How to choose fireplace accessories?

At all times, people have used different ways to keep warm. Fire and stoves first, and later fireplaces appeared. They perform not only heating, but also a decorative function. Various accessories are used to ensure full functionality of the fireplace.

Views

The following types of standard accessories are distinguished:

- poker;

- broom;

- scoop;

- forceps.

The poker is designed to change the position of firewood in a fireplace or stove. It can look different. The simplest option is a regular stick made of metal with a bulge at the end. A more modern look is a piece with a hook, and special aesthetes make it in the shape of a spear.

The tongs are the most advanced analogue of the poker. This device allows you to carry out the transfer of firewood or coal. Most often they are used when cleaning chimney waste located near it. Under standard conditions, tongs are also used when transferring lost coals that have left the fireplace for any reason.

The scoop is used in conjunction with a broom when cleaning the area around the fireplace.

There are two ways to store such a set:

- placement on the wall;

- placement on a special stand.

In the first version, a bar with hooks is attached to the wall, and in the second, a base is placed on the floor, to which the stand is attached. Hooks or several arcs are attached to it, with the help of which each of the elements of the set takes its place.

There are also additional fireplace decor items. These include:

- a stand on which firewood is stored;

- a container in which matches or a fireplace lighter are stored;

- security elements (screen or mesh);

- means of ignition of fire (lighter and fireplace matches).

The lighter is considered more reliable and speeds up the ignition process.

DIY making

Of course, we will not make a lighter and matches with our own hands, but it is quite possible to make the rest of the decor elements ourselves.

Most often, the following types of material are used for their manufacture:

- copper;

- brass;

- steel;

- cast iron.

The most common are cast iron and steel options.

There are two types of accessories:

- electrical;

- fiery.

Brass and copper are commonly used to create electrical items. It should be noted that such accessories will only have a decorative function. In addition, they will be covered with soot and soot. So, when using accessories made of brass and copper in a brick fireplace, they will require constant cleaning.

You don't have to spend a lot of time choosing a scoop. As a rule, the usual fixtures are used.

Consider the process of making a scoop:

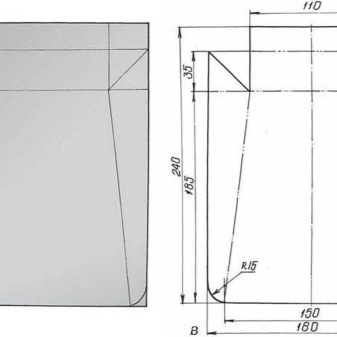

- When creating it, it is customary to use sheet steel, which has a thickness of 0.5 mm. It is used to make the main part of the scoop.

- Next, a steel sheet of 220x280 mm is taken. From the side with a size of 220 mm we retreat (from the edge) 50 and 100 mm, and then we put two parallel lines on our sheet.

- After that, at a distance of 30 mm from the edge on the first line, we draw marks.

- We apply the same markings along the edge of the sheet, and then connect them together. Corners are cut along intersecting lines.

- Let's move on to working with our second line. We also apply markings on it (as on the first line). It should be noted that all marking lines are drawn with a metal rod, which must be sharpened.

- Let's go directly to the manufacture of the scoop. We take the anvil and planks. With their help, from metal we bend the back of the sheet along the second of the lines we have drawn.

- The lines should be counted from the edge of the side where the corners were made. The sides of the sheet must be bent, and the upper part of the back wall must be bent so that it fits snugly against the back wall.

First, make a paper version of your scoop. This will help you understand how convenient the design will be to use, and will also allow you to take into account all the shortcomings.

Let's move on to working with the pen. The handle must be at least 40 cm long.

There are two ways to make this fixture:

- by forging;

- fabrication using sheet metal.

If you do not want to spend a lot of time and effort, then the second method will suit you much more.

Forging

Consider in stages the process of forging a handle for a fireplace.

- First you need to take a metal rod with a square cross section, and then heat it in an oven until it turns red.

- We leave the heated rod for a while so that it cools down.

- Then we put the end of the rod in a vise, put on a pipe that is shorter than the end clamped in the vise.

- After that, using the gate, the workpiece is twisted around its axis several times.

