Bulgarian: where did this name come from?

Usually we get very used to the names of things that surround us, and do not particularly ask ourselves the question of the origin of the name. But still, for sure, many craftsmen would be interested to know why the Bulgarian is popularly called that.

Historical facts

It turns out that everything is simple here. Most of the things in our native language received a name in connection with the state, region, region they came from. This useful device is supplied to our state from Bulgaria. What is interesting here is the fact that apart from Russia and the states of the former USSR, nowhere else has equipment acquired a similar terminology. Its patented term is used all over the world - an angle grinder. The equipment was supplied to the Soviet Union back in the 70s of the last century. Local craftsmen christened it "Bulgarian" according to the name of the state of the manufacturer.

The grinder was manufactured by the Sparky Eltos company, which functions to this day. And you can easily find Sparky products on the market space of similar products. But today this company has lost its relevance, since in the market conditions its products are semi-professional, and the price is the same as professional equipment of popular world brands. At the same time, "Sparky" has its customers who like and are used to the equipment of only this brand.

There is a second explanation for this name. In the 70s, there was a peak in the shortage of various goods in the USSR. The shops delighted customers only with the equipment of the Bulgarian "Sparka". Since there were no other suppliers, the tool was called a grinder. Based on the facts of those years, one can find another factor that influenced the origin of such a name for the instrument. A large number of Bulgarians worked on construction sites in the USSR, and most of them had their own tools. Hence the name Bulgarian. And now this equipment of our and foreign production is called the same.

Another name for this device is fortune. One of the first grinding machines to appear in the Soviet Union had this name. It quickly gained popularity as it was very convenient and fulfilled many functions. The next name is the impeller. During operation, the grinders made harsh sounds, they resembled the sounds of an aircraft turbine, and although this name is not very common, it can still be heard today.

Another name is flexi. But in our country it is not used, but in Europe everyone will understand what kind of instrument they mean. At the beginning of the last century, the MS-6-flexen device appeared in Germany, so the name flexi stuck. Years go by, there is no such model of the car, but the name remains. There is another name for the tool, it is little known, but it is still used. This colloquial name is monkey.

Official name

The correct name of the tool is an angle grinder. It is difficult to perceive, but the word Bulgarian is better remembered. This device is called an angle grinder due to the fact that it has many different grinding attachments. This tool is used in most cases when you need to cut off some material, forgetting about the other positive properties.In most cases, a stone or metal cut-off wheel is used than other grinding attachments. And angular because the device where the attachments are located is located at an angle to the frame.

Grinder properties

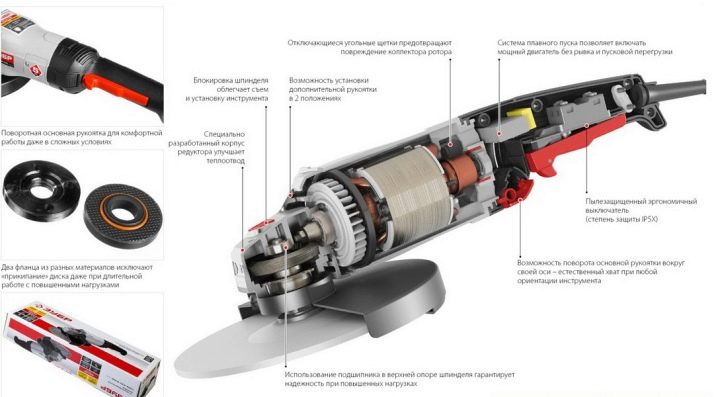

The device is a power tool, which is a subspecies of a grinding machine. It is mainly used for abrasive processing. This includes grinding, cutting, cleaning products made of metal, stone and other composition. The tool has found wide application in wood and metalworking, construction. The body of the device is in the form of a cylinder. Sometimes there is a handle on the side. The structure of the elements is as follows.

- Multifunctional brushed motor.

- Angle transmission.

- On and off lever.

- A device for fixing a circle.

