How to make a DIY garden shredder?

In the arsenal of modern gardeners and gardeners there are many different devices that simplify the procedures for caring for the site. Such devices include a shredder (or shredder). Such things differ in their structure and functionality. Thanks to a high-quality shredder, it will be possible to shred branches, leaves, and even small tree trunks without any problems. The shredder can be made by hand. Today we will analyze in detail how this should be done according to all the rules.

Basic structural elements

Before proceeding to the independent manufacture of a good and productive shredder, it is necessary to consider in detail what are the main structural components it consists of. Despite the fact that the drawing of such a device may seem very complicated to many, in fact, its structure is simple and straightforward.

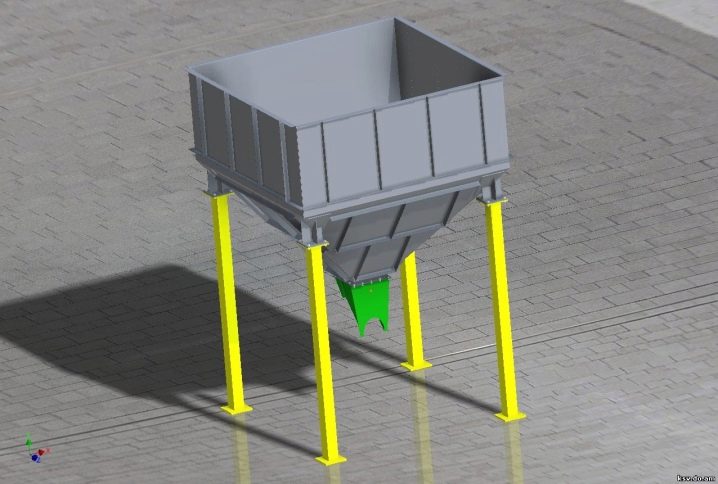

The body of the garden shredder is mainly fixed on a support, represented by stable wheels or legs, which make it easier to transport the unit. From the outside, this design looks the same as a cart with a handle. In the inner part of the body there is a special mechanism powered by gasoline or electricity, as well as the grinding system itself.

Based on the knowledge of all the elements of the indicated structure, it is possible to consider by what principle it functions.

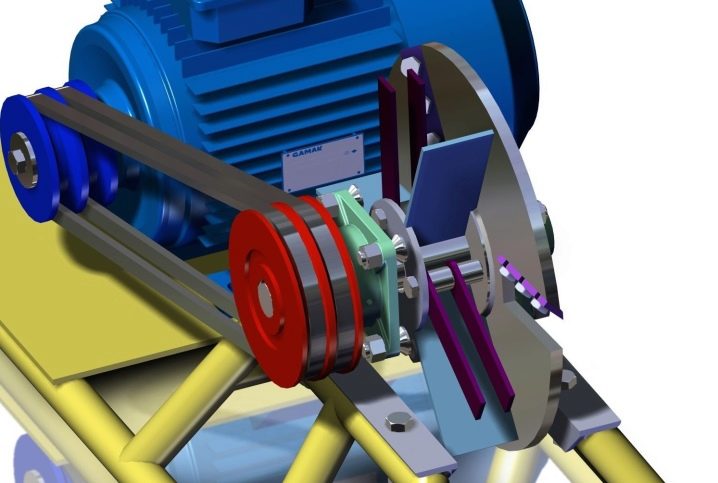

- On the shaft of the electric engine there is an attached milling cutter with knives, through which the garbage in the garden is shredded.

- The drive operates with the involvement of a belt and a transmission type device.

- All accumulated waste is sent to the compartment where the garbage is accumulated. There they are ground by the previously mentioned cutting element system.

- The chopped wood that is obtained at the exit from the device's container is often used by gardeners as a good compost.

Which engine should you choose?

As mentioned above, an efficient garden shredder can be built without problems on your own. It is very important to choose the right engine for such a homemade product. Most often, these devices contain electric or gasoline engines. Of course, each of these options has its own strengths and weaknesses, which must be taken into account when choosing them.

Devices equipped with an internal combustion engine are more convenient to use, because for their operation there should not be a source of electricity nearby. However, these copies are more expensive than electric ones, and their device is more complex. Therefore, many users prefer electric motors. They are both cheaper and simpler in design, and have a more modest size.

Largest cut limb thickness that a branch shredder can shred, is in direct proportion to the electric motor fixed on it, as well as the characteristics of the available knives.

