How to make a DIY wood chopper?

After cleaning the garden area, there are enough branches, roots and other plant debris. Special shredders do the best with it, but purchasing such a model in a store requires a significant amount. A good owner should make the unit on his own from improvised elements.

Features of homemade models

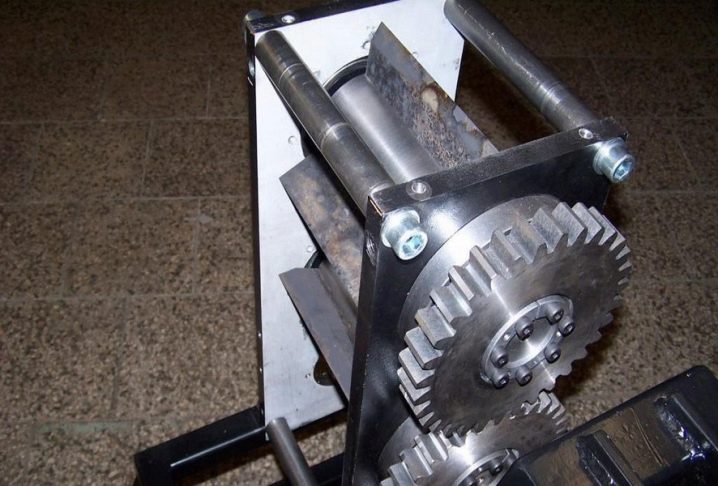

Any shredder (both homemade and purchased) should be composed of several basic components:

- a steel frame on which all components are fixed;

- electric or gasoline engine;

- cutting mechanism;

- protective casing;

- main gear.

In addition, you cannot do without a couple of containers: the processed garbage will be placed in the first, and the resulting chips will be stored in the second. Homemade models differ in the cutting mechanism, and the rest of the elements are the same (only with different sizes). Chipping of branches can be carried out using 20 or 30 circular saws, which are equipped with carbide tines. Then it can be a combination of sharpened carbon steel knives attached to the shaft. Garbage will be placed at right angles and chopped with knives, of which there are from 2 to 6 pieces.

The next version of the grinder can be called a disc crusher, into which branches are placed at an angle of 30 to 45 degrees. In this case, the knives are mounted on a steel circle fixed to the shaft. In more complex variations, there are two shafts rotating in sync. The knives converge at one point and crush the waste. In this case, the wood should be folded at right angles. Circular saws are recommended to quickly and easily produce miniature wood chips from waste. An aggregate like a jointer is relevant when processing thin branches to obtain a larger fraction. Finally, a disc crusher is suitable for cutting branches that are more than 5 centimeters in diameter.

Materials and tools

Most of the shredder's components can be selected from household supplies. For example, the frame is perfectly assembled from metal corners, channel and pipes. The electric motor, as a rule, is bought or taken from a mini-tractor. The cutter used must necessarily have large teeth, and the circular saws must have a diameter of 100 to 200 millimeters. If the work takes place with the shaft, then the gears are purchased in the amount of a couple of pieces, the same applies to the pulley, as well as to the shaft itself - there should be two of them. Knives can be made from vehicle springs if you have a milling machine.

From the tools it is worth preparing a perforator, wrenches, a grinder, as well as a welding device and a set of fasteners.

How to make a chopper with your own hands?

To make your own chopper for giving, you will need to follow a well-thought-out scheme. First, the optimal design is determined, which may differ, for example, depending on the size of the waste - whether it will be small branches or large pieces of wood. The choice of design depends on the needs of the master and on what kind of waste he has to process. Of course, at this stage, drawings are made.

You should choose the engine, deciding whether it will be electric or gasoline. The gasoline engine is more powerful and is suitable for processing large wood.Since it is not tied to an outlet, it is easy to transport around the site, but the unit itself is quite heavy. The electric motor is weaker, and its function is directly dependent on the length of the cable. However, the advantages of the device include its low weight. Parts that require a lathe for their manufacture are made by professionals, and the rest are simply selected from the materials available on the farm.

No shredder can do without a frame. It is most convenient to make it from pipes and corners. The height of the structure should be selected depending on the height of the person who will most often use the device. The recommended width is 500 millimeters, and can be any length. The necessary rigidity of the frame can be given if a cross member is mounted between the posts. Finally, experts recommend adding wheels and a handle to the device, which will add convenience to the operation.

After the frame is assembled, the drive, cutting parts and belt drive will be installed. Finally, a protective casing and containers for waste and resulting sawdust are mounted. By the way, the belt drive is considered the most affordable and safest to use. If during intensive work the belt slips off, then this will happen without any negative consequences.

The power of the drive will determine how thick the pieces of wood can be processed. Recommended motor power ranges from 2.5 to 3.5 kilowatts. If the shredder is assembled for processing grass and knots, then a unit with a capacity of 1.5 kilowatts is also suitable. The processing of branches with a diameter of 2 centimeters can take place with an engine whose power ranges from 1.3 to 1.5 kilowatts. Such an engine can be removed from a vacuum cleaner, grinder or even a drill.

