Chimneys for fireplaces: important nuances and useful recommendations

With the help of a chimney, combustion products are removed from the room. If the installation technology of this device is violated, the fireplace will not work correctly. This article discusses the important nuances of installing a chimney and useful recommendations for its operation.

Peculiarities

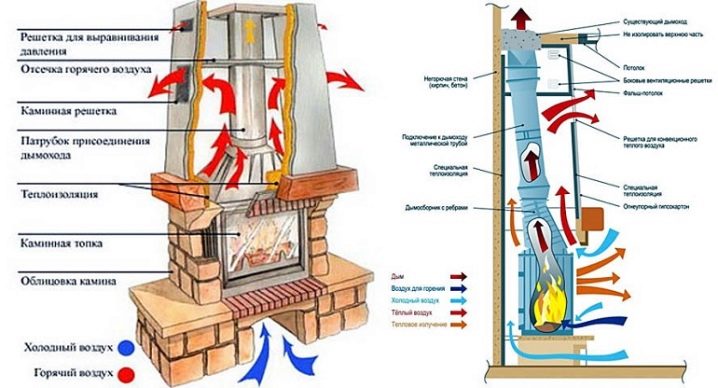

Burning fuel in the fireplace produces caustic products that must be removed. For these purposes, a chimney is provided in the heating device. Without this device, the operation of the entire furnace is impossible. Its work depends on the amount of oxygen in the fireplace insert. A system with maximum power can be obtained only under the condition of optimal air saturation. Excess or deficiency leads to malfunction.

The chimney is a loop-back system. Combustion products pass through the chimney into the air, clean atmospheric air enters the chimney. The recruited oxygen is heated and maintains combustion. The cycle repeats until the fuel runs out. In order for the chimney to serve for a long time, it is necessary to take into account all technological points during the installation process. You need to get a system of maximum strength and reliability.

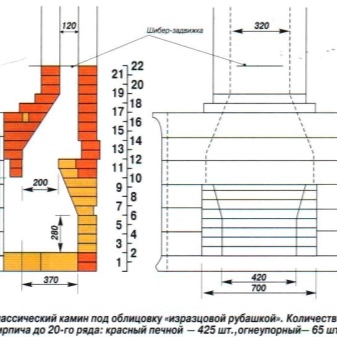

The most popular type of construction is a brick pipe. Such a fireplace device rests on a foundation, the role of which is played by a base plate or load-bearing wall. Masonry is carried out only with the use of lime-sand mortar. In a checkerboard pattern with a step of at least 30 centimeters, the chimney pipe is anchored. Anchors are deepened into the wall by 20 centimeters, the cross-section of the reinforcement should reach one centimeter.

The stability of the structure can be increased with reinforcement. The chimney is lined with a mesh with cells of 150x150 mm. It is also necessary to strengthen the ventilation pipes, creating a single reinforcement complex. When installing the structure, you should strictly follow the rules for assembling the furnace.

The brick chimney has a short service life. The structure can be operated for no more than 10 years. Brickwork is not resistant to temperature fluctuations during cold periods. Condensation also has a negative effect on the system. The efficiency in such chimneys is less than that of analogs with smooth walls. You can increase the life of the chimney by installing steel pipes.

Requirements

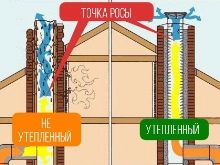

The chimney for each stove is installed taking into account the same requirements. It is necessary to avoid freezing the pipe, therefore the masters recommend installing the system in a warm part of the room. The pipe material must be resistant to contact with combustion products. A corrosive environment inside the system can destroy the flue gas outlet from the inside, therefore, special attention should be paid to the choice of internal coating. The surface should not be rough, as ash and ash can accumulate in the depressions and interfere with air circulation.

The chimney design includes two main elements - a pipe and connections.

A correct chimney must satisfy several requirements.

- Fire protection. To protect the structure from overheating and fire, a special substrate is mounted on the floors. The walls are sealed, and they try to eliminate the gap at the junction of the chimney and the walls. These rules must be followed during the installation of the structure.

- Traction. Air circulation must be good, therefore it is important to correctly calculate the dimensions of the pipe. If the length of the chimney reaches five meters, then such a device is considered constructively competent. Good draft is the main function of any fireplace.

- Sealed connections. The chimney must be of one piece construction. Violation of the tightness leads to a violation of the operational properties of the furnace. Combustion products will not be completely discharged into the environment; instead, gases will enter the room and harm the health of residents.

