All About U-Clamps

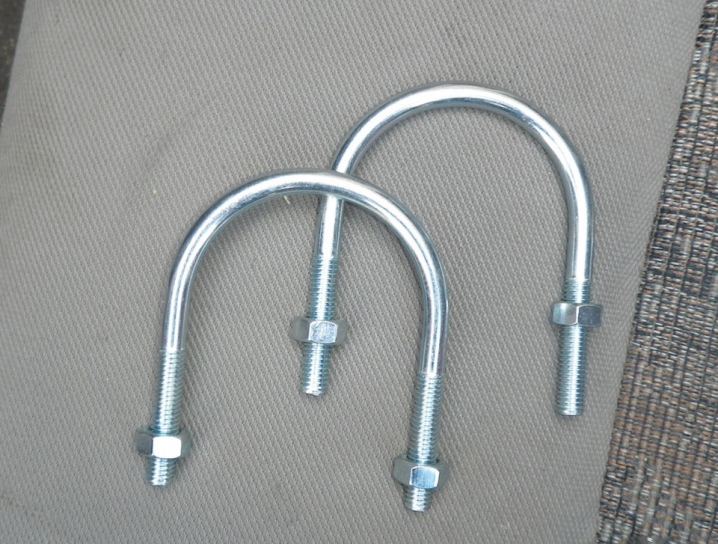

U-clamps are quite widespread. Today, there is not only a stainless steel clamp-bracket for attaching pipes, but also other types of such products. Their sizes and other features are clearly fixed in GOST - and all such subtleties must be clarified in advance.

General characteristics

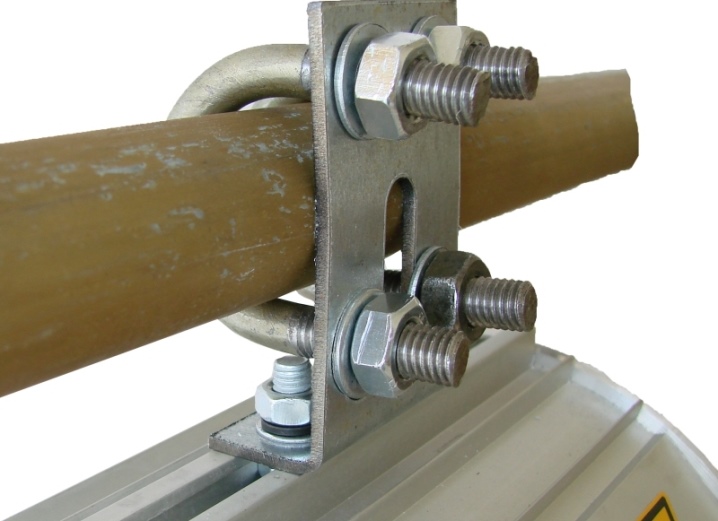

When describing U-clamps, it is imperative to take into account that their key characteristics are fixed in GOST 24137-80. The pipe or hose can be attached with similar fasteners to the surface of a metal sheet of any shape. These products are quite reliable. It is worth noting that in terms of resistance to adverse factors, there is practically no real difference between U-shaped brackets and rings equipped with bolts.

The bracket necessarily has threaded ends. Usually they are equipped with special strips. To obtain the staple itself, a rubber inner layer is often used.

It is not simple, but necessarily microporous rubber. Such a substance perfectly dampens vibrational vibrations that can occur in pipelines.

Features of production

As already mentioned, in the production of clamps, domestic firms are guided by GOST 1980. Foreign companies are free from such a requirement, but it is necessary to find out which foreign standard a particular product meets and whether such characteristics are satisfied. In Russian practice, the most widespread production of U-shaped hardware based on carbon steel. The dimensions are practically not limited, it is possible to apply a galvanic protective coating.

