Everything you need to know about clamps

Everything that an ordinary consumer needs to know about clamps can be found in this article. There is basic information about screw and clamping, about plastic, reinforcing quick-release and other types. A very important role is played by a clear understanding of the clamps X1, X7, X51 and other sizes on the market.

What it is?

It is very useful to start the story about clamps by reflecting their essence. Many people understand it in a simplified way, simply as a "way to fix something." Such devices appeared about half a century ago - and immediately replaced traditional welding joints. They turned out to be much more practical and more convenient, installation takes much less time than when manipulating welding machines. In relation to clamps, GOST 24137-80 applies, which refers to parts connecting pipelinesas well as GOST 28191-89, describing clamping devices for sleeves; both standards regulate dimensions and design features.

Applications

Clamps can be used in a wide variety of applications. A fairly common option is special ties for wires and cables of various types. It is very easy to buy such products - they are sold in any large supermarket of electronics or household goods. But clamps are also used:

-

for a sewer pipe (it can be metal or plastic);

-

when laying gas pipelines;

-

when creating water pipelines and heating networks;

-

when organizing technological communications;

-

for grounding the metal hose (usually with a clamping screw).

Species overview

Historically, the very first clamps were for horses, and cavalrymen and cabbies, farmers and coachmen, professional riders could not do without them. Today it is almost impossible to see such a product. But instead, a large number of other types of clamps appeared. As before, their main function is to securely fix various objects. It's time to get to know some of them.

By design

It is customary to call ear-mounted non-separable stepless fasteners. Such products connect hoses through which water or air flows. The size cannot be changed arbitrarily. All such mounting elements are disposable, and special pliers help to fix them in place. It is also worth considering the possibilities of spring clamps.

This design is recommended for elastic connections of water supply and heating networks, for fastening individual pipes of such a profile. It can also be seen in cars, ventilation and air conditioning systems. The variable clamp is used:

-

in the plumbing industry;

-

for thick-walled sleeves;

-

for large hoses;

-

for industrial needs.

By type of attachment

Everything is very simple and predictable here. A large part of the clamps are designed for rigid fixation. The connected product (pipe or something else) will be completely motionless. The crimp brackets are bolted tightly. Such devices are needed at bends and on branching sections of pipelines.

There are also flexible mounting clamps. They are mainly used in heating systems and hot water supply circuits. Flexible resizing allows you to compensate for movements and stresses caused by thermal expansion. Importantly, this design has almost no effect on the overall reliability of products.Hydraulic lines, on the other hand, will last much longer under any normal conditions.

But, in addition to the classification by the type of fastening and design, there is another important gradation - by the type of purpose. And here it is immediately worth mentioning about the seatpost models. Contrary to the obvious, they are used not by riders, but by cyclists. Regardless of the specific brand of bike, the device is generally pretty close. Only occasionally do manufacturers introduce original innovations into their products.

But sometimes, along with universal designs, options are used that are optimized for frames with enhanced aerodynamic characteristics. You can also find fasteners made of carbon (as lightweight as possible) and products for additional installation of trunks and trunks. As for the quick-release clamps, they are mostly designed to work with ventilation communications. The main structural element is most often steel.

The reinforcing type is intended primarily for high-load sewerage networks. With the help of such clamps, you can reliably insure against an increase in pressure in the system. The transferred pressure is determined by the diameter of the product. The screw version is designed to fasten the hoses to the fittings. Sometimes it is also used to repair pipes without using a welding machine; an important feature is the double-sided clamp, which is more even than the force applied on one side.

Most often, models with a rubber seal are used, the task of which is to prevent damage to the processed pipe, hose and other objects. All parts made of metal are zinc plated to protect against corrosion. For the grounding of pipelines, a clamp is preferable. In some cases, he is taken to fix communications.

And even such a wide variety of modifications does not exhaust the entire possible range. So, clamps are often used to collect scaffolding. They are divided into:

-

turning;

-

non-rotatable;

-

docking;

-

special subtypes.

If it becomes necessary to lay wires and cables, then there are simply no special alternatives to Velcro. All such modifications are supplied with soft buckles. With the help of these reusable devices, it will be easy to assemble cables into bundles or attach them to brackets, organizers. The deployment of cable communication lines is greatly simplified. If you need to attach the pipe to a wall or floor, a nut design is much preferable.

It is also used when installing pipelines on ceilings. To connect to a pressurized pipeline, it is often recommended to use a mortise-type clamp. It is highly reliable even under heavy load. Some models have a flanged outlet. The outer section of the pipe he serves can be 10-122.4 cm, and the working pressure sometimes reaches 16 bar.

