Electric saw repair: fault diagnosis and elimination

In a private household, it is impossible to do without an electric saw, which is often extremely necessary for a variety of works. This tool is compact and powerful enough to successfully cope with various branches, wooden blanks and other similar elements. To repair an electric saw with your own hands, you need to have certain knowledge and skills.

Design features and principle of operation

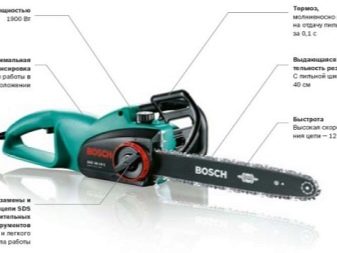

Units such as a chainsaw and an electric saw are made according to the same principle. They differ only in the design of the drive. In an electric saw, the engine is housed in a PVC casing. It also contains: a gearbox, a container for machine oil, a pump, a chain, etc. This design makes it possible to cope with fairly massive timber of various types.

In the operation of the unit, the quality of the sharpening of the teeth, as well as the power of the engine, are of great importance.

The principle of operation of electric saws is simple, but you should know how the tool works.

The nodes that are in the chain saw:

- working saw chain;

- engine;

- reducer;

- drives;

- oil tank;

- wiring;

- frame.

A chain is nothing more than a sequential number of links that are fastened together. The chain itself moves along a special plate (often called a "tire"). The material for the tire is selected very high quality, with a high strength factor. In many ways, the running time of a chainsaw depends on this unit: the better the tire, the better the electric saw.

Tires are of two different types:

- welded;

- solid, which have a tip.

The latter are always made of high strength alloys. In fact, any tire is a "layer cake" of different blocks (at least three), while a driven "sprocket" is inserted into the structure.

A single device in which the tip is present is very convenient to use in a tool of large sizes (where the length of the bus is longer than the standard format). The one-piece design significantly reduces friction (up to 12%). For work, a unit is best suited where there is a tire made of ultra-strong alloys: they can withstand high mechanical loads and significant heating. Also, strong high-quality alloys do not react to interaction with mechanical microparticles and can serve for a long time.

When working with a power saw, it is important to understand that this tool is a source of increased injury hazard. It is possible that a "kickback" may occur, that is, the power saw in this case can suddenly bounce to the side and cause injury. Such incidents occur when too much force is applied to the end of the guide bar, which rests on the work material. To ensure that such cases occur as rarely as possible, companies supply the units with a special brake: it blocks the chain automatically.

The automatic chain brake also has a second name - inertial drive. Its work is due to the presence of a protective element (shield). It covers the left hand of the worker. During the labor process, the shield is placed in such a way that it covers the hand. During operation, if a blow occurs, the hand rests against this element, the mechanism stops.Such a device significantly reduces the possibility of injury from the operating mechanism.

Proper lubrication of the chain itself is very important. As a result of heavy loads during the operation of the unit, an inevitably high temperature occurs and the coefficient of friction of the materials increases significantly.

There is a special container on the saw, into which machine oil is added. During operation, oil is supplied in portions to the working unit (sprocket, chain). In expensive units (from the firms "Makita", "Bosch") there is a special dosimeter of oil supply, which contributes to a more rational consumption of a valuable product and an increase in the productivity of the unit.

There are rules of work that should be followed by both a novice master and a specialist.

- During operation, the throttle valve must be constantly open.

- Sawing at 90 degrees away from you is not recommended. The tool should be held at some angle from the body.

- It is necessary to strictly follow all the recommendations that are mentioned in the instructions for using the electric saw.

- Components can only be used "native".

- Before starting repairs, the tool must be de-energized.

- It is recommended to carry the tool in a cover.

- It is not worth lifting the saw above the shoulder during operation: it is life-threatening.

- In the case of a tool wedge in the material, the saw is removed with the utmost care.

- Fear should be the return impulse, which poses the greatest danger to the worker. When the power saw is switched on, it can cause injury.

- You should be especially careful when working with logs that have uncut knots. The probability of jamming in this case is very high.

- Do not work with an instrument that is not tidied up and adjusted.

- At the beginning of work, a small test run must be carried out.

- An important knot to watch out for is the chain. Loose chain tension will damage the tool and increase the risk of injury.

Possible malfunctions

There are several possible cases of electric chain saw breakage that you should be aware of.

- Poor gearbox, which has a rigid coupling with the anchor of the electric engine. As a result, the entire load goes to the power plant. If the chain becomes dull, then the loads increase, which increases the risk of engine overheating several times. Also, under such conditions, the wear of parts increases sharply. Sharpen the saw regularly and do not apply too much pressure during the manufacturing process.

- Another "weak point" of electric saws is voltage surges in the network, the engine can suffer from them in the first place. If there is no special protection, then with voltage drops, the power plant may simply fail. Too strong protection also negatively affects the performance of the unit - power drops. The golden mean is important here. Good in this regard are products from the domestic manufacturer Interskol: they have found a rational solution to this issue.

If the tool does not function, then it is required first of all to check the presence of current in the network. You should also check:

- the brake mechanism of the chain itself;

- the possibility of breakage of the inertial blade;

- clutch and chain tensioner.

Usually, adjusting the flap allows you to eliminate the defect in a short time. The cable is also checked: damage to it leads to the fact that the unit does not work.

The saw power is significantly reduced if the carbon shields are worn out. The chain can work in jerks: it stops, then it starts to function again. If the circuit serves for a long time, then the risk of such a malfunction will increase. First of all, under such circumstances, the brake band changes, which has worn out over a period of long operation.

In the event of any malfunction, the saw produces a sharp, strange sound. It occurs due to the lack of lubricants, the ingress of mechanical microparticles into the working unit. In this case, you should disassemble the tool, thoroughly clean all working elements.