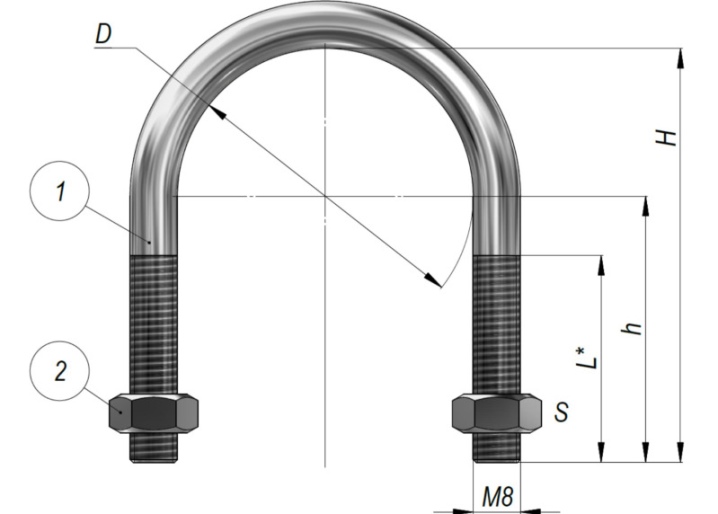

The upper "arc" in the shape of the letter U is the best guarantee of reliable holding of the pipe along the entire section. The nuts included in the kit must comply with GOST 5915-70. Experienced technologists always choose only solutions based on calibrated rolled products. Clamps made from it will have perfect curl. Scrupulously accurate geometry is also required.

Of course Responsible manufacturers subject their products to multiple quality checks to ensure they meet official standards. It is often the practice to equip clamps with additional mounting plates. In addition to standard sizes, you can order products of original dimensions. Heat treatment of parts is carried out at the request of the customer.

The raw material for the manufacture of clamps is a metal circle with a cross section of Ф6 - Ф24.

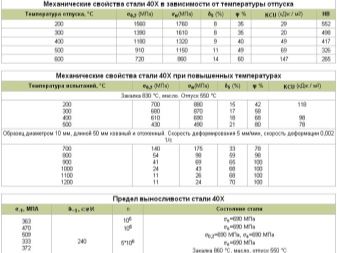

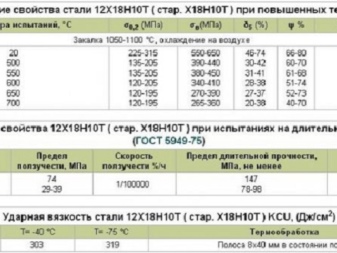

In order to produce clamps that differ from standard clamps, the client can provide his own design and technical documentation, especially drawings. High accuracy and excellent workmanship are guaranteed, final control is carried out according to a verified procedure. The technology as a whole is debugged, and therefore the production time of the clamps is minimal. Depending on the nuances of the technology, steel of the following categories can be used:

-

3;

-

20;

-

40X;

-

12X18H10T;

-

AISI 304/321;

-

AISI 316L and some other types.

Scope of operation

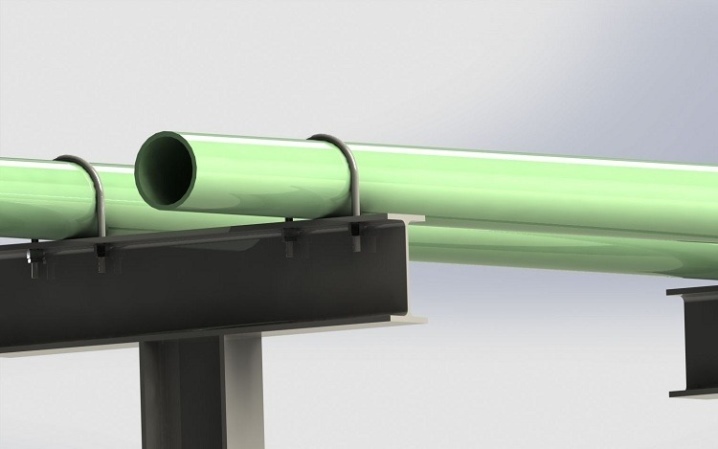

The bracket can be required, of course, for attaching pipes. But its area of use does not end there. You can use similar products to connect other important elements. It is allowed to work with pipes of various types. The U-clamp is acceptable for both vertical and horizontal pipe installation.

The main areas of application for the U-Clamp are:

-

fastening pipes and various beams;

-

placement of road signs and similar signs;

-

keeping television and other antennas in place;

-

ensuring the tightness of various technological systems without installation;

-

installation work on many types of surfaces and supports;

-

fastening of structural parts in exhaust systems of cars (according to the "pipe in pipe" principle).