- Matching the type of material to the type of fuel used. It is important to install a pipe that can withstand the effects of combustion products.

- The minimum number of internal partitions. Condensation must not form inside the chimney. Smoke temperatures are maintained with decreasing vertical obstacles. This ensures constant heating of the inner surface of the pipe and the elimination of moisture.

Views

Chimney structures are divided according to the method of installation, material of components and location in the room. Among the chimneys, built-in options are distinguished, in which the shaft has a vertical arrangement, and the combustion products are removed without much difficulty. This type is considered to be the most rational in terms of material consumption.

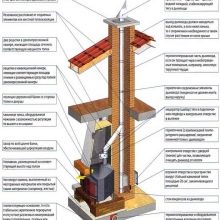

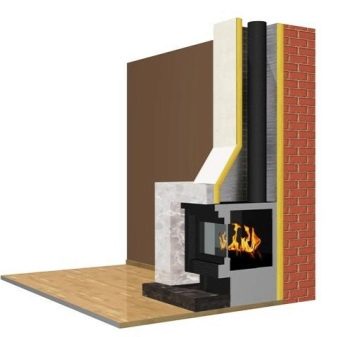

The chimney of a suspended structure is mounted to the ceiling or the load-bearing part of the roof. Such structures are assembled in a ready-made room, but with a pre-drawn layout of the chimney. When choosing a material for this system, it is necessary to give preference to metals. This material is quite lightweight, so it will not create unnecessary load on the floor.

The device based on the hearth differs from analogues in that it is installed directly on the base of the building. The heavy weight of the structure does not allow the system to be lifted. When designing a fireplace with a similar device, additional reinforcement of the floor of the room is required. It is not recommended to place this heating system on logs or cold floors without a reinforcement mesh.

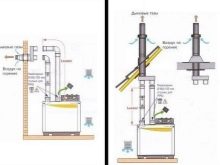

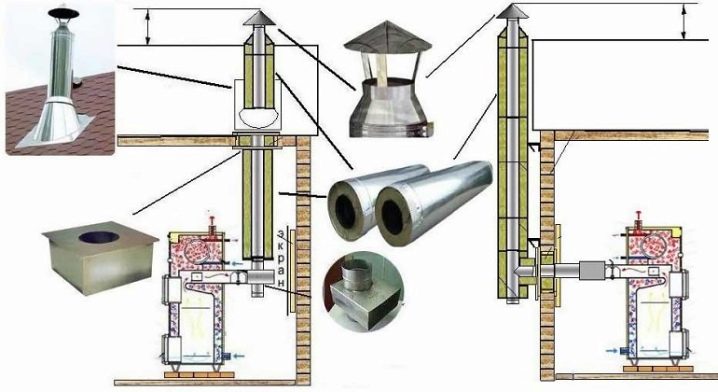

According to the constructive decision, the craftsmen distinguish double-circuit chimneys. The system is based on a pair of pipes with different diameters. Such coaxial chimneys can be easily obtained by immersing a narrow pipe inside a wide one and securing them with jumpers. The axis of the wider part should coincide with the axis of the narrower one. This design is considered the safest and most fire resistant. Installation of the structure is not particularly difficult, therefore it is suitable for novice builders.

Depending on the type of material used, brick structures, steel pipe structures and metal chimneys can be distinguished. The first type involves the use of several types of bricks. This type works predominantly with solid fuels. If you try to burn damp wood in a brick oven, the fireplace may deteriorate.

Steel pipes are distinguished by their stainless properties. Such structures have a relatively low weight and reliable corrosion protection. The main disadvantage of pipes is the high price. Ceramics belongs to the same price category, and its installation requires additional costs. It is important to know that the lifespan of ceramic devices pays off its cost.

Dimensions (edit)

Calculation of the correct dimensions of the chimney largely determines its operation and service life. The diameter of the flue duct must correspond to the firebox branch pipe. The section of a closed firebox usually reaches 200 mm, and in the case of a rectangular entrance - 270x140 mm. The open firebox has a diameter of 250 mm. The ratio of the diameter of the chimney in wooden stoves to the firebox is taken to be 1: 10. If the cross-section of the pipe is square, then the ratio decreases to 1: 1.5. Heat output in systems should not be less than 300 kcal per hour of operation. In this case, the section of the pipe must be taken 140x140 mm.