- After that, it is necessary to sharpen one end of the cone with a height of 6 to 8 cm and the other end with a size of up to 15-20 cm.

- The end, which has the greatest length, is folded back until absolutely exact parallel is reached with the main part of the handle.

- After that, work is carried out with the second end of the structure, placing it on the anvil and flattening it so that the leaf shape is achieved.

- Then we make holes, and also bend the part until the contours of the scoop are reached.

- At the end of the work, the pen is placed in oil, after splitting it. Next, just connect both parts, getting the desired result.

Sheet metal

The second way looks like this:

- The handle is made in the form of an ellipse by bending two longitudinal edges of the sheet. The second end does not bend - two holes are made on it. Having done them, we make a bend, reaching an angle of 70 to 90 degrees.

- The same holes are made on the back of the scoop. After completing all the manipulations, both parts are fastened together, for example, with rivets.

Making forceps

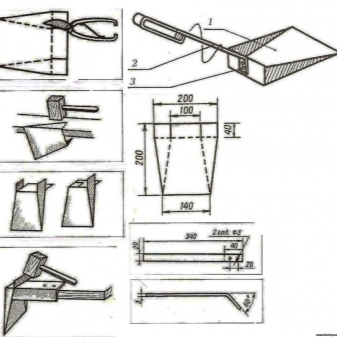

Tongs can look like scissors or tweezers.

Consider an example of making tweezers:

- A strip of metal is taken, heated in an oven to a state of redness. After that, it is left for a while to cool completely.

- If the strip is long, fold it in the middle. In this case, the bend itself should have the form of a circle, from which two straight lines are located on both sides. If you have several short strips, then they are connected to each other using special elements, for example, rivets.

- Only after fastening is they bent. Next, you need to twist each of the ends. After re-heating, we leave our structure to cool down.

- At the end, we paint the object in the color we need.

Poker and broom

To create a poker, metal is processed in the same way as for making tongs.

However, this work has a number of distinctive features:

- We take one end of a circle-shaped rod, and then, stretching it out onto a rectangle, we need to make a small curl there. Further, on a special device - a fork, you need to bend the handle.

- A similar curl is created at the other end. After that, on the previously prepared part, it is necessary to bend so that it is located perpendicular to the main part of the poker, which is already in our set. A similar bend is made on the fork.

- We twist.

To work safely with a poker, its size should be between 50 and 70 cm.

We will not be able to make a broom completely.It will turn out to make only its handle, and the soft part will have to be purchased. It should be borne in mind that the pile must be purchased with fire-resistant properties. A special fireplace vacuum cleaner can be an excellent replacement for a broomstick.

Firewood stand

The main materials for the manufacture of fireplace coasters are:

- pine boards;

- plywood;

- metal strips;

- metal rods.

Consider an example of making a wooden stand:

- An arc with a size of 50 to 60 cm is made from pine boards. It is necessary that one of the ends is wider. It needs to be positioned over the narrower end.

- On each arc, it is necessary (evenly along the length) to apply five holes. They are placed on the side.

- Next, we make crossbars in the amount of four pieces. Two with sizes from 50 to 60 cm, and the remaining two - from 35 to 45 cm. In this case, grooves and holes are made in the crossbars made by us at the ends of narrow arcs.

- After that, the crossbeams must be fixed in the holes made at the ends of the arc, and metal rods should be placed on the holes made on the sides.

- Next, we make the back of the stand from the rods. The plywood sheets are placed in the grooves.

- Ten holes are made evenly along the entire length of our strip. Next, bend our metal strip in the shape of the letter "P". It should be noted that the ends should look like arcs. Using screws, fix the strip between the walls.

Beautiful wrought-iron firewood boxes look especially impressive. Many Italian manufacturers are known for such products. They look great in antique interiors thanks to the luxurious forging elements.

Fur to fan the fire

This tool greatly facilitates the process of starting a fire.

It is made from:

- pipes or nozzles;

- a pair of wedge-shaped wooden planks;

- accordions;

- pads with a valve.

You can watch how to make a screen for a fireplace with your own hands in this video.

The comment was sent successfully.