How to make a do-it-yourself feed cutter?

A feed cutter is an indispensable item in agriculture. This device allows you to quickly cut products for the preparation of feed for livestock, thus providing all the animals with the necessary food in a timely manner and without hassle. The feed cutter is especially useful where the number of livestock is quite large. What's more, science says that minced food is better absorbed in animals, which means it makes them healthier.

Device

Despite the fact that the feed cutter is a rather noisy unit, this option is inexpensive and easy to operate. Such a device has a high efficiency and is always open to improvement.

Every cattle breeder will be able to assemble a feed chopper manually. To do this, you need to have a metal bucket, an old washing machine or a grinder in your arsenal. You also need to purchase a steel pipe with a diameter of about 35 cm. If necessary, the design is supplemented by an electric motor, the capabilities of which will be at least 3000 rpm.

The main advantage of a homemade feed cutter is that it can always be adjusted to suit your specific needs. There are many drawings on the Internet, according to which you can build a device with such functionality from scrap materials.

The performance of the machine and the degree of grinding of the food material depend on the drawing.

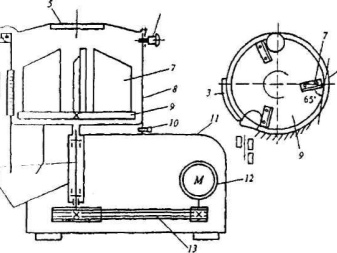

Its basic part is a tank with specially made holes, the main function of which is grinding during rotation. A grinder or an engine from an old washing machine can serve as a torque element. The knives in the feed cutter are set in a cross (to increase productivity) and are attached to an iron disc at the bottom of the apparatus. In general, the feed cutter device has something in common with a juicer without a separator.

A special feed structure is installed on the front side. The material for shredding is loaded into the front cover of the housing, and the back one serves as an access to the knives.

The unit itself is installed on some kind of support, fixed with studs or metal corners. The drum is welded to the corners like the engine itself.

The grinding process is such that first the electric motor is started and the feed material is manually loaded into a dedicated hopper. The knives grind the mass to the required consistency, after which it is fed to the exit.

As a result, the main elements in the device of any feed cutter can be called:

- working chamber with a knife;

- receiving tray;

- motor;

- container for finished feed.

The feed cutter is capable of combining a grain crusher and a grass cutter at the same time, because it processes vegetables, roots, grass, as well as grains and corn

How to make from a washing machine?

It is not difficult to build a food chopper from old household appliances at home. The main thing is to find the right drawing and have everything you need at hand. Then the productivity of the machine can reach 100 kilograms per hour, and crushing food for cooking roughage will become an easy process. A do-it-yourself electric feed cutter is a good budget option that can last for quite some time.

For this you will need:

- washing machine engine;

- her drum;

- profiled pipe for the base;

- thin sheets of steel.

On the base there is a drum with a passage for the motor shaft and a mesh. At least 2 knives are attached to the motor shaft. The drum is secured with four bolts.

The electric motor is installed with bolts; they also connect all the blades. And if there is a need to store food for livestock inside the device, you can attach a lid.

At the bottom of the structure, a large hole is made for the entry of root crops into the device, and the connector for supplying the finished mass is in the wall. A container for collecting feed should be provided at the exit of the cutter. On the side of the frame there is a control with a power cable.

Homemade food chopper from a gas cylinder

It is not difficult to make a drawing of a feed cutter from a gas cylinder, moreover, it is not an obligatory element of the process. The main thing is to accurately make calculations and reliably combine all the components into a single structure.

- First of all, the upper and lower parts are cut off from the gas cylinder. Important! Before that, it is imperative to release gas from it.

- A special passage is cut on the side through which ready food for animals will be supplied. It should be borne in mind that the bottom of the cylinder will be a rotating part with cutting elements.

- The frame is constructed using thick-walled pipes, fittings and corners.

- A cutting element is installed inside the structure.

- At the last stage, the structure from a gas cylinder is mounted on a metal base with a three-phase motor from below.

What else can you make?

A feeder is a device that can be assembled from almost any junk stored in the garage, all at home. It is used in various fields of activity, and it is quite easy to adapt the design to a specific situation. It can be completely different, for example, a manual grater-feed cutter, a mill, a straw chopper. And by replacing the cutting element, you can easily adjust the operating modes of the grinder. Mechanized feed cutters are motor-driven devices that are electrically driven, which ensures high working efficiency.

Important! Only a metal bucket should be used in this kind of construction. The plastic option can be cheaper, but later cost its owners health or even life. If suddenly a shard of a knife ends up in a working feed cutter, the plastic will not serve as a reliable barrier, and the metal can get into a person or animals near the unit.

The angle grinder feeder has a relatively simple device.

- First you need to take any vessel (the main thing is that it is made of thick stainless steel) and make holes 1.5-2 cm in diameter in it. An important nuance is to fold their edges inward for more efficient chopping.

- Next, you need to design a frame, which will later serve as a stand for the container. The container itself is installed on the base using a flange and glands.

- The grinder is connected exactly to the flange, and a case for the stuffing box is installed on top of the axis inside the container.

- An obligatory element here is a container for receiving the crushed material on top of the feed cutter. You can make one from a saucepan or a regular bucket.

A simple and inexpensive option is also to design a feed cutter based on a drilling machine, but homemade products of this kind tend to consume a lot of energy.

Another way to build a productive feed cutter at home is to assemble a structure based on a drill.

- To do this, you need a regular stool with a hole of about 13 mm in diameter. After that, you need to pick up a wooden block with a size of 20x40 mm, and then attach the UPC 201 bearing unit to its smaller end. This whole structure is installed on one side of the stool.

- The next step is to install a galvanized 12-liter bucket with a hole in the bottom on the stool.

- The shaft for the blades must be made from a strong rod, cutting out an M12 thread on one side of it.

- Next, you need to push the shaft through the hole in the bucket and the stool seat by 16 mm and fix it in the bearing. The drawing must be calculated so as to take into account the size of the drill used, and then the structure will be stable.

- After that, a diamond-shaped knife should be made and fixed on the working shaft.

A drill feed cutter usually runs on its own drive at about 1000 watts. Bearing holes and stool must be aligned.

How to make a do-it-yourself feed cutter, see the video below.

The comment was sent successfully.