Features of Makita electric saws

Makita is a Japanese company with a century of experience in the manufacture of professional tools for repair and construction work. The Makita brand produces drills, hammer drills, screw and wrenches, chain saws and laser equipment. The equipment runs on electricity, gasoline and a battery. There are more than 350 types of tools and over 4.5 thousand accessories for them.

Brand features

Products of "Makita Corporation" are represented by thousands of names of all kinds of construction and repair devices. Each of them has a wide range of models that have a well-deserved demand from consumers around the world.

The produced equipment of the Japanese brand Makita is distinguished by impeccable quality, functionality, performance and convenience. Japanese specialists established this production in Germany and China, and then opened factories around the world.

Makita devices are distinguished by their high power and excellent performance. They are productive and highly efficient.

The most popular is the Makita-branded electric chain saw. It is appreciated for its reliability, affordable cost and high quality performance. The saw is designed in such a way that it is convenient to change parts on it yourself, without contacting a service center. And all the accessories for working with this tool are always available for free sale.

Characteristics and device

Electric chain saws are a good replacement for gasoline powered devices. They are distinguished by quieter operation, no harmful emissions and easy operation; low temperatures, which paralyze the operation of gasoline analogues, do not affect the efficiency of electric saws.

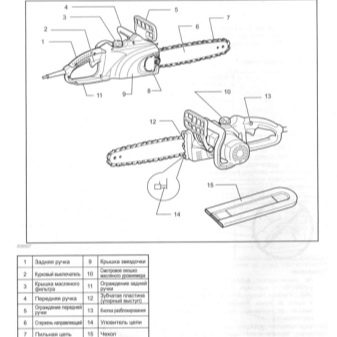

Under the body of the electric saw is a powerful motor. Through a gearbox, it is attached to the bar on which the chain is stretched. The motor can be located longitudinally along the body or transversely to it. The body also has buttons for starting and locking. There is also a screw that secures and regulates the chain tension.

The saw is equipped with a protective shield in front of the front handle. It also serves as a hand brake for the chain - if it is blocked or broken, it will prevent damage to the hand holding the tool.

Another important component in the design of the device is an oil tank with a pump.lubricating all rubbing parts. The lubrication system prevents premature wear of the saw components. But over time, replacement may require a gear and an anchor - the working components of the tool.

Advantages and disadvantages

The Makita company does not descend from the leading positions, primarily due to its high-quality products. The electric saws of this brand have a number of significant features that are highly appreciated by both professionals and amateurs:

- small weight and dimensions;

- stability of traction characteristics;

- operation at subzero temperatures;

- reduced noise level with minimal vibration;

- ergonomic handle design;

- easy maintenance;

- affordable repair.

Of the minuses, judging by the reviews, it is worth noting:

- some models use a lot of oil;

- oil leaks when inoperative;

- the network cable is not long enough.

But all these disadvantages are easily solved by using an extension cord, wiping the body from oily traces and using oil waste in order to save money.

What are they?

When working with a metal or wooden surface, it is often necessary to cut evenly at a certain degree. An ordinary grinder without some experience and skill will not cope with this task. For such purposes, it is better to use a metal cutting pendulum saw.

This power tool consists of a motor, a cutting blade, a frame with a vise-clamp of the workpiece to be sawn, a swivel joint (for adjusting the blade) and a protective cover.

In the manufacture of any metal structures, workpieces of a certain size must be cut. For example, steel corners, profile pipes, etc. The grinder is also masterful in this work, but it will not work for a perfectly perpendicular cut (especially if there are several dozen such cuts). In this case, the chainsaw will be an indispensable tool.

The cutting saw (pendulum) is a mobile machine with small dimensions to facilitate cutting a metal workpiece at an arbitrary angle. This is a popular type of tool, often used in construction and for repair manipulations. Differs in mobility and simplified device. The pendulum mechanism makes cuts exclusively at right angles, without the possibility of changing the degree. For comfortable work, a belt drive is used in the design of such tools, which allows you to operate smoothly and without jerking.

A pendulum saw with an electric motor for metalworking has no practical differences from an identical woodworking tool. The only difference is the type of circle used.

With regard to the transverse and longitudinal arrangement of the engine, there are many different opinions and facts. But in the work, both types of electric saws demonstrate efficiency. However, some nuances must be taken into account when choosing. First of all, you need to focus on the purpose for which you have to use the saw. You will need a diamond saw to cut the tiles. For cutting tree branches and bushes, especially when sitting in a tree, a compact narrow gasoline saw with a longitudinal motor is more suitable. It is manoeuvrable and designed to work at any angle and in any plane. It is a perfectly balanced tool that does not “tilt” to the side during operation. But it sometimes gets wedged when starting with a slight jerk to the side.