- So, devices in which there is a motor up to 1.5 kW can grind sticks with a diameter of up to 20 mm without any problems. These options are great for fairly low intensity work.

- If an engine is installed in the shredder, the power of which is from 3 to 4 kW, then such a unit will be able to shred branches, the thickness of which reaches 40 mm.

- As for more powerful and efficient motors with a power of more than 4 kW, they are used to grind wood waste with a diameter of 7 to 15 cm.

To create a high-quality and efficient machine for shredding garden debris, it is permissible to turn to the installation of electric motors from a washing machine, grinder or other similar device.

If you want to make a shredder that will be aimed at an impressive amount of work, then it is advisable to give preference to more powerful electric motors, the power of which is at least 4 kW. If you do not want to install an electric engine and prefer gasoline options, then a unit with a capacity of 5-6 liters will be enough. with.

Materials and tools

Before starting work on creating a garden shredder, you need to stock up on all the necessary tools and materials. To carry out such work, you will need the following important components:

- circular saws - from 15 to 25 pcs.;

- motor - usually electric or gasoline is chosen, the choice of power should come from the goals that you assign to the future device;

- hairpin (or rod) m20, and to it washers and nuts;

- a pulley (a pulley from a VAZ generator is suitable), as well as a rather dense belt;

- bearings;

- metal pipes - it will turn out from them to build a strong and reliable frame;

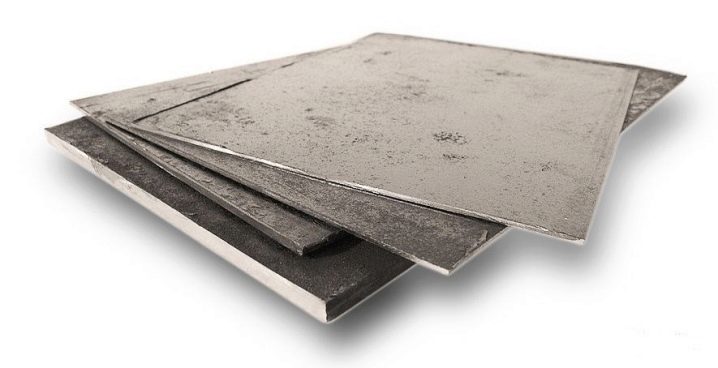

- metal in sheets for the construction of a bunker (a tank where the rubbish will be located);

- plastic washers - approx. 14-24 pcs. plastic washers - approx. 14-24 pcs.

How to do it yourself?

If you have purchased all the required materials, and with them the suitable tools, then you can safely proceed to making a garden shredder. Of course, you will need to prepare a detailed drawing in advance. Indicate on it all the dimensional parameters of the future design, mark the location of all parts present in the device. Do not neglect this stage - with a correctly drawn up drawing, it will be easier to make a high-quality reliable shredder.

There are several options for garden shredders. They differ in their design and are assembled in different ways. Let's consider several ways to make them.

Knife

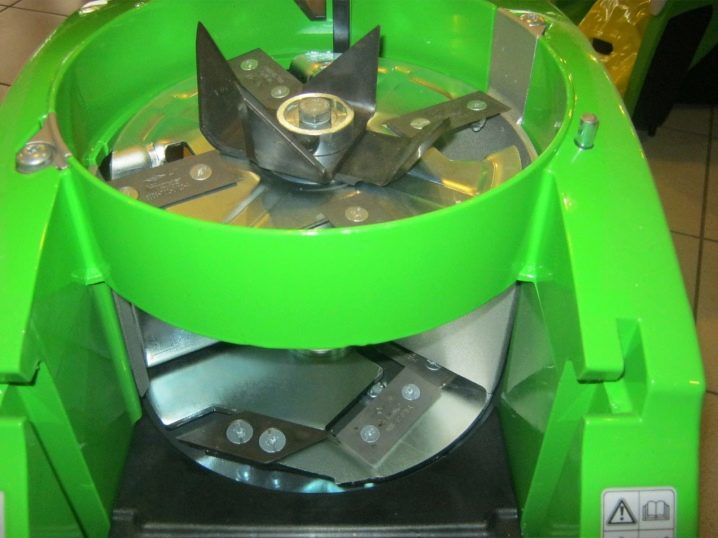

If you want to make a fairly simple shredder that is inexpensive, then you should make one from a disc with knives fixed to it. Also, the design of this device must include a frame and a loading container. It is quite possible to grind the disc and knives on your own or make an order from an experienced turner. Some users buy all the necessary items from specialized retail outlets. In the role of a drive, an engine from a cultivator is quite suitable. The frame structure and the hopper can be welded independently.