The pipes to be installed will be fixed firmly and reliably, they can be operated for a long time. But clamps can be used not only during installation, but also when repairing the pipeline.

They are great help if other options for dealing with deformation are impossible. Also, U-shaped clamps are used when repairs must be completed quickly and without interruption in fluid circulation.

Installation of hardware on steel, plastic, cast iron and asbestos-cement pipes is allowed.

It will be possible to repair the pipeline if:

-

fractures;

-

fistula;

-

cracks;

-

mechanical defects;

-

other deviations from the norm.

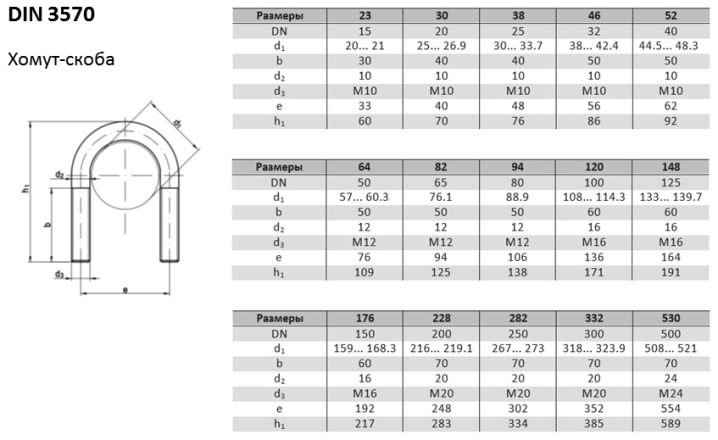

Types and sizes

The main differences between the products are related to their cross-sections and to the main construction materials. Possible cross-sections for serial products are at least 16 and maximum 540 mm. Products conforming to the 1980 standard may have the following parameters:

-

section 54 cm and weight 5 kg 500 g;

-

section 38 cm and weight 2 kg 770 g;

-

diameter 30 cm and weight 2 kg 250 g;

-

diameter 18 cm and weight 910 g;

-

circumference 12 cm and weight 665 g;

-

circumference 7 cm and weight 235 g.

Various materials can be used for the manufacture of fastening clamps (staples). Most often, carbon steel is chosen. It is allowed to use both stainless alloys and galvanized metal; the thickness of the zinc layer varies from 3 to 8 microns. A wide variety of steel grades can be used.

In any case, the strength class must be at least 4.6; an important difference between the individual modifications is the tension level, which determines the scope of application and ease of installation.

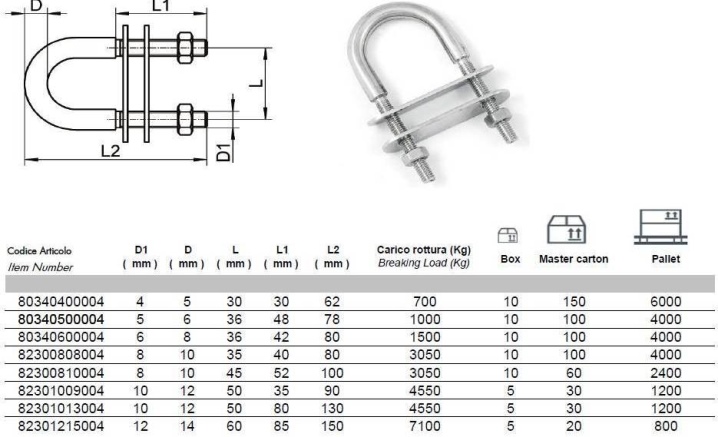

The delivery set usually contains, in addition to the bracket itself, a couple of nuts. The length of the bent rod can vary from 30 to 270 mm. The rod diameter can be 8-24mm. Shipment and daily storage of clamps is possible only in boxes. 1 box contains from 5 to 100 units of finished products.

Clamps are sold by the following leading manufacturers:

-

Fischer;

-

MKT;

-

Golz;

-

Rolltuff;

-

domestic "Energomash".

Differences can also relate to:

-

standard sizes;

-

thickness;

-

dimensions of connecting nuts;

-

permissible workloads;

-

critical (destructive) load level.

What a U-clamp 115 GOST 24137 looks like, see below.

The comment was sent successfully.