It is worth looking for a tool with a soft start system.

For sawing logs, it is best to use a transversely motorized saw. Any combination model will do. It is not so compact, but it is much more powerful, more reliable and cheaper than a similar tool with a motor located longitudinally. Productive tool performance with minimal back stress due to its light weight is a clear advantage for free cutting of massive logs. Despite the shifted balance, these types of saws have the best speed and productivity.

Model rating

The Japanese brand allows you to choose the best and most suitable, including among a wide range of electric chain saws. They are subdivided into professional and household tools. Below is a short list of well-reviewed models. They have the most intuitive design and operation, which makes them the most suitable for private applications.

UC4051AX1

Romanian assembly model. Intended for household use.

Distinctive features:

- Electric drive - 2 kW;

- forty-inch cutting unit;

- weight - 5.6 kilograms;

- comfortable handle;

- oil pump with an increased resource, which automates the process of lubrication of the system;

- longitudinally positioned engine and perfect balancing;

- safe work in humid environmental conditions due to the reinforced insulation of conductive assemblies.

The device perfectly copes with cutting down tree trunks, sawing firewood, in the construction of various structures made of wood.

UC4042A

Power tool with a capacity of 1.8 kW with a forty-inch tire and weighing 4.5 kg.

Is different:

- convenience of self-tensioning of the chain;

- comfortable handle;

- high build quality.

The links with a large pitch allow you to use the saw in the construction industry or for domestic purposes. Due to its low weight, the electric saw is convenient to use when working at heights. In the reviews, users complain only about a minor minus of the tool - a generous consumption of lubricant.

UC4030A

Electric saw with a power of 2 kW, weighing 4.4 kg and with a forty-inch bar length. Collected in Romania. High-quality sawing is ensured by the large chain pitch. The owners' reviews note the quality of the saw's cutting on wood and the process of work itself.

This is due to several parameters:

- high power with modest dimensions;

- auto shutdown when the chain suddenly bites;

- strong knots that can withstand metal;

- a high-speed brake that stops the chain in a couple of seconds;

- decrease in power in case of instability of the mains voltage.

So that the oil is not consumed excessively, you need to choose the right consistency. A grease that is too liquid in consistency has a faster consumption, and with an excessively thick one, difficulties arise during operation.

UC4020A

Model with standard power of 1.8 kW, weight - 4.4 kg, typical width 40 inches. With such a tool, it is easy to process large quantities of wood (even logs with a cross section of 40 cm).

Is different:

- low weight;

- high performance;

- economical oil consumption;

- convenient chain tension.

There are laudatory reviews about this model of the electric saw. The design and characteristics do not give rise to criticism of the tool for the quality and efficiency of work.

Optional accessories

All the necessary components are on sale to ensure the high performance of Makita electric saws. The manufacturer made sure that you can additionally purchase protective covers for tools, tank covers, clutch cups, plastic wedges, guide bars, chains for bars from 16 to 74 cm and files for high-quality sharpening of chains.

To ensure smooth running and high-quality cutting, special lubricants for the gearbox, silicone pastes, and engine oil are offered. With assembly tools and fuel and oil containers, chain saw kits, depth gauge, radial rings and guides, spark plugs and filters, maintenance and operation is easy.

User manual

To use the electric saw to be safe, you need to follow the recommendations from the instructions attached to the device. Operating rules are usually not complex requirements and precautions.

- Use the saw intermittently. If the tool is heating up, then it is time to pause to avoid overheating and damage.

- The tool must be chosen consciously, depending on the purpose for which it is purchased. Do not use the saw for other purposes. For example, models with weak parameters are not intended for cutting forest plantations.

- The chain is also selected for specific jobs. Fast cutting is facilitated by a large link pitch, but at the same time, oil consumption and energy costs increase. A smaller step of the links slows down the process, but makes it more economical.

Choose a wide-pitch chain for sawing wet, medium-density wood, or use a small link for dry firewood and cutting branches.

- If the model is not protected from moisture, it is not recommended to operate it during precipitation and foggy weather.

- Before starting work, you need to make sure of the integrity of the belt, the quality of the chain tension and the brake response.

