How to process a brick and how to do it?

Brick is a porous material, and therefore, when moisture gets into its structure, it destroys the masonry from the inside.

Special products for processing bricks provide additional protection against external influences and moisture. Such processing is needed to increase the service life of structures that are lined with bricks. It will also help to avoid the appearance of cracks, fungal deposits and deterioration of the characteristics of the structure. The compounds penetrate into the brick and activate there reactions against mold and dampness.

What is processing for?

The seams are the weakest point in the masonry. It is through them that moisture penetrates inside, and during frosts, water freezes. There it expands and acts on the bricks, causing the material to collapse. Also, some types of bricks can absorb moisture through the pores, which does not have time to dry and remains inside, as a result of which microcracks and chips appear, which also leads to destruction. To protect the brick from corrosion, experts recommend treating it with special compounds and carrying out hydrophobization.

The usual protective composition consists of iron oxide, purified water and binding agents that can penetrate the silicate and enhance its properties. The binder in such a liquid is potassium silicate, which is capable of interacting with salts. This helps to improve the protective properties of ceramic products, protects them from UV exposure and mold. Also, protective compounds improve the appearance and color of the brick.

The compositions increase the resistance of the wall to frost and eliminate the possibility of chips or cracks on them. At the same time, the stone does not lose vapor permeability.

Advantages and disadvantages

Impregnation makes it possible to protect the base from moisture and does not allow it to penetrate into porous structures. When processing the material with such a composition, a film is formed on it, which does not allow the development of fungus and mold.

The benefits include:

- preservation of the ability of the brick to pass air;

- protection of the material from delamination, which prevents it from losing its appearance;

- crack protection;

- increased corrosion resistance;

- environmental Safety;

- preservation of color, texture and structure of the stone;

- protection against dirt and dust on the surface;

- improvement of the thermal conductivity of the wall, which affects the reduction of heating costs.

The disadvantages include the fact that such mixtures are not cheap, and they will have to be applied periodically to the surface, which will require additional time and money.

Views

There are several types of penetrating waterproofing, among which the following can be noted:

- acrylic one-component;

- two-component silicone;

- lacquer;

- water repellents.

There are various types of biocidal impregnation for masonry and house facades.

Wet brick impregnation

The so-called liquid glass for waterproofing with a wet effect consists of silicone, which not only prevents water from entering the walls, but also protects against dirt, as a result of which the surface is easily cleaned of formations and becomes brighter. After processing the walls with such a composition, they acquire resistance to moisture, and the effect of a wet stone appears on them. The treated wall will always look fresh and damp, but in reality it will always be clean and dry.

Currently, such protection against water penetration is considered the most popular.

Knauf oil

This composition is made on the basis of oil from a German concern. After application, the mixture does not leave streaks, and also does not impair the vapor conductivity of the material, as a result of which moisture is naturally removed from it, which protects against fungus and mold. Therefore, the composition does not allow moisture to penetrate into the walls, improves the color and brightness of the finish.

Such impregnation is used both for the basement, walls in the bath, and for the foundation.

Antiseptics

They help protect walls from moisture, strengthen them and are used to prevent bacteria and insects from growing in masonry. The solution is mixed with water and applied to objects by spraying. It can also be added to building mixtures at the stage of building an object.

The service life of the composition is 10 years, after which the procedures must be repeated.

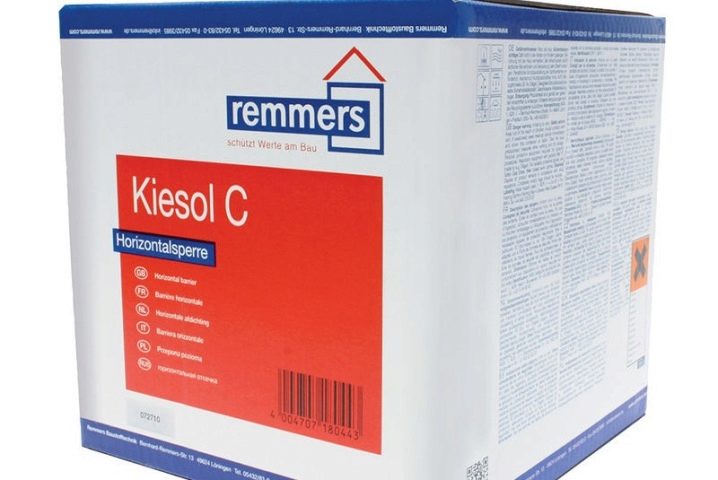

Remmers Blend

A mixture from a German manufacturer improves the water-repellent properties of brickwork, is durable and quality. Also prevents dust and dirt from forming on concrete surfaces. The product dries quickly and forms a transparent film.

