Everything you need to know about feed cutters

This article outlines everything the average consumer needs to know about feed cutters. It will be possible to deal with household manual feed grinders and electric root crop grinders for animals, with other options for such equipment. It also provides information about components, popular models and how to use it.

Description and purpose

A device such as a feed cutter also has a more official technical name - a roughage chopper. It may seem that the teeth and digestive system of animals can handle any kind of food, but this is not so. Pre-crushing hard feed is very useful in agriculture.

Since it is assimilated easier and faster, it facilitates digestion, accelerates the development of living organisms. Livestock, poultry and domestic animals will be much less sick.

Experienced farmers have also noticed long ago that the animals themselves are more willing to eat just crushed feed. They get more pleasure from this process. The larger the surface area of the piece, the higher the absorption of vitamins and minerals. Another benefit is the ability to mix the chopped mass with added protein and protein, which only increases the effectiveness of the product. But chopping feed by hand is tedious, and with the help of means and devices not intended for this, it is unreliable and even dangerous; that's why you need a special feed cutter.

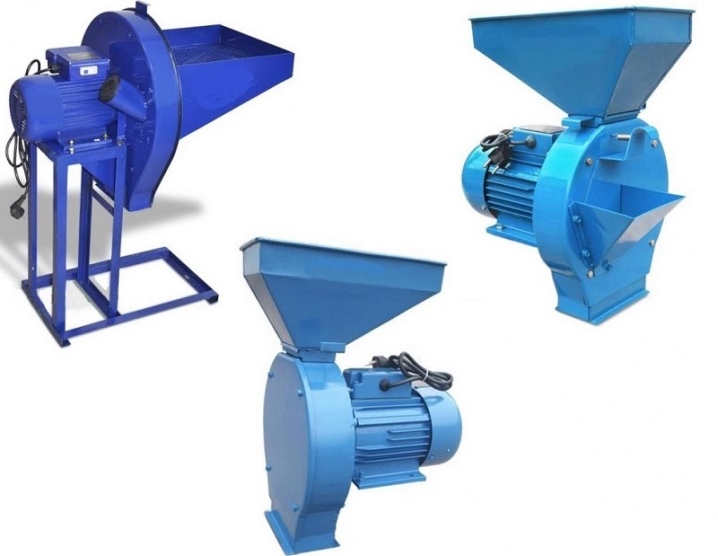

Species overview

The main difference between crushers is how they are built. It is customary to highlight:

-

disk;

-

drum;

-

roller types.

The drum crusher, along with hammers fixed on a special disc, is also equipped with a knife drum. Usually, the drums are supplemented with counter plates in order to cut juicy feed in advance, before the main processing. The roller device has proven itself better for compound feed pellets. For your information: the same devices can also grind grain and grind beer malt.

The basic principle of operation is a run between the rollers; if the teeth of a flat shape are installed, it becomes possible not only to grind, but also to flatten the grains.

Rollers are considered to be a universal type. If all the influencing factors are correctly taken into account, they can be used to prepare food for animals of all types - that is, for livestock, and for chickens, and for poultry of other breeds. Grinding aggregates can have unequal performance. It directly depends on how large the economy is to be serviced. Systems with a capacity of more than 1 ton per hour at home are obviously impractical and cannot pay for themselves.

But the difference isn't just about performance. It is also important what can and cannot be put inside the feed cutter. Common types of forage are green plants and grains. For vegetables, and especially for root crops, it is necessary to use more powerful devices with sharp cutting parts. They are capable of working in 3-in-1 mode.

Household

Disc feeders are powered by a special rotor disc. The drum device uses a chamber with a large number of uniformly dispersed knives. All systems of any kind are equipped with an electric drive. But this is more typical for industrial-grade technology. They can handle the toughest feeds and prepare them on a tight schedule.

Industrial

Feeders of this level will not only provide the necessary products for a large farm. Modern samples of this kind are superior to home-made equipment and outdated models in a number of practical indicators. They are more reliable and safer, more thoroughly thought out. The amount of dust when crushing the grain mass is minimized.

To increase functionality, special attachments are used.

Manual

Such models are mainly used on small farms and households. Yes, they are labor intensive. Yes, there is a lot of waste during work. However, with the help of such a feed cutter, you can supply the necessary food:

-

a couple of cows;

-

several horses;

-

2-3 sheep;

-

5-6 goats;

-

6-10 pigs;

-

10-20 chickens, turkeys.