- A mechanism that regulates the speed of the disk. Available on some devices.

- The attachments are special abrasive discs and brushes.

The complete set of the machine can be divided into two parts: electrical and mechanical. The heart of the sander's electrical part is an AC electric motor. The rotor contains several sections with windings, whose leads are located on the rotor armature plate. Low cost and power machines have a constant rotation speed. Powerful models have a special regulator, which is located on the handle, with its help you can change the engine speed.

There are bearings at both ends of the rotor shaft, they are fixed in the frame. This allows for the smooth operation of the shaft during operation. The revolutions of the electric motor are transferred to a gearbox, which can change the direction of the revolutions and transmits the rotation to the cut-off wheel. The reducer includes two helical gears. The small one is located on the motor shaft, and the large one is on the gearbox axis. A circle is attached to the segment of the axis located outside.

If the model is professional, then it can be additionally equipped with a splitting clutch, which turns off the revolutions of the working circle of the device in the event that it gets jammed during material processing. If such a clutch is not available, then there is a possibility that the circle will break, scattering to the sides. Part of the circle is covered with protection to protect open areas of the human body from small particles of material and dust.

The circle for work is attached on the outer segment of the axis with a nut with a special key. The immobility of the axis section is achieved by using a lever on the frame of the device. There are longitudinal slots on the plastic surface of the tool. They must be kept open while working because they are used to cool the engine.

Types of grinders

In industry, the use of a grinder is associated with its class. The following types are distinguished.

Economy class

A relatively cheap tool, with an incomplete set of parts and accessories. Some of these models are unreliable and dangerous to use. This tool is rarely used for small businesses. The grinder frame is designed for light loads only. The mount is strong, however, it does not guarantee comfortable operation. For household work, it goes well, but the engine is not protected from dust, during operation, the smallest particles will get inside and this will increase the wear rate of rotating parts. The tool will need to be repaired. When metal particles get inside, they can cause voltage surges. In order to make repairs, for serious construction work, you need a more powerful grinder and of a higher quality.

Middle class

Equipment of this type is very comfortable and reliable to use. It has dense inserts, and the motor is covered with paint, which serves as a protection against dust penetration into the case. The angle grinder is used for household work, it has a clamping mechanism, which makes it possible to quickly align the position of the protective cover.The device has comfortable engaging levers that can be operated without even removing rubber gloves. It is possible to attach the handle to the right and left, and this makes it possible to use the product for both right-handers and left-handers. In some models, the handle is located at the top, which makes the product more comfortable to use.

Professional class

Products of this class rarely require repair. The electric motor and rotating parts are protected from dust penetration, and the grinder itself has a property that ensures a smooth start. This makes it possible to gradually increase the speed of rotation and operation of the disk. It is possible to connect the product to a lower power grid.

Factors for product selection

Choosing a grinder, it is worth concentrating on some of the signs:

- scope of use;

- the size of the handles;

- the component parts of the tool must be rubber;

- the massiveness of the working circle.

Angle grinders have different body sizes and wheels. The large diameter is 2.5 centimeters. Such a circle cuts material from bricks, slabs, pipes, etc. The most acceptable circle size for activities at home will be 1.3 cm. When carrying out repairs, you need to take 1.8 cm. Power can be in the range from half to 2.5 kW.

Its choice depends on the period of operation and exposure of the motor. Sufficient motor power is required for the disc to rotate. Of the additional features, a smooth start should be noted. The system starts the engine without harshness, correcting the mains voltage. Disk auto-balancing is considered an important feature. It is needed when the discs work unevenly; here, vibration is corrected and reduced.

Precautionary measures

It is necessary to work with a grinder in gloves, and cover your face with a mask. Never remove the protective cover when using large diameter wheels. It is best to use a dust mask, especially when working with stone material. Clothing should not be too loose to avoid being caught in the rotating circle. Before starting work, you need to inspect the device for damage. The grinder is not intended for woodworking.

For information on how to use the grinder correctly, see the next video.

The comment was sent successfully.