Often, the engine of the unit heats up too much, the reasons may be as follows:

- poor air exchange, clogged air ducts;

- malfunction of the carburetor;

- the engine "rests" a little during operation;

- defective gearbox;

- old grease;

- the winding is short.

If the saw makes a "curved" cut, then this confirms, first of all, that the teeth are dull.

It is also possible that the tire is about to fail. If the chain does not work, then this indicates a defect in the clutch itself or sprocket.

It should be borne in mind: it is better not to install parts of the Chinese "registration" in the tool, produced by the world's leading manufacturers. Sooner or later, the device will break down, and it is unlikely that there will be an opportunity to restore it. If the case is badly damaged, it is better to give the power saw to the service, because this breakdown is very serious.

Measures such as sharpening the saw are also very important. This should be done regularly to keep the engine under minimum stress. If we neglect regular sharpening and do it rarely, then the saw blade will inevitably be drawn in, it will be exposed to too much stress and, in the end, will become unusable ahead of time. You can sharpen yourself, but it is best to take the saw to a service center. They do this work on special equipment. This is done as follows:

- the chain is removed from the bar and mounted on the guide assembly of the equipment;

- the chain is tensioned using a ratchet that fixes its cutting tooth;

- there is a device on the unit that allows you to determine the correct angle (protractor);

- with the help of an abrasive device, a small layer is removed, which is the final goal of all work;

- after processing the first tooth, work on the second tooth follows, and so on.

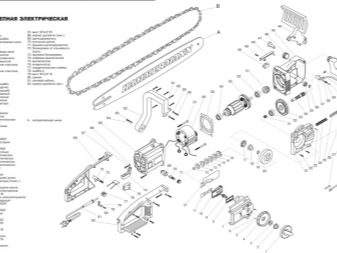

Disassembly rules

Disassembling electric saws is an important phase in the repair of this unit, which must be carried out strictly according to the rules. As an example, the disassembly of a tool from the domestic company "Interskol" will be considered.

- The flag is detached from the screw, it holds the tire, so the fastening should be slightly weaker.

- The saw chain is then also loosened with a device that adjusts the voltage.

- Then the cover is removed, the bolts are unscrewed.

- The chain is removed, the bus is removed from the working unit.

- The "lid" of the working container is removed, where the oil is poured.

- After all the screws are disconnected, the engine gearbox is removed.

- The main asterisk is then removed. To do this, it is necessary to remove the main washer that locks the assembly.

- The screws are unscrewed, the gear clamps are dismantled, then the handle is disconnected.

- The cover is then removed.

- The container with oil is taken out.

- Next, the brake lever is disassembled, which should be pressed slightly until a slight click is heard.

- The gearbox turns over and is disconnected from the shaft and from the housing.

- Typically, a significant amount of dirt and dust accumulates under the housing cover. All this substance should be removed by wiping the nodes with a cotton cloth soaked in alcohol.

- Then the pump is removed from the gearbox, which is responsible for the oil supply.

- The fixing mechanism responsible for stopping the engine is being disassembled. The fixing spring is removed, the rods are removed. You should also remove the brake band.

- Fresh grease is applied to the working units.

- At the end, the brushes are disassembled. To do this, you need to unscrew a few screws.

- The rotor is removed - the last element.

The assembly of the mechanism is carried out in the reverse order. All disassembly phases are best filmed and recorded.

Repair scheme

You can repair the saw with your own hands. This is pretty easy to do. This requires the following set of tools:

- several small files of different sizes;

- a hook that cleans chips from the slots;

- files are flat.

The chain is best sharpened on the tool bar itself. Editing is done along the edge of the cutting tooth, while taking into account the sharpening angle (from 30 degrees). This operation must be done delicately: if the angle is set incorrectly, this will affect the quality of the work and the productivity of the tool.

The file is placed perpendicularly during operation (90 degrees in relation to the tire). The whole process takes place in one vector, translational vibrations are performed, you cannot make any rotational movements. After processing the tooth, the chain moves, then another element is ground. After processing all the elements, the “polishing” of the fixing cut begins. In the case when the cut clamps protrude too much, the chain will not "reach" the material - the working process will not occur. And vice versa: if the latches are excessively deepened, then the saw will get stuck in the tree. The stop is straightened using a gauge that is applied to the edge of the cutting teeth. It is important that the bar is flush with the retainer.

If the limiter protrudes too far outward, then it is trimmed with a flat file. In this case, movements are made in one direction at an angle of 90 degrees.

Security measures

Before starting to work with an electric saw, you should make sure that there are no foreign solid objects: the presence of hard elements can damage the tool. It is necessary to reclaim a defect on the ground, the particles of which can clog the grooves through which the oil enters the working units. Lack of regular lubrication will kill the tool in a very short time. The wedge of the tool should be carefully monitored: overheating of the metal leads to a loss of performance characteristics, which means that the service life of the tool is sharply reduced. It is very simple to determine that the saw needs sharpening: if the shavings "come out" are too small and there is a bloom of a dark color on it, then this indicates that the saw is "dull".

The explanation for this phenomenon is simple: the saw cannot cut the material and crumbles it, so small fragments appear. There should be no radii on the saw head, that is, fragments with torn out areas. The shape of the teeth and the working cutting edge must be unchanged.

Before starting repair work, it is important to make a preventive inspection and correct diagnosis of the tool. The complexity of the repair directly depends on the severity of the breakdown. It often happens that it is impossible to "resolve the issue" on your own. There are breakdowns where special equipment is required. In such circumstances, the tool must be handed over to a specialized service center that has the appropriate approvals and certificates for the repair of such equipment.

In the next video, you are waiting for the repair of the electric chain saw gearbox.

The comment was sent successfully.