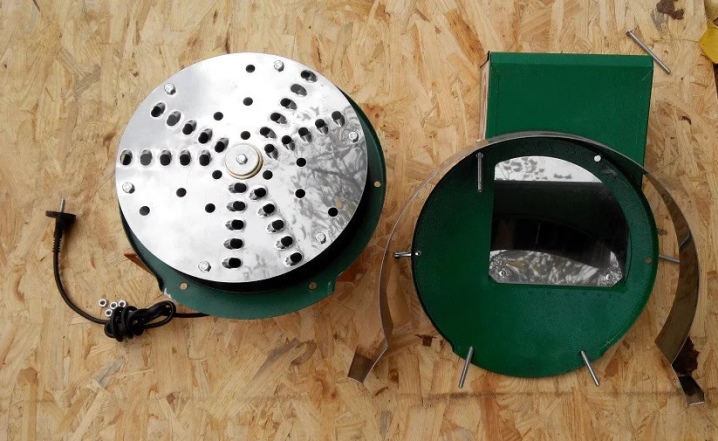

Components

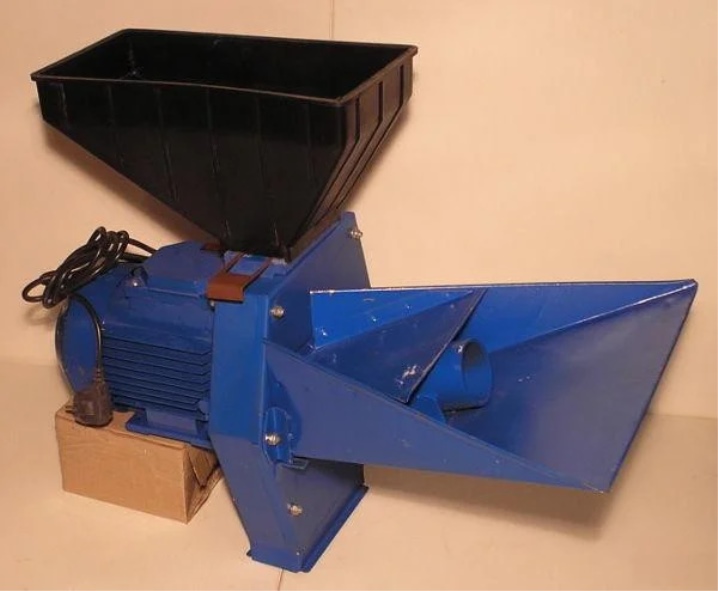

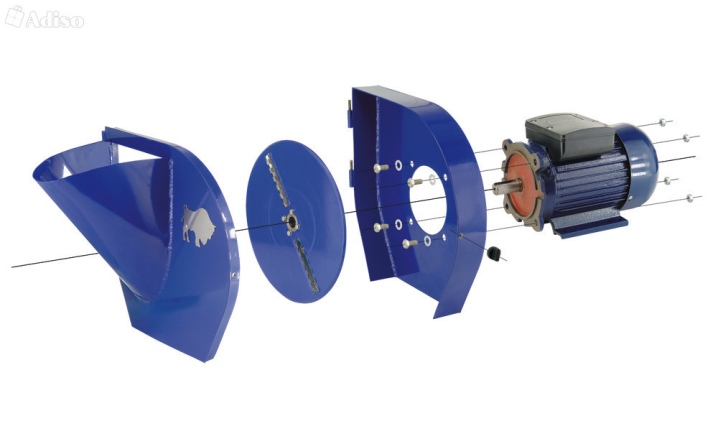

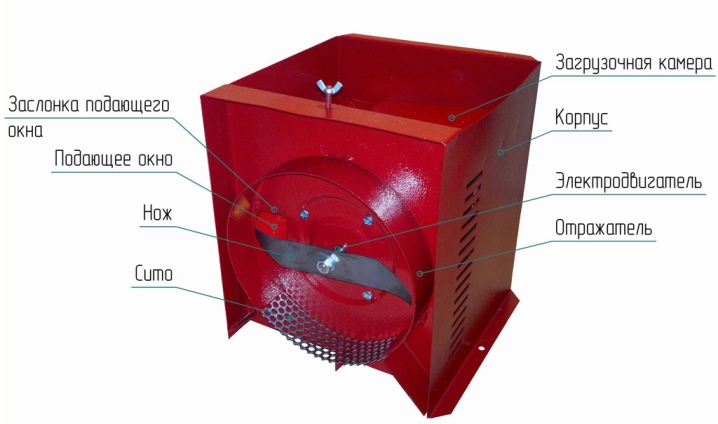

Almost all grain crushers are designed in roughly the same way. The only difference is how many grinding sections are provided. The highest efficiency is characteristic of combined devices in which knives and a drum are combined or, as engineers say, grating and cutting systems. A power case is necessarily provided, which stabilizes the apparatus and excludes the harmful effects of vibration. Additionally, the machine includes:

-

bunker for primary feed supply;

-

transporting block;

-

processing area.