- You need to work with the saw in a stable position, holding the tool with both hands.

- Not all models automatically lock the circuit after pressing the shutdown button. The wood saw must be removed from the wood after it has come to a complete stop.

- It is not recommended to use the saw above the shoulder level while it is in operation.

- For safety reasons, it is strictly forbidden to turn on the device if the cord is damaged.

- In the process of work, it is necessary to control the location of the cord, not allowing it to intersect with the working blade.

- It is important to use good quality wiring. Modern high-power appliances can ignite old wiring.

- You need to change the oil in time, change the worn out parts.

- Correct installation of spare parts in place is also important. Replacement can be done by yourself. It is also easy to pour oil into the tank for lubrication, tension or remove the chain.

Instrument care

The electric saw requires some care, like any electrical appliance. After completion of work and before long-term storage, the device must be cleaned of sawdust, drain the remaining oil, remove the chain for subsequent sharpening and the tire for easy cleaning of the interior from dust and dirt.

With frequent use, all working elements must be periodically checked for possible wear and damage, the bearing and sprockets should be lubricated from time to time.

The condition of the carbon brushes should be checked periodically. This is necessary to maintain maximum traction in the saw circuitry. Each brush has a special notch to mark the abrasion limit.

It is important to take into account the fragility of the carbon brushes so that they are not damaged during inspection or replacement.

Possible malfunctions

All breakdowns of Makita tools can be roughly divided into two types: those requiring repair under warranty and those not covered by the warranty. In addition, tool breakdowns occur in terms of mechanics and electrical engineering.

Faults in which warranty service is possible:

- Breakage of the rotor due to a short circuit between the turns in the winding (with no signs of improper handling of the tool and stator integrity).

- The place under the impeller is weakened (with the exclusion of interference in the form of trapped foreign objects).

- Malfunction due to breakage of the rotor due to destruction of the bearing and confirmation of the absence of facts of incorrect use of the tool.

- Breakage of the rotor with the destruction of the collector (loss, deformation of the lamellas) - subject to the detection of an interturn short circuit in the winding and the integrity of the insulation.

- Some winding does not work in case of breakdown on the case or in insulation between the turns, breakage of the winding itself without mechanical damage.

- Damage to contacts - when establishing the fact that the rotor is intact, and the saw was not overloaded and the conditions of its operation were not violated.

- Breakage of the switch. The tool cannot be adjusted according to the number of revolutions (if the connection cord is not damaged). There is no damage to the switch and there is no heavy contamination on the housing.

- Inoperative unit in the absence of visible damage on it and on the cable, cracks on the case.

- The speed has ceased to be regulated, the saw does not start, or an unstable operation is noted.

- The brush holder does not work in the absence of mechanical damage and dirt on its body or on the power cable.

- There are no external signs of mechanical damage, as well as fracture, kinking and stretching of the power cord, but it does not work.

- There is a problem with the heating element with a broken coil.

Problems for which repair is not guaranteed:

- complete wear of the rotor collector from prolonged operation of the tool or the use of non-original carbon brushes;

- malfunction of the rotor and stator due to heavy pollution, poor ventilation or overload;

- breakdown of the switch of a mechanical nature or due to the accumulation of processing residues and construction dust on its case;

- failure of the function of regulating the number of revolutions due to pollution, dustiness, improper handling of the device;

- deterioration of the power cable due to the use of an extension cord with a damaged outlet or an outlet that does not fit the plug, which caused it to be melted;

- destruction of the heating coil from overheating of the tool, mechanical shock or violation of the conditions for correct handling of the saw;

- breaker damage due to untimely stop or breakage of the heating element spiral.

It also happens that the lubricating oil is not supplied to the tank by the pump, as a result of which the parts are not lubricated or oil is not supplied to the chain.

These breakdowns also have reasons that need to be sorted out. Then you can understand whether the repair under warranty is compensated by the service center or you will have to deal with the problem yourself.

Another possible malfunction is that the chain cranks under load. It is necessary to check the strength of its tension, the probability of jamming and the condition of the sprocket. It is quite possible to carry out minor repairs of the instrument on your own.

Electric chain saws from this manufacturer are a tool that fully justifies its price tag. Simple maintenance, usability and quality assembly set the brand apart from an impressive number of competitors. With all the obvious advantages and a large assortment, it allows you to make the best choice for household needs, without overpaying for unnecessary characteristics and the name of the promoted brand.

For more information on Makita power saws, see the following video.

The comment was sent successfully.