in the construction of wall structures, cesspools and other similar foundations.

Subsequently, it is decorated with various building mixtures, for example, plaster.

- Facial. This category includes fireclay and porcelain bricks, the top layer of which is covered with special chips. Such options are used for the purpose of cladding and decorative work. Such varieties are of high cost.

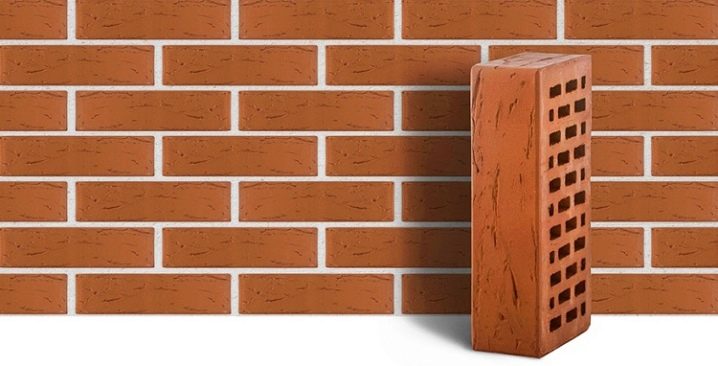

- Hollow. This type of red brick is porous and consists of a large number of holes of different sizes. It has good thermal properties.

- Corpulent. This is a brick that has no pores. Such materials usually have low thermal properties, but are denser.

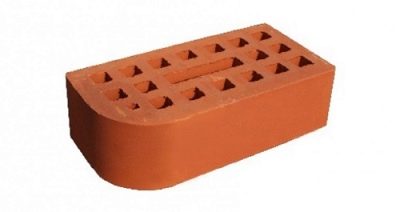

- Convex. Such varieties of red bricks are available in both one and a half and single. They have a non-standard shape and are more expensive than classic clay specimens.

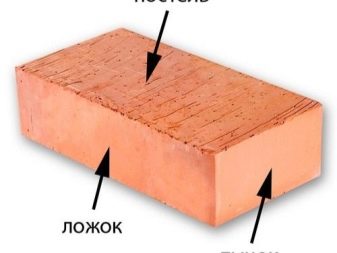

Stamps

When choosing a suitable lot of red brick, you need to pay special attention to its marking. So, the parameter of the height of these materials is indicated as follows:

- 1 NF (single options) - 6.5 cm;

- 1.4 NF (one and a half) - 8.8 cm;

- 2.1 NF (double) - 14 cm.

It is extremely rare on the Russian market to find bricks marked with 0.7 NF - these are options belonging to the "euro" category. Their height parameter is standard and is 6.5 cm, but the width is modest - 8.5 cm.

Another red brick is equipped with a mark in the form of the letter "M" and numbers from 50 to 300. These indicators indicate the greatest pressure (as mentioned earlier - with a difference of 1 degree on both sides). So, products with the M50 marking can only be used in the manufacture of fences or partitions.

As for any types of walls, it is recommended to use brick of the M75 or M100 brand. If you need to build a spectacular arched structure, then you need to refer to materials with a brand not lower than M125. For the preparation of plinths and foundations, it is worth using brick M175 and M150, as well as using other, more durable materials.

Applications

The scope of application of high-quality red brick is very wide. This demanded building material is used in the manufacture of the following bases:

- walls;

- fences;

- arched structures;

- partitions;

- sidewalks;

- enclosing and supporting structures;

- decorative finishes / cladding;

- fireplaces;

- chimneys;

- in the manufacture of ovens;

- foundations and plinths are made of bricks.

We should also highlight the recently very popular brick with the "aging" effect. It makes lovely semi-antique designs. For example, it can be a chic "old" fireplace. With the help of such an object, you can radically change the appearance of the interior, giving it a special style and chic.

How to choose?

When choosing the right batch of popular and durable red bricks, you need to pay special attention to the following important parameters.

- Dimensions. When choosing a red brick, pay attention to its dimensional parameters. So, standard options have dimensions - 250x120x65 mm, one and a half (modular) - 250 × 120 × 88 mm and 250 × 120 × 130 mm, narrow - 250 × 60 × 65 mm, thin - 250 × 22 × 65 mm. And also the mass / density of the selected material should be taken into account based on its structure (hollow or full-bodied).

- No damage. Examine the materials you select carefully. There should be no serious damage or chips on a high-quality red brick. In addition, such products should not have a pale pink tint - this will indicate that the products were not fired correctly. You should hit the brick - the sound from the blow should not be muffled.

- Strength. Make sure the brick you choose is strong and reliable. To test these properties, you can hit the element with a hammer. Low-grade options after these checks turn into crushed stone, elements of medium strength are broken into several small pieces after several blows, and high-strength varieties of such bricks only sparkle when struck.

- Defects. Take a closer look at the surface of the red brick. On the surface of these building materials, noticeable whitish stains are often observed, representing a marriage that occurs due to the emergence of soluble salts on the surface of building materials. The susceptibility of bricks to efflorescence cannot be determined by conventional methods. For this, special chemical analyzes are usually carried out.

- Conscientious seller. Experts recommend purchasing red bricks from trusted sellers who have a good reputation in your city. In addition, it is not advised to purchase too cheap batches, as they may be of low quality.

Do not skimp on buying red brick if you plan to build a really high-quality and durable building.

For how bricks are made, see the next video.

The comment was sent successfully.