Choosing a stump grinder

Technological progress is rapidly moving forward. Now you do not need to pick up a shovel and spend more than half a day to independently uproot an interfering stump, because a special grinder has been invented for this.

Appointment

A stump grinder or grubber is a mechanism designed to completely remove a stump from the ground with minimal damage to the surrounding soil. For a small land plot where you need to uproot 3-4 stumps, buying a shredder will be an irrational waste of money, because their average cost is around 150 thousand rubles. The grubber can always be rented.

However, in the presence of vast territories, the purchase of this device will be a rather profitable solution.

Classification according to the principle of operation

All lifters can be classified according to several criteria: the shape of the cutter, the way of working, the level of possible deepening into the ground.

Consider the types of cutters installed on the grinder.

-

Disc shredders. They, in turn, are divided into vertical and horizontal forms. The first option is most often used. Vertical milling cutters include a metal disc, the thickness of which usually does not exceed 5 cm. Cutting elements with sharp edges are installed on them. The advantage of disc milling cutters lies in the high speed of wood chipping. However, they can destroy the trunk only to a depth of 20-60 cm, therefore, such cutters are not suitable for delimiting an underground section of a tree. On the other hand, the tips of the cutting elements have a long service life as they do not meet the ground and the edge dulls much more slowly.

- Drum grinders. Drum cutters are differentiated into road and rotary machines (mulchers). The latter are excellent for working with stumps that are deep underground, since the tips of the cutting parts are rounded, which means they do not become blunt under the influence of the soil. Road milling machines are designed to crush hard surfaces such as concrete and asphalt. Mulchers are used to break stones during the preparation of fertile land for planting work. The disadvantage of rotators and road milling machines lies in the dependence of the speed of wood crushing on the pressure applied to the stump.

- Rotary shredders. The principle of operation is simple: the rotor goes deep into the soil, the device passes over the surface and turns into crumbs everything that comes in its way. There are two types of rotary shredders: drilling and cylindrical modifications. The drilling variation consists of a long shaft with a tapered threaded tip (drill), and above it there are cutter blades. By screwing into wood, this drill is used to create additional vertical pressure, which increases the efficiency of the blades breaking the wood. When meeting the surface of the ground, the cutting edge is not damaged due to the low speed of rotation. Consequently, the maximum depth that can be reached depends only on the length of the shaft and the mobility of the drive. The cylindrical version is a shaft (cylinder), at the end of which there is a rounded cutter. The device shows its maximum performance only at a fairly high pressure. Thanks to the cylindrical modification, small stumps can be easily removed. In addition, after the operation of the rotary shredder, the soil becomes loose, since it crumbles not only the stump itself and its roots, but also large stones.

Types by installation method

According to the method of installation, stump grinders can be divided into several types.

Manual

Such mechanisms include in their design a two-wheeled or four-wheeled chassis, a gasoline engine with a rather low power (from 8 to 30 hp), a gearbox, as well as a vertical disc cutter and special controls.

Practicality and high mobility can be noted as the most important advantages for the sake of which people acquire such a design. It allows you to work in hard-to-reach places where a tractor or self-propelled shredder cannot go. But on soft surfaces, work will be very difficult due to the large weight of the device (on average 100 kg).

The chopper wheels will be at least 1-2 cm deep into the ground, which prevents it from moving to the sides.

Self-propelled

These shredders have many differences from manual lifters by the presence of a hydraulic or hydrostatic transmission, which helps to facilitate their delivery from transport to work sites. Because of this, their cost increases markedly. Besides, self-propelled crushers move on the chassis of wheeled or tracked mini-tractors. Such devices have less mobility, but they are much easier to operate, since the height and turn of the cutter are changed by the hydraulic drive, and for this you do not need to use muscle strength.

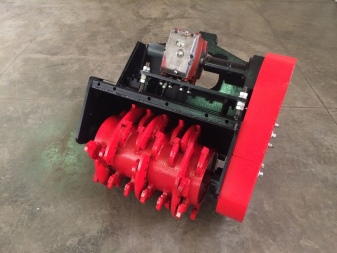

Hinged

Hinged mechanisms are installed on specialized vehicles (or rather, on their manipulators): tractors, loaders, trucks and excavators. There is a possibility of installation on a walk-behind tractor. And also these versatile devices are distinguished by their low cost, since they do not need an individual engine and chassis. The crushing bucket is connected to the transport engine using a hydraulic system or a power take-off shaft.

The disadvantages can be attributed to the inability to use these shredders in places inaccessible to vehicles.

Manufacturers

The first in the list of manufacturers of lifters must be noted Czech company Laski... In the manufacture of models of shredders, the brand uses motors Honda, Lombardini, Hatz, Kohler... Some of their devices have even won international awards. For example, there is a well-known professional model F360SW-GX390T. Basically, it is preferred by organizations that provide landscaping of large areas. The F360SW-GX390T has a powerful motor and a large diameter of stubs to be cut (30 cm).

The equipment of the Russian company Sable is in no way inferior to imported counterparts, and in some cases even surpasses them, providing new opportunities.

Of the advantages of shredders by Sable include a unique disc brake system, a movable frame with a turning radius of 60 degrees in different directions, an ergonomic comfortable handle, special tires with high tread and the ability to process wood of any diameter in depth.

Swedish company Husqvarna also engaged in the production of grubbing machines, and no less successfully. Their designs allow for work in the narrowest aisles with a width of 700 mm, and the introduction of an ergonomic design greatly simplifies the process of operating and transporting equipment.

If we talk about the most popular models, then as an example we can cite tractor shredder XYLOCROK by Rabaud, which is ideal for use on MTZ tractors (especially important in Russia).

The comment was sent successfully.