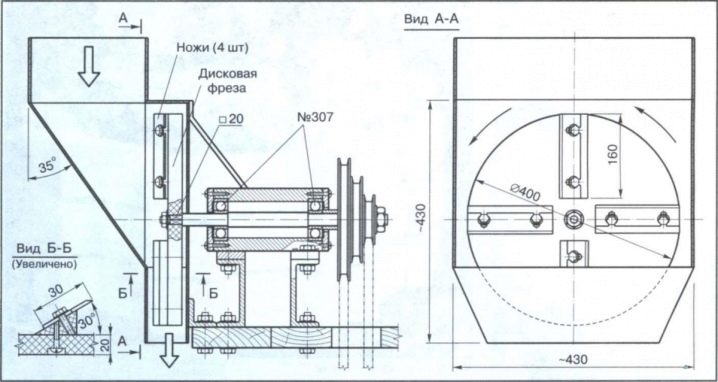

Based on how many knives are used and how they are placed, the fraction of the resulting mulch may vary. Below is a typical device for such a shredder. The order of work will be as follows.

- First, you need to purchase, order or prepare a disk with knives on your own. The sharpening angle of the latter should be between 35 and 45 degrees. The base of the knives should have holes for the bolts required to attach to the disc part.

- Set your knives correctly. Secure them using stops and bolts.

- Now you can proceed to cooking the shredder frame. Consider the fasteners and other components during this work.

- Then it will be possible to push the disc onto the drive shaft. Secure it there conscientiously.

- Then the feed hopper and the receiving hopper (if needed) for the processed mass should be welded.

- Finally, all the workpieces will need to be securely fastened to the frame.

The frame with all the components attached to it can be mounted on wheels. Then the entire device will become mobile - it can be easily moved around the site.

From the washing machine

A good shredder is obtained if you make it from a washing machine. Today many DIYers are turning to such technical experimentation. To carry out all the work, you will need to prepare the body and engine from the machine, an old saw, a bucket and other components will do, as well as fixtures / tools required to secure the structure. In this case, you will need to perform the following work.

- Make a side hole on the body of the old washing machine. It will be needed to exit already processed and shredded material.

- At the bottom of the container, using a special sleeve, it is necessary to securely fix the knives. They are often made from separate pieces of an old saw - a very simple and economical solution.

- As an engine, you can use an existing unit, which was previously present in household appliances.

- The receiving hopper for crushed raw materials will need to be fixed at the side hole made in the first stages.

As you can see, carrying out these works is very simple and straightforward. This does not take a lot of time and expensive materials.

From a circular saw

A good grinder can also be made from such a well-known tool as a circular saw. Devices in which a circular base is present are highly efficient. If you are planning to build such a shredder, then you will definitely need to change the standard discs originally installed on the cutting shaft. You will then need to attach a container to receive the recycled material.

You can also make a chopper from circular saws. To do this, you will need to order a shaft from an experienced turner, on which discs will be put on in the future. Of course, you will have to purchase the disc parts themselves. When assembling such a unit, you will need to take into account some of the nuances:

- the disks must be strung on the shaft in such a way that they are not attached closely, but through washers of 7-10 mm;

- the teeth of adjacent disks should not be located on the same line - they should be fixed in a chaotic or diagonal manner.

From a plane

Many do-it-yourselfers make reliable and practical shredders from specific planer parts. There are a lot of execution options using this tool. Let's consider one of them.

In combination with elements of an electric plane, a walk-behind tractor can be used. In a single combination, a rather powerful and productive machine comes out. In order to assemble it, you will need:

- electric planer knives;

- walk-behind tractor;

- pulley;

- shaft;

- channel;

- bearings;

- channel;

- metal in sheets (3 mm.);

- bolts;

- washers;

- nuts.

You can't do without such tools as:

- welding machine;

- hammer;

- Bulgarian;

- set of keys;

- drill;

- pliers.

Now we will analyze step by step how it will turn out to make a good chopper using cutting parts from an electric planer.

- First, you can weld the channel to the base, and then fix there a static knife and a drive shaft with knives from an electric tool (in this design, this part is one of the main ones).