The body hides a pair of cylindrical cameras. The first of the chambers is equipped with a hammer mill. It allows for the initial processing. In the second compartment, a propeller-type knife is usually placed, with a rigid fixation on the cylinder body. To connect the compartments, square channels with a movable mount are often used.

Popular models

There is a great demand for feed cutters "Elikor"... The Elikor-1 model works very simply, thanks to the pressing of several buttons. The receiving hopper has a capacity of up to 5 liters. An electric motor with a power of 1700 W is used for the drive. Knives are mounted on the drive shaft, which are specific for each type of crop. It is also worth noting products of the "Electromash" plant... The IKB-003 model has a very good reputation. Peculiarities:

-

hardened steel knives 0.2 cm;

-

electric power 0.84 kW;

-

mechanical power (taking into account efficiency) 0.75 kW;

-

net weight 8 kg;

-

the greatest time of continuous work 6 hours.

Top rated for agriculture models include KR-03... The device grinds fresh grass and vegetables. The manufacturer claims that it will be possible to prepare mash and mixtures for livestock, animals, poultry. The knives are well sharpened. It is possible to cut the raw material into fragments with a maximum length of 2 mm. It is also worth noting feed cutter "Lan"... Complaints are only caused by active vibration and excessively thin steel. Compactness did not prevent engineers from achieving high power. In 60 minutes, the following are successfully processed:

-

500 kg of root crops;

-

150 kg of field herbs;

-

300 kg of grains.

"IKB-2 Whirlwind" - a feed cutter capable of crushing the plant mass. It emits a relatively quiet sound and hardly vibrates. The possibility of adjusting the size of the produced product is noted. The delivery set includes an auxiliary sieve and grater. The device was equipped with an asynchronous electric motor with a power of 1.1 kW; it provides processing of 600 kg of cereal grains or 180 kg of vegetable mass.

It is also worth taking a closer look at model "IK 1" from the plant "Mogilevliftmash"... The device is suitable for handling all grains and root crops. The productivity for grain is 180 kg per hour, for root crops - 480 kg. The own weight of the cutter is 22 kg. It can be supplemented with:

-

graters;

-

trays;

-

knife for working with stems;

-

fine mesh sieve.

Excellent for roughage "Niva IK 07"... This model is appreciated for its versatility. It will process up to 250 kg of cereals in 60 minutes. Productivity for vegetables and root crops reaches 600 kg. The capacity of the loading hopper is 14 liters, the electric motor is made according to the collector circuit.

The Mlyn-4 system is able to cope with:

-

branches;

-

tough stems;

-

cobs of corn;

-

grain.

Mlyn brand forage grinder:

-

works silently;

-

equipped with a copper-wound motor;

-

serves for a long time;

-

sold with 4 sieves of different cells;

-

processes 65 kg of stalks or 100 kg of corn per hour.

Other models deserve attention:

-

"Utter";

-

"DTZ KR";

-

"Don".

Nuances of choice

The larger the amount of feed loaded, the higher the turnover should be. That is why all devices, except for those intended for a purely personal household, must be equipped with an electric motor. Performance is tailored to your own needs. They also pay attention to factors such as:

-

the size of the model (and the available space on the site);

-

type of feed processed;

-

power consumption;

-

lifetime;

-

the need for repair;

-

maintainability;

-

quality of service;

-

reviews.

Application Tips

There are a few basic subtleties:

-

place the device on a reliable and stable support;

-

monitor the safety of the insulation of the wires and the case;

-

ground all motorized cutters;

-

do not allow strangers and those who do not have the necessary knowledge;

-

eliminate device overload;

-

grind and cut only the feed permitted in the instructions;

-

exclude the processing of wet herbs;

-

systematically replace or sharpen knives.

The comment was sent successfully.