The height of the chimney depends on the technical characteristics of the material used in the installation.The structure of the building also influences the dimensions of the pipes. The height of the chimney is directly proportional to the draft force. Masters recommend installing a large chimney, while the height of the structure should not be less than five meters. Otherwise, smoke may start in the room.

The excess of the pipe over the roof surface must be more than 500 mm. This indicator is fixed by regulatory documents. The dimensions of the chimney must be taken into account in the process of creating a room project. It is forbidden to install such a heating system in a room with an area of less than 15 squares. In small rooms, there is insufficient air circulation.

Materials (edit)

Of bricks

The brick chimney is considered the first among analogues. The installation of such a system requires compliance with many rules and taking into account the nuances of masonry, so the work should be entrusted to professionals. This type of structure is being built together with the house, which saves on foundation construction. The dimensions and location of a brick fireplace are taken into account during the construction of the building, which minimizes installation errors.

The brickwork is fixed with admixtured cement. You should not use clean cement slurry, as it has poor flow capacity. Combustion waste will accumulate at the joints in the absence of the possibility of an exit. The soot build-up will roughen the pipe surface, resulting in poor draft. Such a fireplace will quickly fail and will require additional repair work.

Of steel

The use of stainless steel pipes allows for a lighter construction. Craftsmen prefer to use the sandwich construction described earlier. Steel pipes are reinforced with mineral wool, protecting the coating from aggressive environments and temperature loads. Stainless steel provides high traction due to good cross-country ability. Steel walls have low roughness, so soot does not linger in the pipeline.

The disadvantage of steel is its low stability. The design requires additional strengthening of the base and strengthening of the system itself. In addition, stainless steel cannot be used in wooden houses. Due to its high thermal conductivity, steel can quickly overheat.

It is unsafe to be in such a room because of the risk of fire. The metal pipe is in harmony with the interior only in rare cases.

From ceramics

Ceramic chimneys are easy to install and have a long service life. These systems are fireproof and therefore minimize the risk of fire. These designs are available in limited sizes. Each type has its own assembly technology. Fragments of the system are multi-layered, therefore they do not require additional protection with insulating materials. In such structures, there is a constant heat removal, since special channels are located in the shell.

The joints of the elements are filled with refractory mastic. The finished structure is installed in the wall without requiring additional reinforcement. The system installation process is straightforward. It is important to know that a gap of 5 centimeters must be left between the chimney and the wooden wall. If this cannot be done, then a steel pipe must be inserted into the fireplace. It will reduce the thermal load on the boards.

How to choose?

The dimensions of the chimney are determined by the dimensions of the stove. The pipe cannot be installed without a hood. Its installation takes place near the location of the chimney in accordance with the regulatory documentation. This device increases traction and provides additional air exchange. To increase the power of the fireplace, you can additionally install ventilation ducts. Such devices will increase the time of heat transfer to the room, regardless of the number of storeys of the building.

The thickness of the pipe depends on the choice of fuel. For a fireplace operating on liquid or gaseous fuel, choose a system with a thickness of at least 0.6 millimeters.The use of firewood and coal is possible when installing a pipe with a thickness of 1 millimeter or more. Such masonry can withstand fuel combustion temperatures above +250 degrees.

An outdoor fireplace requires reinforcement with insulating material. A set of heaters protects the side chimney from the negative effects of low temperatures and high humidity. The internal chimney does not require such measures, therefore it is easier to use single-wall components for its installation.

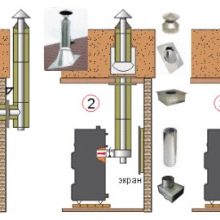

The chimney umbrella is an equally important part of the chimney. It protects the pipe from clogging by leaves and other environmental particles. Umbrellas also protect the fireplace from fire. Entrained particles can ignite and disrupt the operation of the system. In addition to its protective function, this element plays an aesthetic role. An umbrella of an unusual shape will give a zest to the structure.