Belzona Blend

It makes it possible to protect the object from all types of negative factors. Prevents corrosion of the silicate base, increases the service life of structures and prevents their rapid wear. Also protects against industrial pollution and ultraviolet radiation, can be applied to stone, concrete, cement and other surfaces.

If it is not possible to buy such products in the store, you can prepare them yourself. To do this, take vegetable oil and heat it over a fire, adding drying oil. Processing with such compounds is also carried out in two layers, each of which must dry for at least two days. If you prepare such mixtures correctly, then they are not inferior in quality to the factory ones, but the only drawback is that they will dry longer.

Before using these components, you must also prepare the base. Why do you need to clean it from dirt and let it dry.

It is necessary to start work on a warm day. If there is already damage on the walls, then they need to be repaired. For this, you can use special tools.

At some points, brick walls will need to be protected from efflorescence, which appear after a certain time on the brick surface. Such white stains not only spoil the appearance of the structure, but also indicate the slow destruction of the mortar and the masonry material itself in the wall. To protect against efflorescence, various preparations are used, which differ in their composition, but before application it is also necessary to prepare the surface.

When the first plaque appears on the wall, it must be quickly removed, since mold may appear in those places in the future. In this case, it is also effective to use silicon-based water repellents. These compounds are often used at the construction stage, adding them to the solution, which increases the resistance of the masonry to frost and improves its characteristics.

All these funds are sold in banks. One liter of the composition is enough for 150 square meters of base. To do this, you only need to dilute the composition in water in accordance with the instructions and apply to a dry cavity.

The walls can be pre-degreased and treated with antiseptics. You can do the work yourself, as it does not cause difficulties. The impregnation is applied in a thin layer to the surface and allowed to dry for 10-15 minutes. Repeat the procedure if necessary. Such protection can last up to 10 years.

Wind can also be a factor in the destruction of masonry, which will blow out mortar and destroy bricks. Such destruction does not occur immediately, but can last for decades. High buildings usually suffer from wind, where there are air currents that vary in temperature.

It is temperature changes that can cause the rapid destruction of masonry, and therefore it is necessary to process the surface. Water repellents are also used for this, which improve the characteristics of the wall and prevent it from collapsing. To carry out surface treatment using the above means you need to stock up on materials and tools, including:

- hoses;

- formulations for mixtures;

- rollers;

- antiseptic agents;

- ladder.

The better the protection of the masonry from external negative factors is made, the longer the structure itself will last. All factors affecting the wall negatively affect it, and therefore it is not worth delaying the processing process. It is necessary to carry out such procedures immediately after the construction of the house.... After hitting the surface, the reinforcing solutions penetrate into the material to a depth of 2 cm and form a thin protective layer there. It prevents parts of the masonry from breaking off and prevents water from penetrating inside, forming a crust.

The protective layer can resist nitrogen, nitrates and other components, and also prevents dirt or dust from forming on the surface. The product works effectively at temperatures from minus 60 to plus 200 degrees... The solution does not leave behind an unpleasant odor and is safe for nature or humans. Such mixtures are removed from the surface by rough processing.

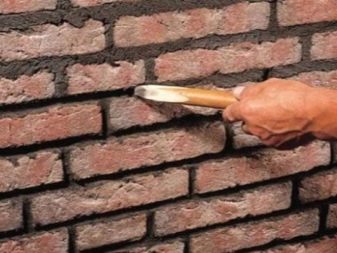

Another way to protect against destruction is to seal the seams. This gives the wall not only a finished look after brick laying, but also prevents moisture and other negative components from getting into the seams.

After grouting, it is recommended that these places also be additionally treated with water-repellent mixtures, which can be bought in a store or use ordinary sealant for these purposes.

How to process?

To cover a brick wall with any moisture protection compounds, it is necessary to prepare. Each brick can be impregnated, but if there is not enough time for this, sprayers can be used. All work is carried out in a specific sequence:

- cleaning walls from dirt;

- biocidal treatment against mold and mildew;

- primary coating of the bases with the composition;

- secondary coating;

- water repellent coating.

The surface of the sand-lime brick must be treated twice and a small amount of the composition must be applied in order to avoid smudges. All work is carried out in protective equipment outside the buildings. If the formulations come into contact with the skin, they must be rinsed with water.

See the following video for applying a water repellent to a brick.

The comment was sent successfully.