Garbage, the thickness of which reaches 4 centimeters, requires the use of an engine, the power of which is in the range of 3 to 4 kilowatts. The device can be taken from a circular, in this case it is recommended to borrow a frame from the latter. If the thickness of the branches reaches as much as 15 centimeters, processing should be carried out with a minimum 6 kilowatt engine. Gasoline engine performance ranges from 5 to 6 horsepower, which is typical for devices taken from motoblocks or mini tractors. There is no need for excessively high power in the manufacture of a shredder.

In addition, it is important to ensure that the blade shaft rotates at 1500 rpm. By the way, in the case of a unit with chopping knives, you can rely on the drawing of the cutter shaft for the jointer. We'll have to, however, change the diameters of the axles by pressing the bearings. The width of the working section can be reduced to 100 millimeters.

To create a disc grinder, you will need an engine, pipes, a metal sheet, the thickness of which is 5 millimeters, a hammer drill and wrenches. It is better to choose knives purchased from hardened steel, the creation of which is difficult on your own due to the need to use a forge. In this case, a pipe can be used as a support. A disc with a diameter of 40 centimeters is formed from the metal, holes are made in it for the shaft and knives. Next, the disc is mounted on the shaft and connected to the motor. In the final stage, the branch compartment is installed.

Powerful thick branches can only be processed with a two-shaft shredder. Its creation begins with the fact that two centered shafts are mounted on a frame placed vertically. Each shaft must be equipped with removable knives. The number of knives determines how small the chips are. A self-made device will be able to grind branches up to 8 centimeters thick.

The manufacture of a shredder is also possible from household appliances that have already become obsolete. The only requirement in this case is the presence of a working motor, which is supplemented with the required parts. The presence of a working grinder will greatly simplify this task. It is enough to pick up a large-sized container and make a hole from below through which the axis of the grinder is passed. The knife is mounted at the top and carefully fixed. It is important that during operation the cutting blade does not touch the walls of the container being used. Chopping branches should be carried out at the minimum speed of the Bulgarian machine.

The knot and grass shredder has its own specifics. Instead of powerful tines, a device similar to a cabbage shredder is sufficient. The cutting structure itself can be placed either in a bucket, or in an old pan, or in a box welded from sheet steel. Parts from ventilation systems are also suitable for this. Such a shredder will be lightweight and very convenient to carry.

From the washing machine

It is quite convenient to create a single-shaft unit from an old washing machine. In this case, the first step is to dismantle the activator, and the motor shaft is equipped with a knife. It is important that the size of the cutting unit is smaller than the diameter of the tank. A hole is cut in the lower part of the device through which the chips will fall into the attached casing. The principle of operation of a home-made device is somewhat reminiscent of an apparatus for grinding coffee beans.

From circular saws

The simplest shredder is made from circular saws. To create it, it is necessary to purchase from 20 to 25 circular saws equipped with tips from hard alloys. The knives are mounted on a shaft, and between them washers are fixed, the diameter of which is equal to a couple of centimeters. The thickness of the latter is in the range from 7 to 10 millimeters. The length of the cutting blade in this case will be equal to 8 centimeters. It is important that the teeth of adjacent discs are diagonally relative to each other, but in no case on a straight line. After the cutting device with bearings is fixed on the frame, you can mount the engine, tighten the chain and make a container into which the branches will be folded.

The frame is mounted from a corner and pipes or a channel, and a special stand for an electric motor is made below. It is worth taking care of its mobility in order, if necessary, to adjust the condition of the drive belt. On the cross members, supports for the ball bearings are made to secure the shaft. It is imperative to ensure that the axes of the motor and the shaft itself are parallel. The container in which the direct grinding of the branches will take place must be made of a durable material that will not suffer when pieces of wood cut into its walls.

Experts recommend that you additionally think about the support plate on which the branches will rest during the procedure. This passive knife should be made transformable in order to be able to produce chips of different sizes. For example, large pieces from waste can be used to heat a stove, and small pieces can be added to compost. By the way, when passing fruit tree branches through the shredder, it is recommended not to mix them with other waste. Stone and pome fruit varieties are also processed separately. The result is several excellent fuels for the smokehouse that differ in their aroma.

We must not forget about the capacity where the branches will be laid. A prerequisite is that the depth of the socket exceeds the length of the hand of the person using it. If this part is made in the right way, then it not only protects a person from damage, but also allows waste to be laid at a right angle.

From the walk-behind tractor

To turn an old walk-behind tractor into a chopping device, in addition to the main part, you will need knives, a shaft from an electric planer, a channel and a bearing, as well as sheet material. The work will be carried out using a welding machine, a hammer with a grinder, a drill and a set of keys. A channel is used as a base, on which the shaft, pulley and cutting blade are mounted. Then a metal bunker is attached to the shredder for receiving waste, everything is fixed on the walk-behind tractor.

For information on how to make a do-it-yourself wood chopper, see the next video.

The comment was sent successfully.