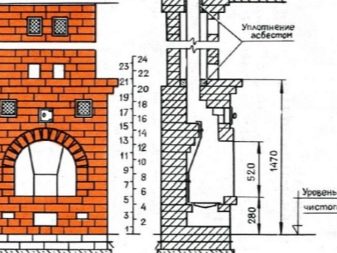

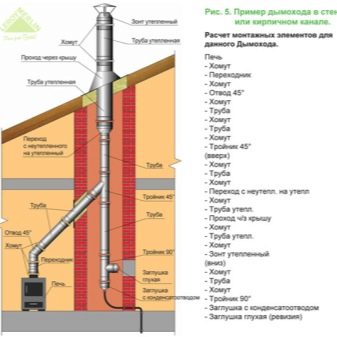

Installation

Chimney installation is carried out individually for each case. The assembly scheme depends on the choice of material. In brick structures, the chimney is located directly on the foundation. It is important to preserve the pattern and rows of brickwork. Such designs are accompanied by the installation of a chimney, a mop and a head. The connections must be made under the supervision of a professional.

It is also important to place the ceramic chimney on the foundation. Parts of the pipe must be securely fixed. The joints are additionally treated with a protective compound. Ceramic chimneys require additional installation of some devices: tee and revision. Clamps are used to securely fix pipes and eliminate unwanted displacements.

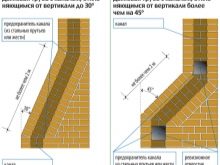

Sandwich pipes are installed using brackets. The required angle of inclination provides retraction. Choosing the wrong angle will disrupt air circulation. An additional draft compensator can be installed to enhance the bend.

Another name for the device is fungus. At the base of the device there is a metal box to which a special skirt is attached. The compensator works better when solid fuels are burned.

The deflector has a similar appearance and is also designed to increase traction. Air acts on the shell of the structure, creating the necessary pressure. Part of the flow enters the structure, additional circulation occurs, during which the combustion waste is quickly removed from the pipe cavity. In some cases, such a device is indispensable. Draft in the heating device prevents the accumulation of chemical waste and their release into the room.

The chimney must be additionally enclosed with a layer of insulator if its hot surface is in contact with walls unstable to high temperatures. During the installation of pipes, kinks should be avoided, since good circulation takes place only in strictly vertical channels.

The main outlet structure is connected to the furnace by a horizontal pipe, but its length should not exceed one meter.

The most common mistakes

To increase the service life of the chimney, it is necessary to take into account possible violations during the installation process and the causes of breakdowns.

- Before directly installing the pipe, it is necessary to draw up a drawing of the future structure. It is possible to organize construction work only after the plan has been certified. Otherwise, circulation may not take place and smoke will enter the room.

- Pay close attention to the functionality of the pipes in sloping areas. A pipe at an angle of 45 degrees or more will not provide the required air outflow. Such moments should be avoided.

- It is also worth paying close attention to the joints when joining the structure. If the pipe is not sealed, the heated air will lead to the destruction of the entire structure. The seams must be additionally reinforced with fire-fighting mastic. If the crevice is smoking, the structure must be disassembled and reassembled.

- Often, masonry mortar is destroyed in brick structures.This can be due to improper composition, dampness, or high temperatures. The masonry should be strengthened.

- It is also important to monitor the condition of the insulation above the headband. Water has a negative effect on the functioning of the entire structure, therefore, leaks must be monitored and eliminated at the initial stage.

- The under-roof area around the pipe is often damaged by condensation and moisture. If fungus and mold are found, the damaged layers should be carefully removed and replaced with a new coating.

- The head is treated with concrete to enhance its strength. Obsolete seams are cut to a depth of 3 centimeters and also updated. This should be done carefully. A deeper cut can damage the internal structure of the pipe and compromise its tightness.

Cleaning

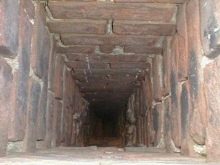

Chimney clogging can be caused by the accumulation of combustion products. Soot clogs up in the cracks and unevenness of the masonry, creating a barrier to air circulation. Smoke can enter the apartment and have a negative impact on residents. This tube must be cleaned. This can be done both with the help of a specialist and on your own. The work does not pose a particular threat and does not take much time.

Mechanical cleaning of the pipe cavity must be carried out both in the house and outside the building. Hard metal brushes can be used to remove soot layers. A massive weight is tied to the end of the brush on a cable. Under the influence of gravity from the core, the brush is lowered without unnecessary effort. With a gentle movement, the rope is pulled towards itself, and the device rises, cleaning the walls of the pipe. It is important not to make sudden movements so as not to damage the structure.

Cleaning should be done regularly. Otherwise, the soot will form a dense layer that cannot be cleaned on your own.

In the next video, the stages of installing a brick chimney are waiting for you.

The comment was sent successfully.