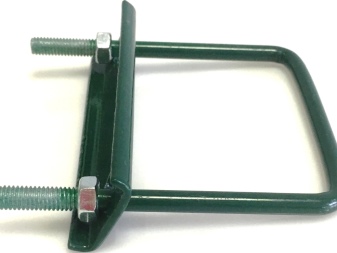

Special attention should be paid to U-shaped clamps, which are sometimes also called bolts-brackets. Such products usually have threads from M6 to M10 and are used in assembly and rigging works. Beams, square or rectangular pipes are suspended from them. Fixation is done with nuts and washers. In many cases, quick-release connecting clamps are also used.

They are completely safe and help out where long-term reliability of the created connections is critical. We are talking about filtering or filling systems for technical communications, first of all. Since the connection is easy to disassemble, there are no problems with cleaning, which is very often required in the same food industry. It is also worth paying attention to the marking version of the clamp. More precisely, the marking function is performed by various types of tags attached to such structures. Many companies supply products with a marking platform.

It is useful to conclude by pointing out two more key types of such elements. Snap clamps sometimes have a double locking head and are secured by a gear mechanism inside. Products for attaching pipes to horizontal and vertical surfaces are often supplied with a stud. Many leading manufacturers make such products with the expectation of intense ultraviolet irradiation.

Materials (edit)

The plastic clamp is used where flexibility is needed, and the loads are at an average level. Direct sunlight is harmful to this material. The thermal range is from -10 to + 60 degrees. But near critical temperature points, reliability is not guaranteed. Stainless steel structures are strong, relatively ductile and can withstand significant stress.

The exact parameters are determined by the type of metal, its thickness and the format of the lock. Since even the best steel can corrode, the use of galvanized materials is recommended. As for copper clamps, these are usually power single-bolt models. Strictly speaking, the main structural material is steel anyway, and copper is present only in the surface layer.

Products with a rubber gasket are used wherever a stable and reliable fastening system is needed that does not damage the attached materials and structures.

Dimensions (edit)

The size grid is approximately as follows:

-

X1 - 230x240x75;

-

X7 - 230x245x70;

-

X8 - 230x285x80;

-

X42 - 215x240x75;

-

X10 - 190x220x75;

-

X51 - customized.

Nuances of choice

Of course, in any case, a stainless steel clamp is more attractive than a ferrous metal clamp. However, this consideration cannot be limited. Cotter pins are considered obsolete and can severely damage the connected products. Screw structures do not allow for a particularly accurate, full-fledged tie. The worm version is even stronger, and the most stable designs are without through serifs.

Required tools

For work you will need:

-

construction tape;

-

household drill;

-

pencil (marker is better);

-

screwdriver;

-

hammer.

When working with cars, the pliers for removing the spring or band clamps are very important. They allow you to work, for example, with the pipes of cooling systems. Clamping pliers are often used by professionals as a clamping tool. Such structures must have a minimum compressive force (allowing one-handed operation), and compatibility with all sizes of fasteners is also indispensable.

As for the device for tightening wire clamps, it is usually not bought separately, but is made with your own hands from shaped pipes in combination with a steel bar or hairpin.

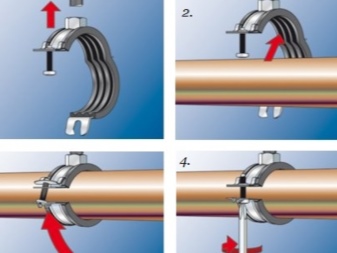

Installation features

The number of clamps to be installed can be calculated both according to the drawing and "by eye" directly on the spot. Special signs are left in the designated places. Holes are drilled exactly according to the marking, which must correspond to the fasteners used. The clamps are first fixed to the support and only then to the object being held. Fixation is carried out strictly by the method that is structurally optimal for a particular clamping unit.

Worm gear clamps are mainly used to seal pneumatic and hydraulic lines. The structure initially includes a screw or bolt for tightening. In combination with a special tape, the hardware makes up a stepless plane. It will allow you to evenly tighten the pipe and seal the joints.

The screw heads are different: hexagonal, with a shoulder, with a slotted or cross-shaped groove. The working tool is selected accordingly. When the propeller turns, the body hits the hooks. Therefore, it will reliably hold on to the screed. Worm gear clamps can be installed and removed at least 50 times.

As for the plumbing products, they are tightened using hex nuts and bolts. A plastic clamp for plumbing, although inferior in strength to a steel analogue, is cheaper and is optimally combined with a PVC pipe. A metal clamp with one mounting socket is only suitable for certain pipe dimensions. If there are two fasteners, it will be possible to adapt the product to pipes of different sizes. Plumbing fasteners after installation in the "ears" are usually tightened with keys.

See below for more details.

The comment was sent successfully.