- Secure the pulley to the shaft with the cutting unit. This is necessary so that the latter can be driven by torque.

- Next, you should weld and install the waste bin.

- Now you can set the component itself for grinding. Fix it on the front half of the walk-behind tractor. Beforehand, agricultural machinery can be placed on bricks or hemp to make it more convenient to work. Next, you should stretch the transmission (belt) onto the pulley.

This completes the manufacture of a garden shredder with parts from an electric planer.

From a drill

Many home craftsmen prefer a drill when making a garden shredder to washing machines and electric planers. The principle of operation of such a device will be similar in many respects to a vegetable cutter. To make a structure of this type, the following steps are required.

- Take an old stool. Drill a hole in it, its diameter should be 12 mm. On the other side of the stool, fasten the housing part with the bearing.

- Place on a stool and secure a bucket of suitable diameter with self-tapping screws.

- Insert the bearing into the hole. A shaft with steel knives installed will stand on it. Closer to the end half of the shaft at the bottom of the stool, attach a dual-mode drill using a keyless chuck.

- Send soft raw materials into the fixed bucket and start the electric drill. After meticulous crushing to the required fraction, the mulch will need to be removed from the container. Please note that a unit with such a device will only be designed for a small amount of waste and debris.

Special attention should be paid to all stages of making and sharpening the knife. Sharpening must be one-sided. The chiselled base should be at the bottom.

To chop freshly cut grass, it is advisable to use a knife that follows the shape of a diamond (the blades should be slightly rounded). Thanks to this feature, the grass will be able to slide freely along the cutting edge of the knife without wrap around it.

Homemade equipment operation

From all of the above, we can come to the conclusion that making a garden shredder with your own hands is easy and simple. Almost any user can handle this. However, it is important not only to know how to assemble such equipment, but also how to operate it correctly. Consider the intricacies of using a homemade device.

- You should only start chopping branches if you are wearing goggles or a mask. You will need a headgear and a tall pair of shoes. It is advisable to send the branches to the car with bare hands or with gloves, but very narrow and tightly fitting on the hands.

- Do not put your hands below the opening of the hopper for loading waste. If necessary, it will be possible to push through the rubbish with a further batch of rods. It is permissible to use a special stick for this, which has branches at the end.

- The dimensions of the branch that you send for processing should not be more than half the center-to-center distance between the shafts. When selecting wood particles that you plan to dispose of, it is very important to take into account the knives used in the technique.

- Experts recommend installing a separate differential automatic device for such equipment. This part will protect the device from possible electrical shock if unforeseen circumstances occur.

- Both during assembly and during the operation of a homemade mechanism, it is very important to adhere to safety rules. Take care not only to protect your hands, eyes and feet, but also to ensure that all parts of the shredder are securely fastened.

- When working with a homemade shredder, you must ensure that no inclusions such as stones or glass, metal or plastic get into its receiving hopper. During storage, these elements should also not be in the container. They can seriously damage the structure of the device.

- Twin-shaft plants are most effective in shredding wet branches. If it is necessary to process the elements of dense rhizomes, then they will need to be thoroughly cleaned from contamination.

- If the snare drum is jammed due to wood inclusions stuck in it, then the device will need to be disconnected from the mains immediately. In the future, it is permissible to remove stuck waste only when the device is de-energized. Otherwise, you are putting yourself in serious danger.

- During the operation of a shredder (any - both branded and home-made), it is very important to ensure that the power cable of the device is not in the area of the release of crushed waste.

- If you want your homemade shredder to last as long as possible, then it will need to be thoroughly cleaned after each crushing job on site. After this, the device should not be thrown outdoors. Allocate a shed for it or equip a canopy.

- Make sure that the blades of the device are always well sharpened. Thanks to this care, it will be much easier and more pleasant to use the device, and a large load will not be applied to its main components.

Only by observing all the above features of operation can we talk about the durability and wear resistance of the grinder, which you made with your own hands. Of course, the quality of all the constituent components that you use during manufacture also plays an important role. Treat this equipment with care and attention. Do not forget to constantly clean it so that crushed waste does not accumulate (in advanced cases, it can be quite difficult to remove them). In addition, you should remember about your own protection while working with this technique.

Do not under any circumstances start cleaning or repairing it while it is still plugged in.

How to make a homemade chopper with your own hands, you will learn from the video below.

The comment was sent successfully.